16 Dealer Service

15148 (Rev. 2/9/2007)

Proper seal installation is important. An improperly

installed seal will leak and could cause bearing failure.

Lightly coat area of housing where seals seat with Per-

matex

®

.

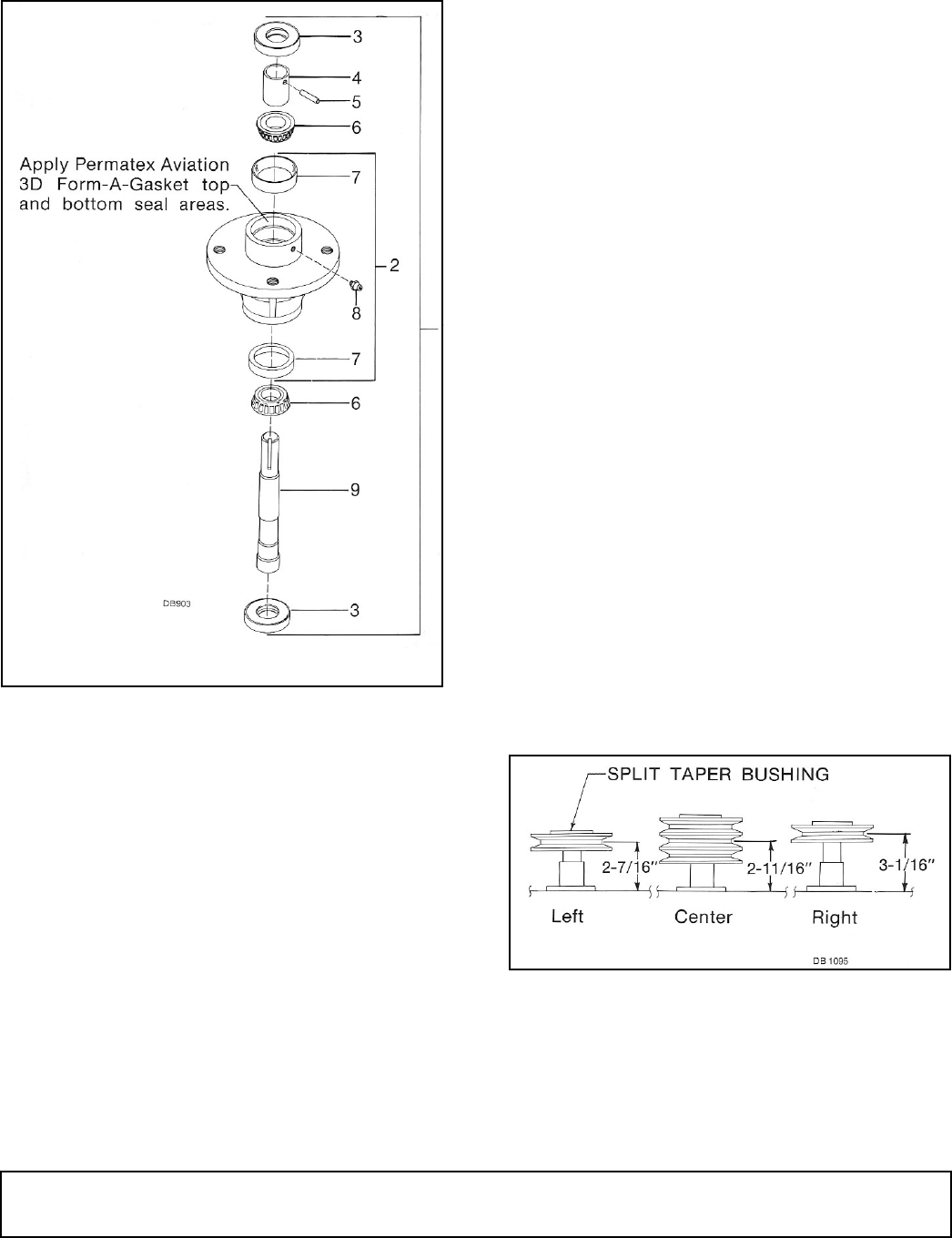

Figure 8. Spindle Assembly

Pull the rubber portion of seal back and locate spring.

Apply a thin coat of lubricant to bottom seal and install

with spring up toward center of housing.

Place seal squarely on housing. Select a piece of pipe

or tubing with an outside diameter that will set on out-

side edge of seal. A tube that is too small will bow seal

cage.

Carefully press seal into housing, preventing distortion

to metal seal care. Seal should seat firmly and squarely

against machined shoulder in housing.

Make sure seal lip did not roll under. Distortion to seal

cage or damage to seal lip with cause seal to leak.

Damaged seals must be replaced.

Apply a thin coat of lubricant to top seal and install with

spring up away from center of housing. Top seal should

be flush with, to 1/16" above, housing.

NOTICE

■ Bearing adjustment is set by pressing sleeve

against bearing until proper adjustment is attained.

Adjustment is maintained by drilling a hole through

sleeve (4) and spindle shaft (9) and inserting a

spring pin.

■ Bearing cups and cones may vary; therefore it

is necessary to drill a new hole through shaft (9) to

maintain proper adjustment of new bearings. Drill

hole 90° to the original hole.

Place a rag over seal for protection and drill a 3/16"

hole 9/32" down from top of sleeve (4) and 90° to origi-

nal hole in shaft (9). Drive spring pin (5) through sleeve

and shaft to hold bearing adjustment. Make sure spring

pin does not extend past outer diameter of sleeve on

either side. File pin off if necessary.

Lubricate spindle with a medium grade grease, venting

top seal with a blunt edged tool such as a letter opener

while filling with grease.

Rotate housing on spindle shaft, checking for free

movement.

Installation

Insert spindle through bottom of mower deck and

secure with four mounting bolts. Be sure to position

grease fittings toward lubrication access areas. Refer

to Lubrication in Owner Service section, page 12.

Install pulley, split taper bushing and key on spindle

shaft and adjust to height indicated. Alternately tighten

split taper bushing bolt to 12 lbs-ft. Check to make sure

pulley is adjusted to the proper dimensions as shown in

Figure 9.

Dimensions are from top of mower deck to pulley cen-

terline.

Figure 9. Blade Spindle Installation

1. Spindle Assembly

2. Spindle Housing &

Bearing Cups

3. Seal

4. Sleeve

5. Spring Pin

6. Bearing Cone

7. Bearing Cups

8. Grease Fitting

9. Spindle Shaft,

Left Hand Threads