H ,

.:i= CUSTOMER RESPONSIBILITIES

;

..... \

MAINTENANCE SCHEDULE

Fill in dates as you complete regularservice

C"eckfordamagedorwornpa.s

Check for loose fasteners and parts

Check chain tension'

Check chain sharpness

Check guide bar'condition

Check guide bar lube

Clean unit & labels

Clean air filter

CleaWinspect spark arrestor screen & inspect muffler

Replace spark plug

R'ep'i'acef ,er .............. 1.......

Beforet After

Use Use

v" !

,/

€"

€"

Every Every Yearly Service Dates

5 Hrs. 25 Hrs.

...............

,,u

v"

GENERAL RECOMMENDATIONS

The warranty on this unitdoes notcover items that have

been subjected tooperatorabuseor negligence.Toreceive

fullvaluefrom the warranty,the operatormustmaintainunit

as instructedin this manual.

Some adjustments will need to be made periodically to

properlymaintain your unit.

All adjustmentsinthe=Service andAdjustments"sectionof

this manual should be checked at Ieast once each season,

• Once a year, replacethe sparkplug, replaceair filter ele-

ment and check guide bar and chain for wear. A new

spark p{ug and a clean/new air filter element assures

properair-fuel mixture and helps your engine run better

and last longer.

• Followthe maintenance schedulein this manual.

WARNING:

DISCONNECT THE SPARK PLUG BEFORE

PERFORMING MAINTENANCE EXCEPT FOR

CARBURETOR ADJUSTMENTS.

INSPECTTHE ENTIRE UNIT. REPLACE DAM-

AGED PARTS. CHECK FOR FUEL LEAKS

AND MAKE SURE ALL FASTENERS ARE IN

PLACE AND SECURELY FASTENED.

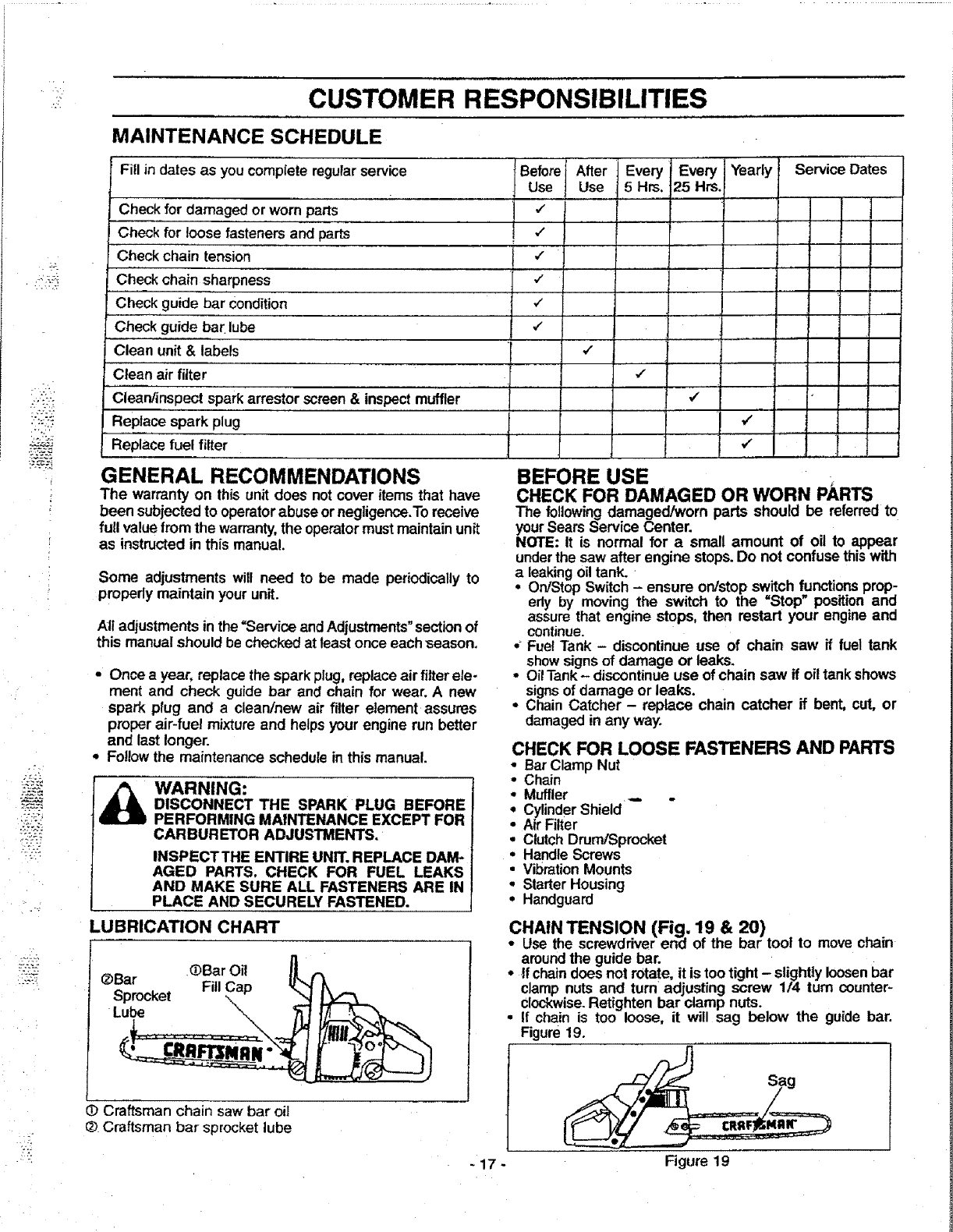

LUBRICATION CHART

@Bar Oil

®Bar

Sprocket FillCap

Lube

(DCraftsman chain saw bar oil

® Craftsman bar sprocket lube

-17-

BEFORE USE

CHECK FOR DAMAGED OR WORN PARTS

The followingdamaged/worn parts should be referred to

your Sears Service Center.

NOTE: It is normal for a small amount of oil to appear

underthe saw after engine stops.Do not confuse thiswith

a leakingoiltank.

• On/Stop Switch ensure on/stop switch functionsprop-

erly by moving the switch to the =Stop" position and

assurethat engine stops, then restart your engine and

continue.

o_Fuel Tank - discontinue use of chain saw ff fuel tank

show signs of damage or leaks.

• Oil Tank - discontinue use of chain saw if oil tank shows

signs of damage or leaks.

• Chain Catcher- replace chain catcher if bent, cut, or

damaged in any way,

CHECK FOR LOOSE FASTENERS AND PARTS

• BarClamp Nut

• Chain

• Muffler ... .

• CylinderShield

• AirFilter

° ClutchDrum/Sprocket

• Handle Screws

• VibrationMounts

° StarterHousing

• Handguard

CHAIN TENSION (Fig. 19 & 20)

Use the screwddver enid of the bar tool to movechain

aroundthe guide bar.

• If chaindoesnot rotate, it is tootight - slighttyloosenpar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise.Retighten bar clamp nuts.

• If chain is too loose, it will sag below the guidebar.

Figure19.

Sag

Figure 19