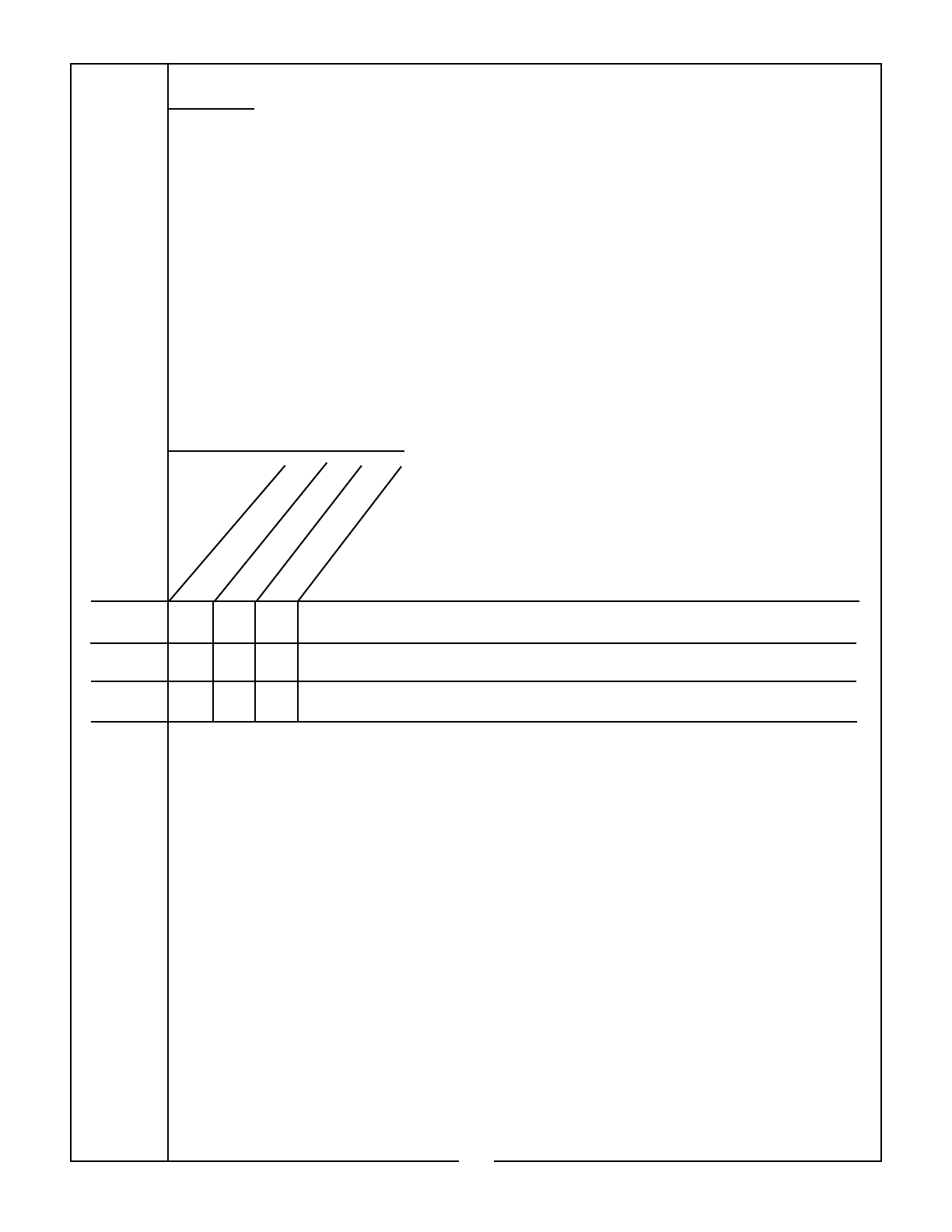

V-belts

The spring is to be tightened so that the end of the spring is in alignment with the edge of the

bracket, as shown.

Models HM2007 - HM2008 - HM2009 (D) = 0 mm

New V-belts should be re-tightened after a few hours operation. Inspection of V-belts is carried out

through hole (E). The front part of the belt guard can easily be removed.

Lubrication (Lubricants, - see page 46)

Before starting to use a new machine: Check the oil level of the gearbox and the cutterbar and

lubricate the machine and driveline. See pages 32 & 33 and observe all lubrication decals.

Lubrication generally

③

① - ②

(A)

(B)

(C)

●●

5 Driveline with overrun clutch

● ● 2 Swivel link (twice daily)

● ●

All movable parts should be lubricated with oil or grease once-twice/daily -

be especially attentive to the sliding surfaces shown.

Every 10th hour (daily)

Every 40th hour

Number of nipples

*

*

All universal crosses and bearings in the plastic tubes of the PTO shaft are to be lubricated every 8

- 10 hours of operation. Profile tubes should be separated, cleaned and lubricated after 40 hours

use. Use lithium grease.

NOTICE

Regularly check the driveline. Any damage or lack of lubrication to the hollow shaft may cause the

PTO shaft on the tractor or machine to be damaged beyond repair.

During still periods (one week or more): Wash and lubricate the machine, spray it with a thin

layer of rust protecting oil - especially important at cutting discs.

The hydraulic lifting cylinder of the machine: During prolonged storage press the piston rod

into the piston housing (remove the complete lifting cylinder at the connection link on the gearbox),

or coat the exposed surface of piston rod with grease.

31