4 - 18

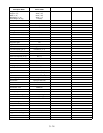

4.11 CHECKING THE TRANSMISSION

FLUID (HYDRO)

The transaxle is filled and tested at the factory and

should not require fluid when the unit is put into

service. Inspect the transaxle for leaks or damage to

the housing. If leakage is observed, do not operate

until the leakage is repaired.

Check the oil level and fill to the correct level if needed.

The oil should be between 1.25 and 1.60" from the top

of the housing in the 310-0750 axle. It may be checked

by removing the expansion hose. Typically, an API

classification CG/CD engine oil is used with a viscosity

range equivalent to 20W50.

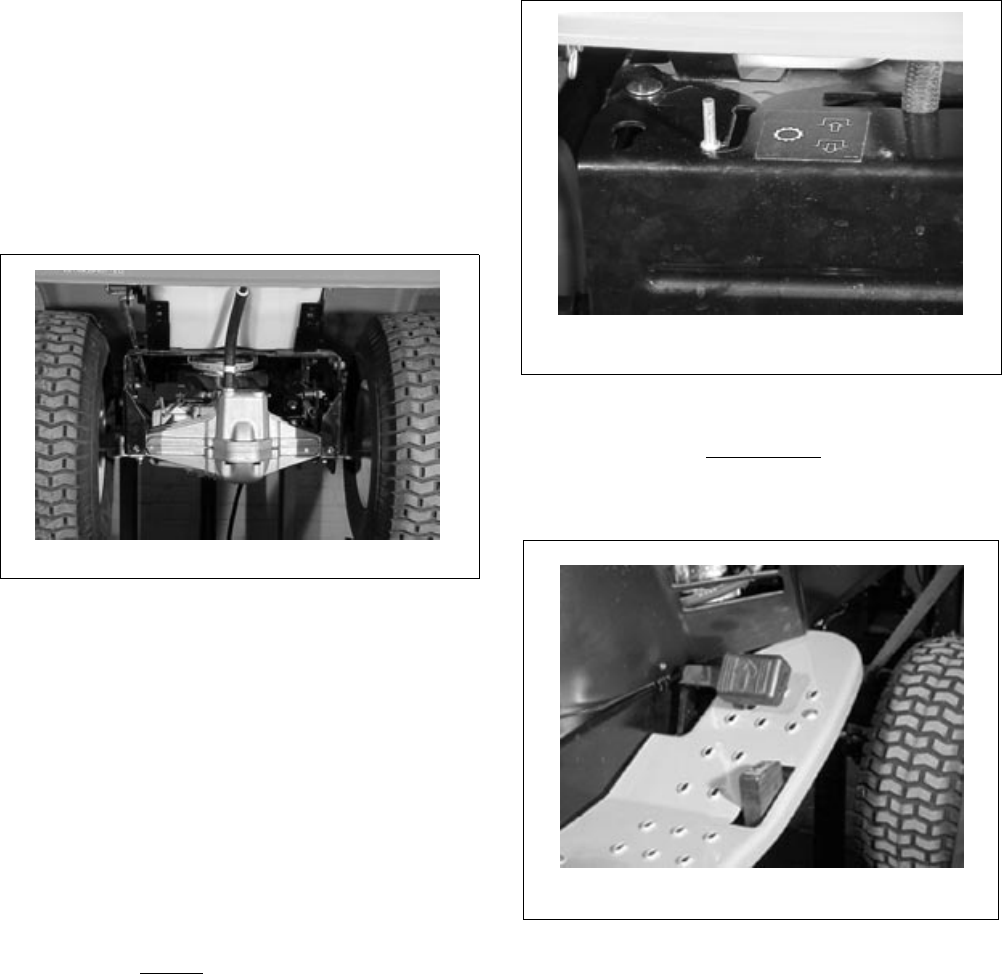

4.12 PRIMING THE TRANSMISSION

(HYDRO)

The following is suggested for the priming of new or

repaired transaxles to assure proper operating

performance.

1. Locate the unit on a flat level surface to limit the

chance of the unit rolling while performing the

following procedures.

2. Actuate the bypass

(freewheel control).

3. Start engine and run at low idle.

4. Stroke the travel control pedal

forward for five

seconds and then reverse for five seconds. Do this

three times in each direction.

5. Return the travel control to neutral.

6. Disengage the bypass and drive the unit forward

and then reverse. Do this three times each way for

a distance of approximately five feet.

7. Some units may require repeating the previous six

steps to achieve proper operating performance.

4.13 CHECKING THE PTO CLUTCH

Measure Clutch Coil Resistance:

1. Turn engine and power take off (PTO) switch off.

2. Disconnect clutch wire connections.

3. Set meter to check ohms.

4. Connect meter leads in clutch connector.

936-7

Figure 9

Figure 10

936-8

Figure 11

936-9