2 Remove foam pre-cleaner. Spark Plug-Clean and reset gap at .030" every 1 00

a. Wash pre-cleaner in liquid detergent and warm hours of operation.

water to remove dirt. NOTE: Do not blast clean spark plug. Spack plug

b. WrElp pre-cleaner in cloth and squeeze dry. should be cleaned by scraping or wire brushing and

.washing with a commercial solvent.

c. Saturate foam in engine 011. Squeeze to

remove excess oil. Caution: Sparking can occur if wire terminal does not

f f .d fit firmly on spark plug. Reform terminal if necessary.

3. Remove two nuts rom top 0 cartrl ge.

.Spark Arrester Equipped Muffler-If engine muffler

4. Remove cartridge and clean air cleaner body is equipped with spark arrester screen assembly,

carefully to prevent dirt from entering carburetor. remove every 50 hours for cleaning and inspection.

Brush ,jirt from lower air cleaner body Into duct. Replace if damaged.

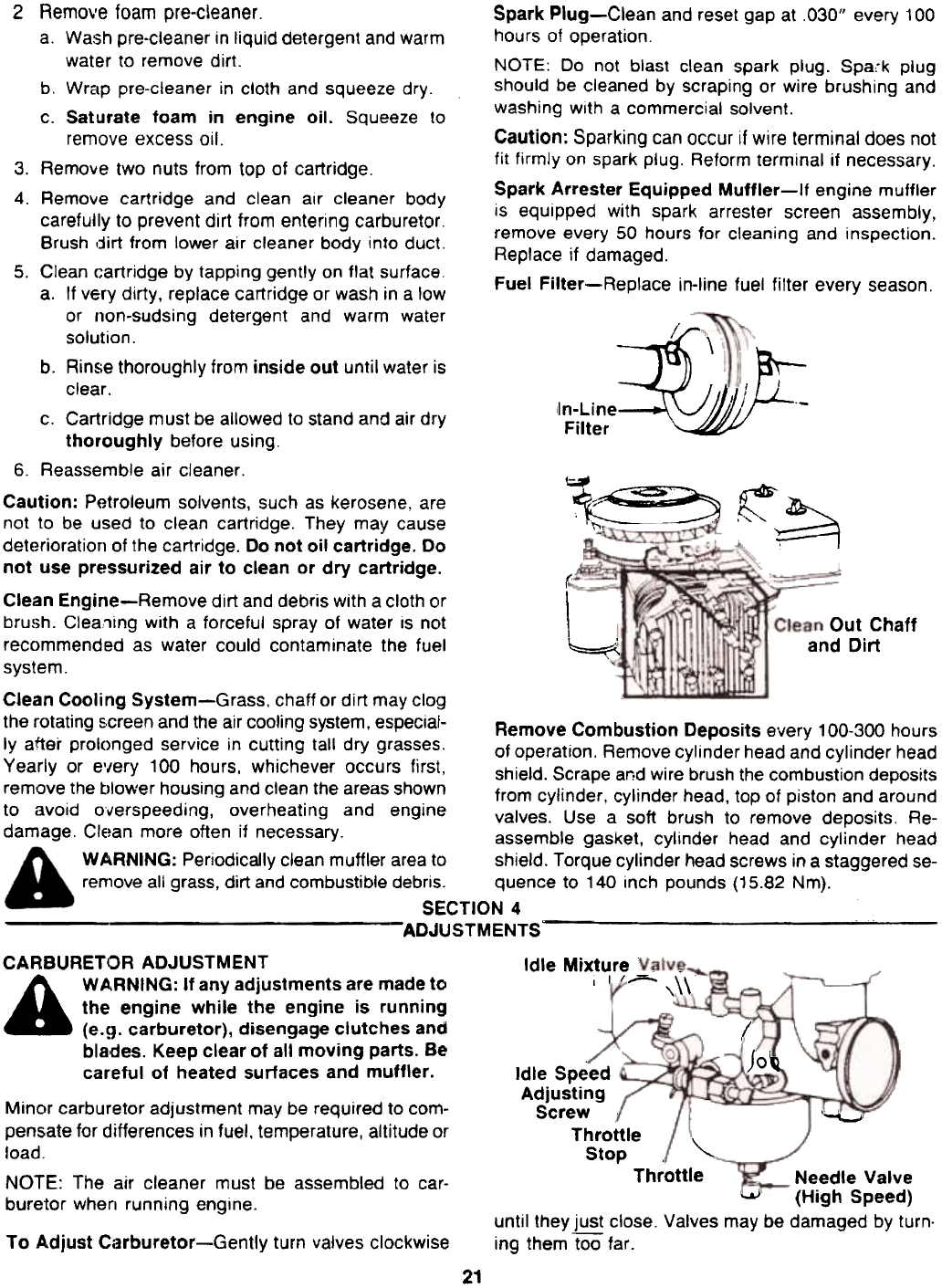

5. Clean cartridge by tapping ~ently on flat ~urface Fuel Filter-Replace in-line fuel filter every season.

a. If very dirty, replace cartridge or wash In a low

or non-sudsing detergent and warm water

solution.

b. Rinse thoroughly from inside out until water is

clear.

.

d I

c. Cartridge must be allowed to stand and air ry

thoroughly before using.

6. Reassemble air cleaner. f

Caution: Petroleum solvents, such as kerosene, are

not to be used to clean cartridge. They may cause

deterioration of the cartridge. Do not oil cartridge. Do

not use pressurized air to clean or dry cartridge. (

Clean Engine-Remove dirt and debris with a cloth or

\brush. Clea,1ing with a forceful spray of water is not

recommended as water could contaminate the fuel I

system.

Clean Cooling System-Grass. chaff or dirt may clog ---~-

the rotating s,creen and the air cooling system, especial- Remove Combustion Deposits every 100-300 hours

Iy after prolonged service in cutting tall dry grasses. of operation. Remove cylinder head and cylinder head

Yearly or e'/ery 100 hours, whichever occurs first, shield. Scrape ar,d wire brush the combustion deposits

remove the blower housing and clean the areas shown from cylinder, cylinder head, top of piston and around

to avoid ol/erspeeding, overheating and engine valves. Use a soft brush to remove deposits. Re-

damage. Clean more often if necessary. assemble gasket, cylinder head and cylinder head

WARNING: Periodically clean muffler area to shield. Torque cylinder head screws in a staggered se-

remove all grass, dirt and combustible debris. quence to 140 inch pounds (15.82 Nm).

SECTION 4

-

~ADJUSTMENTS.

~ \

I IIn-Line

1/_-

Filter

:;.?

~~~::::~~~ ~

; :-- -,~

~

Out Chaff

and Dirt

~

CARBURETOR ADJUSTMENT

A WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), disengage clutches and

bla,des. Keep clear of all moving parts. Be

careful of heated surfaces and muffler.

Idle

Mixture r ~

i I / =.. \ \ \.

Ijo~

y

-'

Idle Speed I

Adjusting

Screw I

Throttle

Stop

."

Throttle

Needle Valve

\..I.J (High Speed)

until they just close. Valves may be damaged by turn-

ing them -roo far.

Minor carburetor adjustment may be required to com-

pensate for differences in fuel. temperature, altitude or

load.

NOTE: The air cleaner must be assembled to car-

buretor wherl running engine.

To Adjust C;~rburetor-Gently turn valves clockwise

21