Operation 15

MAN0884 (08/15/2011)

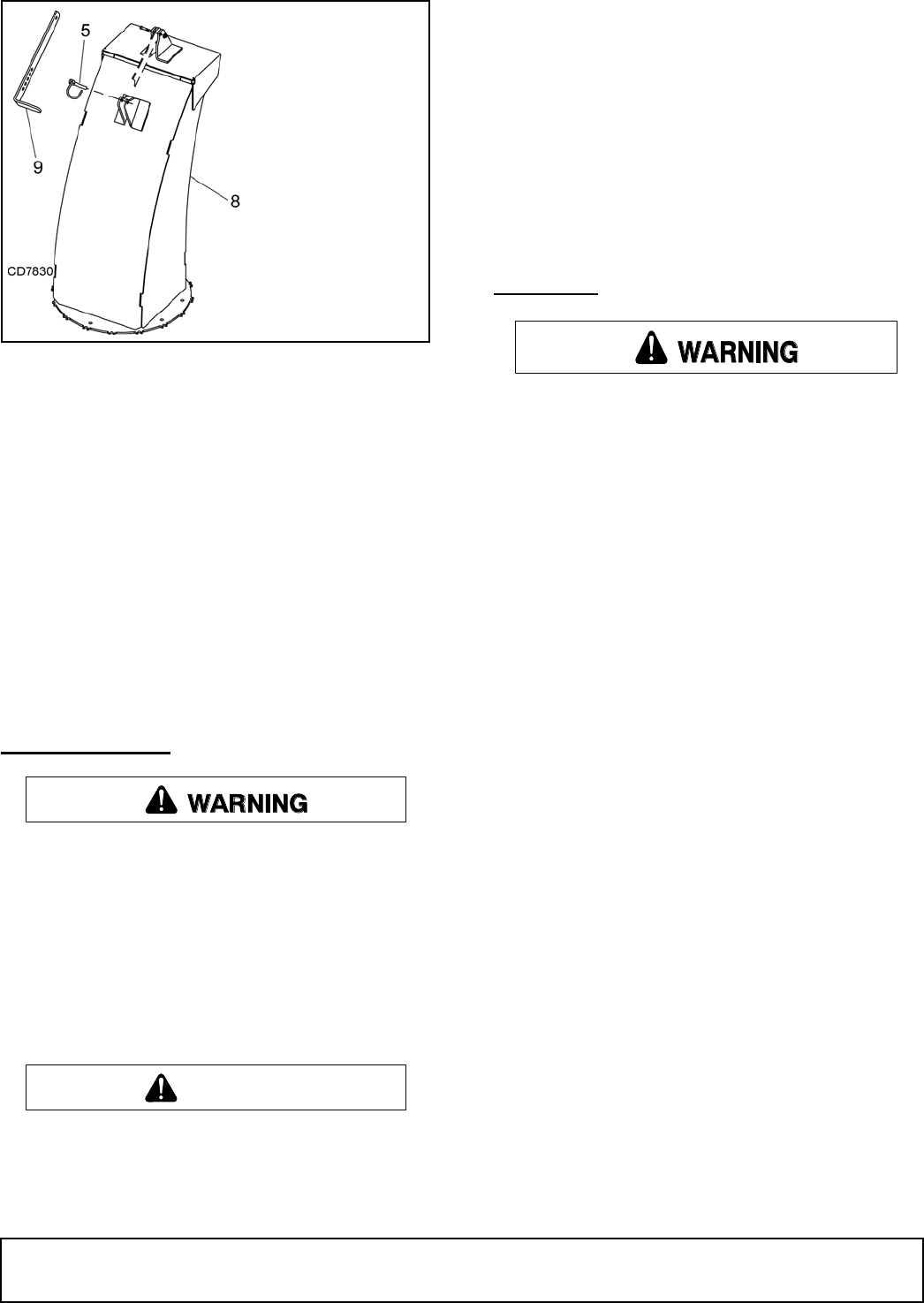

Figure 8. Discharge Chute Position

■ Keep bystanders away from equipment.

■ Wear appropriate hearing protection.

5. Depth of cut can be controlled with the skid shoes

or by tilting the blower forward or backward. Exces-

sive forward or backward tilt may cause U-joint to

flutter resulting in PTO shear bolt failure. Do not

run the PTO shaft at more than a 15° angle.

6. Allow the snowblower to work its way through the

snow rather than forcing it.

7. In deep snow it may be necessary to raise the

snowblower for the first pass through and clean up

the remainder with a second pass.

8. Do not feed snow through snowblower when rais-

ing or lowering.

TRANSPORTING

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up result-

ing in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Never allow riders on power unit or attachment.

Do not operate PTO during transport.

Always comply with all state and local lighting

and marking requirements.

NOTICE

■ Do not exceed 20 mph (32km/h). Reduce speed

on rough roads and surfaces.

When transporting snowblower, review and follow this

procedure:

■ Be sure all bystanders are clear of machine.

■ Be sure that machine is securely attached to

tractor and all retainer pins are installed.

■ Raise machine.

■ Do not allow riders.

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

After season's use, machine should be thoroughly

inspected and prepared for storage. Repair or replace

any worn or damaged components to prevent any

unnecessary down time at start of next season.

To insure a long, trouble free life, this procedure should

be followed when preparing unit for storage.

1. Clear area of bystanders.

2. Thoroughly wash machine to remove all dirt, mud,

debris or residue.

3. Check auger, fan and drivelines for damage or

entangled material. Remove the entangled mate-

rial. Repair or replace damaged parts.

4. Inspect all hydraulic hoses, fittings, lines and cou-

plers. Tighten any loose fittings. Replace any hose

that is cut, nicked or abraded or is separating from

crimped end of fitting.

5. Change oil in gearbox.

6. Lubricate all grease fittings. Make sure that all

grease cavities have been filled with grease to

remove any water residue from washings.

7. Touch up all paint nicks and scratches to prevent

rusting.

8. Move to storage area.

9. Select an area that is dry, level and free of debris.

10. Unhook from tractor.

11. Store machine in an area away from human activ-

ity.

12. Do not allow children to play on or around stored

machine.

5. Clevis Pin

8. Discharge Chute

9. Adjustment Strap

CAUTION