78

Maintenance Instructions ADJUSTMENTS

Blade Clutch (PTO)

Clutch Disengagement/Brake Action

The declutched or disengaged position of the

blade clutch idler pulley is adjustable and is set to

give belt release without excessive slack and to

apply the blade brake. The blade brake is activated

by linkage to the clutch idler pulley mechanism. The

brake is designed to stop the blades within five (5)

seconds after disengaging the clutch.

Use the following procedure to check and adjust

clutch disengagement and brake action:

1. Use the adjustment nut on the brake band (refer

to PTO Clutch Disengagement Adjustment

illustration) to set the position of the clutch idler

pulley in the declutched position. Adjust the

declutched pulley position to give 1/2 in.

(13 mm) pulley travel from “clutch engaged”

to “clutch disengaged.” To check and adjust the

pulley travel, first engage the clutch, then mea-

sure the distance the pulley moves down as the

clutch is disengaged.

2. After the pulley travel is set, check blade brake

action as described in CHECKING/SERVICING

the Blade Brake Action in this section. If the

brake does not stop the blades within five (5)

seconds, check the following:

a. Check clearance between the clutch idler

pulley and the motor mount when the pulley

is in the declutched position. If there is no

clearance and the idler pulley rests on the

frame, the blade brake will not be applied

when the clutch is disengaged. Normally,

this problem would be caused by a short

engine PTO drive belt. Change the belt

(refer to REPLACING/REPAIRING the

Drive Belts in this section), and readjust

pulley travel as described by step 1 (above).

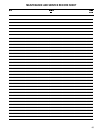

PTO Clutch Disengagement Adjustment

b. Check both the brake band and brake

drum on the drive pulley for wear. Replace

worn brake parts and readjust pulley travel

as described by step 1 (above).

Clutch Engagement/Belt Tension

The clutch engagement and PTO belt tension are

adjusted using the clutch actuator rod. Initially, after

installing a new PTO belt, after 10 hours and every

100 hours thereafter, check and adjust for the three

dimensions in the clutch linkage as shown.

Adjust the bolt head clearance [1/4 to 3/8 in. (6 to 10

mm)] first, then adjust spring length. If adjustments

are needed more frequently than 100 hours to main-

tain the linkage dimensions, it may suggest prob-

lems with pulley wear or belt misalignment.

WARNING

It is important to check and maintain

blade brake action for safe operation of

the machine.

Brake Band

Adjustment Nut

1/2 in.

(13 mm)

Clutch

Idler Pulley

Engine Pulley

PTO Drive

Pulley