CARBURETOR ADJUSTMENTS

A WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), disengage all clutches

and blades. Keep clear of all moving parts.

Be careful of heated surfaces and muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load. Refer to separate engine manual

for carburetor adjustment information.

NOTE: A dirty air cleaner will cause an engine to runrough.

Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

LUBRICA TION

WARNING: Always stop engine and

disconnect spark plug wire before clean-

ing, lubricating or doing any kind of work

on lawn tractor.

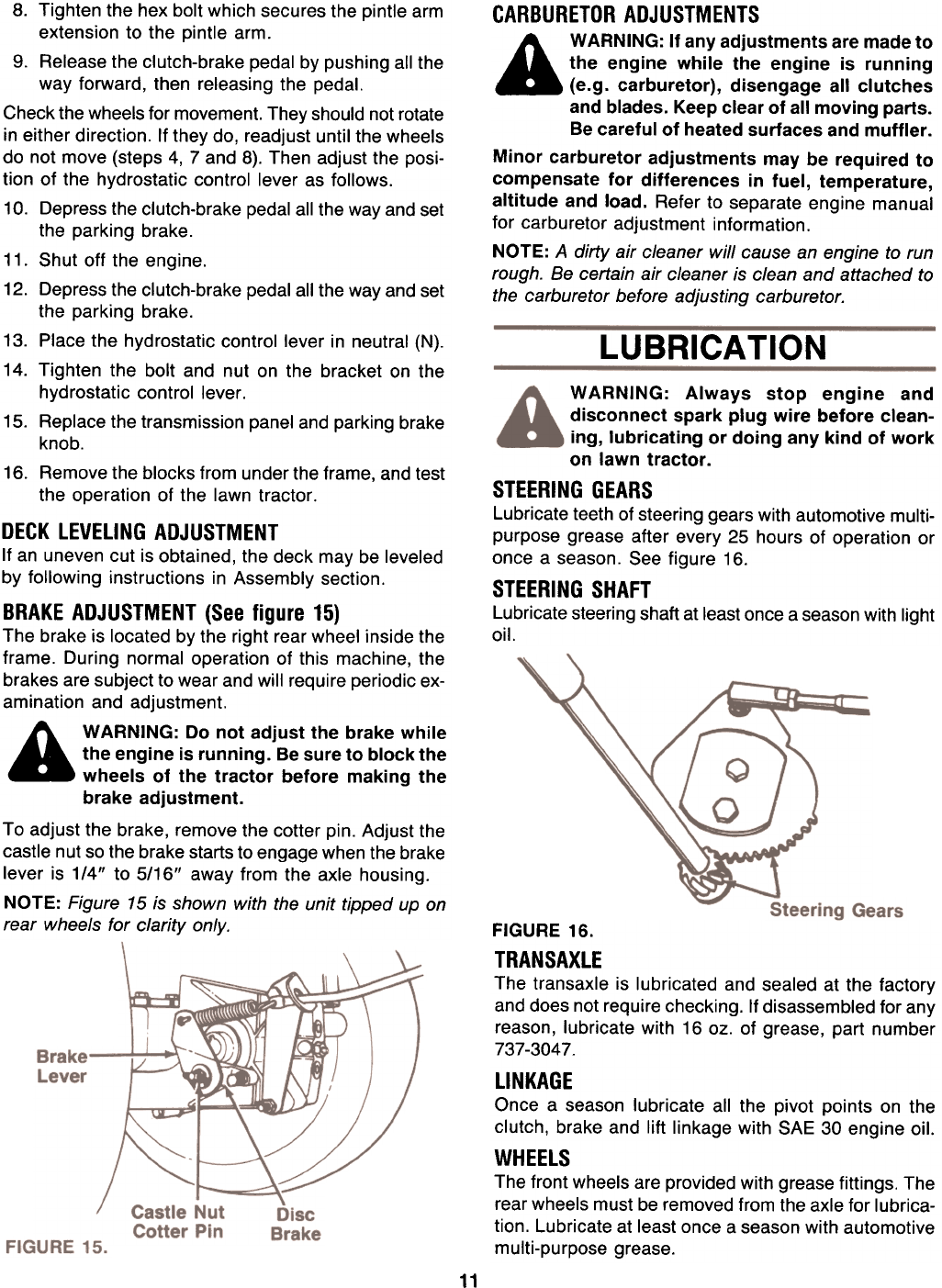

STEERING GEARS

Lubricate teeth of steering gears with automotive multi-

purpose grease after every 25 hours of operation or

once a season. See figure 16.

STEERING SHAFT

Lubricate steering shaft at least once a season with lightoil.

8. Tighten the hex bolt which secures the pintle arm

extension to the pintle arm.

9. Release the clutch-brake pedal by pushing all the

way forward, then releasing the pedal.

Check the wheels for movement. They should not rotate

in either direction. If they do, readjust until the wheels

do not move (steps 4, 7 and 8). Then adjust the posi-

tion of the hydrostatic control lever as follows.

10. Depress the clutch-brake pedal all the way and set

the parking brake.

11. Shut off the engine.

12. Depress the clutch-brake pedal all the way and set

the parking brake.

13. Place the hydrostatic control lever in neutral (N).

14. Tighten the bolt and nut on the bracket on the

hydrostatic control lever.

15. Replace the transmission panel and parking brake

knob.

16. Remove the blocks from under the frame, and test

the operation of the lawn tractor.

DECK LEVELING ADJUSTMENT

If an uneven cut is obtained, the deck may be leveled

by following instructions in Assembly section.

BRAKE ADJUSTMENT (See figure 15)

The brake is located by the right rear wheel inside the

frame. During normal operation of this machine, the

brakes are subject to wear and will require periodic ex-

amination and adjustment.

A WARNING: Do not adjust the brake while

the engine is running. Be sure to block the

wheels of the tractor before making the

brake adjustment.

To adjust the brake, remove the cotter pin. Adjust the

castle nut so the brake starts to engage when the brake

lever is 1/4" to 5/16" away from the axle housing.

NOTE: Figure 15 is shown with the unit tipped up on

rear wheels for clarity only.

FIGURE 16.

TRANSAXLE

The transaxle is lubricated and sealed at the factory

and does not require checking. If disassembled for any

reason, lubricate with 16 oz. of grease, part number

737-3047.

LINKAGE

Once a season lubricate all the pivot points on the

clutch, brake and lift linkage with SAE 30 engine oil.

WHEELS

The front wheels are provided with grease fittings. The

rear wheels must be removed from the axle for lubrica-

tion. Lubricate at least once a season with automotive

multi-purpose grease.

11