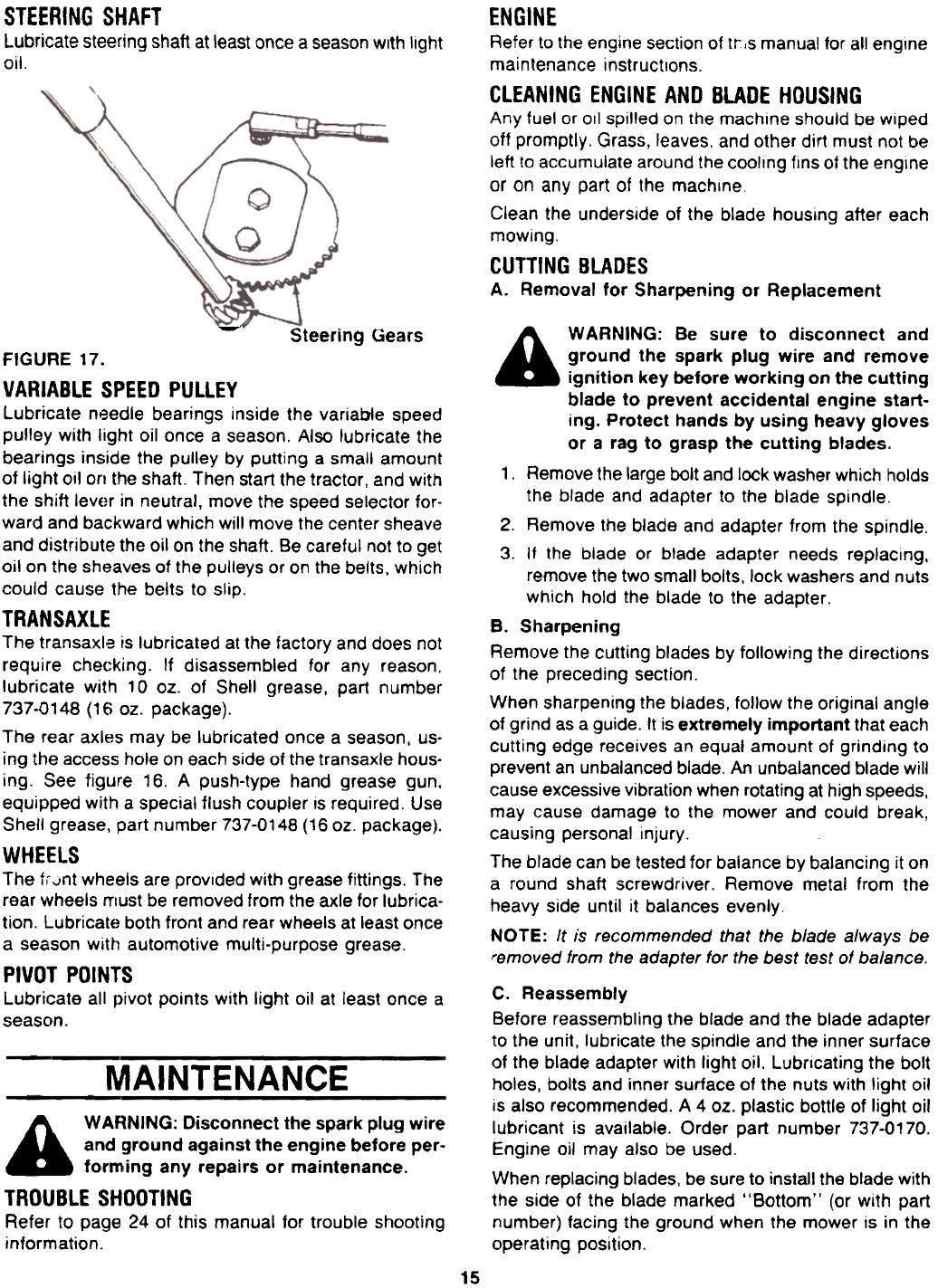

STEERING SHAFT

Lubricate steering shaft at least once a season with light

oil.

ENGINE

Refer to the engine section of Iris manual for all engine

maintenance instructions.

CLEANING ENGINE AND BLADE HOUSING

Any fuel or 011 spilled on the machine should be wiped

off promptly. Grass, leaves, and other dirt must not be

left to accumulate around the cooling fins of the engine

or on any part of the machine

Clean the underside of the blade housing after each

mowing.

CUTTING BLADES

A. Removal for Sharpening or Replacement

-

Steering Gears

A WARNING: Be sure to disconnect and

ground the spark plug wire and remove

ignition key before working on the cutting

blade to prevent accidental engine start-

ing. Protect hands by using heavy gloves

or a rag to grasp the cutting blades.

1. Remove the large bolt and lock washer which holds

the blade and adapter to the blade spindle.

2. Remove the blade and adapter from the spindle.

3. If the blade or blade adapter needs replacing.

remove the two small bolts, lock washers and nuts

which hold the blade to the adapter.

B. Sharpening

Remove the cutting blades by following the directions

of the preceding section.

When sharpening the blades. follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds.

may cause damage to the mower and could break,

causing personal injury.

The blade can be tested for balance by balancing it on

a round shaft screwdriver. Remove metal from the

heavy side until it balances evenly

NOTE: It is recommended that the blade always be

r'emoved from the adapter for the best test of balance.

FIGURE 17.

VARIABLE SPEED PULLEY

Lubricate needle bearings inside the variable speed

pulley with light oil once a season. Also lubricate the

bearings inside the pulley by putting a small amount

of light oil ort the shaft. Then start the tractor, and with

the shift lever in neutral, move the speed selector for-

ward and backward which will move the center sheave

and distribute the oil on the shaft. Be careful not to get

oil on the sheaves of the pulleys or on the belts. which

could cause the belts to slip.

TRANSAXLE

The transaxle is lubricated at the factory and does not

require che(:king. If disassembled for any reason,

lubricate with 10 oz. of Shell grease, part number

737-0148 (16 oz. package).

The rear axles may be lubricated once a season, us-

ing the access hole on each side of the transaxle hous-

ing. See figure 16. A push-type hand grease gun.

equipped with a special flush coupler is required. Use

Shell grease, part number 737-0148 (16 oz. package).

WHEELS

The f, Jnt wheels are provided with grease fittings. The

rear wheels must be removed from the axle for lubrica-

tion. Lubricate both front and rear wheels at least once

a season with automotive multi-purpose grease.

PIVOT POINTS

Lubricate all pivot points with light oil at least once a

season.

MAINTENANCE

C. Reassembly

Before reassembling the blade and the blade adapter

to the unit. lubricate the spindle and the inner surface

of the blade adapter with light oil. Lubricating the bolt

holes, bolts and inner surface of the nuts with light oil

is also recommended. A 4 oz. plastic bottle of light oil

lubricant is available. Order part number 737-0170.

Engine oil may also be used.

When replacing blades, be sure to install the blade with

the side of the blade marked "Bottom" (or with part

number) facing the ground when the mower is in the

operating position.

A WARNING: Disconnect the spark plug wire

and ground against the engine before per-

forming any repairs or maintenance.

TROUBLE SHOOTING

Refer to page 24 of this manual for trouble shooting

information.

15