6 - 32

26.Install the differential axle assembly into the

housing.

27.Install a new filter onto the center section check

valve plate.

28.Install the rotors and stators. Install a stator, then a

rotor (hub to inside), then a stator, then a rotor (hub

to inside), then two stators.

29.Install the brake bolt (with nut) into the upper

housing.

30.Apply the sealant to the lower housing.

NOTE:

Sealant must be of good quality, oil and heat

resistant.

Position the lower housing onto the upper housing and

secure with assembly bolts. Torque the bolts from

135-165 in. lbs. (8-10 Nm).

NOTE:

The bolts around the front of the housing are

installed simultaneously at our factory. The order in

which you torque them is not important.

31.After torquing all bolts, wipe off any excess sealant

from the seam of the housing.

32.Reposition the transaxle assembly and check the

bypass actuator and axle shafts for freedom of

movement. The axle should not lock up but may be

tight, while the bypass actuator must rotate freely.

33.Torque the nut on the brake bolt from 120-185 in.

lbs. (7-11 Nm).

34.Install a new lip seal on the displacement control

shaft and bypass actuator shaft.

35.Install the brake pins and brake arm.

36.Adjust the brake clearance as described in the

brake adjustment section.

37.Install the control arm and friction pack.

38.Install the bypass actuator arm and retaining ring.

Use care to avoid over extending the retaining ring.

39.Prior to adding oil to the transmission it is

recommended that you test for leaks. This may be

performed with a small hand pump or by using

compressed air and a regulator. Do not allow more

than 10 PSI to be applied or seal damage may

occur. To locate a leak, apply a soap mixture

around the housing seam and at all lip seals. Do

not submerge unit or the brake will be damaged.

Oil Fill & Start-Up Procedures

Fill the transmission with a 20W-50 engine oil. The

correct volume for fill should be 2-1/2 quarts (2.4 L).

It is recommended that the unit be purged prior to

installing into the unit frame. The following is the

suggested purging procedures for repaired transaxle.

1. Spin the input shaft in a clockwise direction at

1000-1500 RPM. This may be performed in a drill

press (or equivalent).

2. Engage (actuate) the bypass.

3. Stroke the control lever forward for five seconds

and then reverse for five seconds. Do this three

times in each direction.

4. Return the control lever to neutral.

5. Disengage the bypass.

6. Stroke the control lever forward for five seconds

and then reverse for five seconds. Do this three

times in each direction.

NOTE:

It may be necessary to repeat these steps in

the vehicle to fully purge the transmission.

7. Check the oil level after fully purging the unit of air.

It should be between 1.25-1.62" (3.1-4.1 cm) from

the top of the housing.

8. After installing the transmission, make sure all

linkages and actuators are functioning properly.

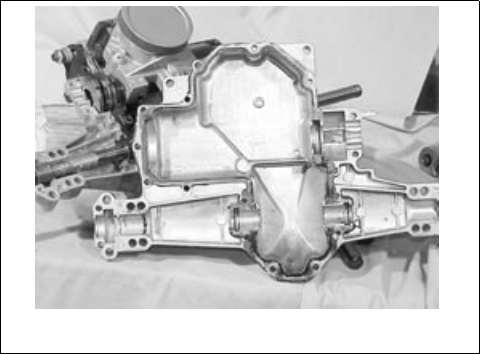

Figure 40

936-24