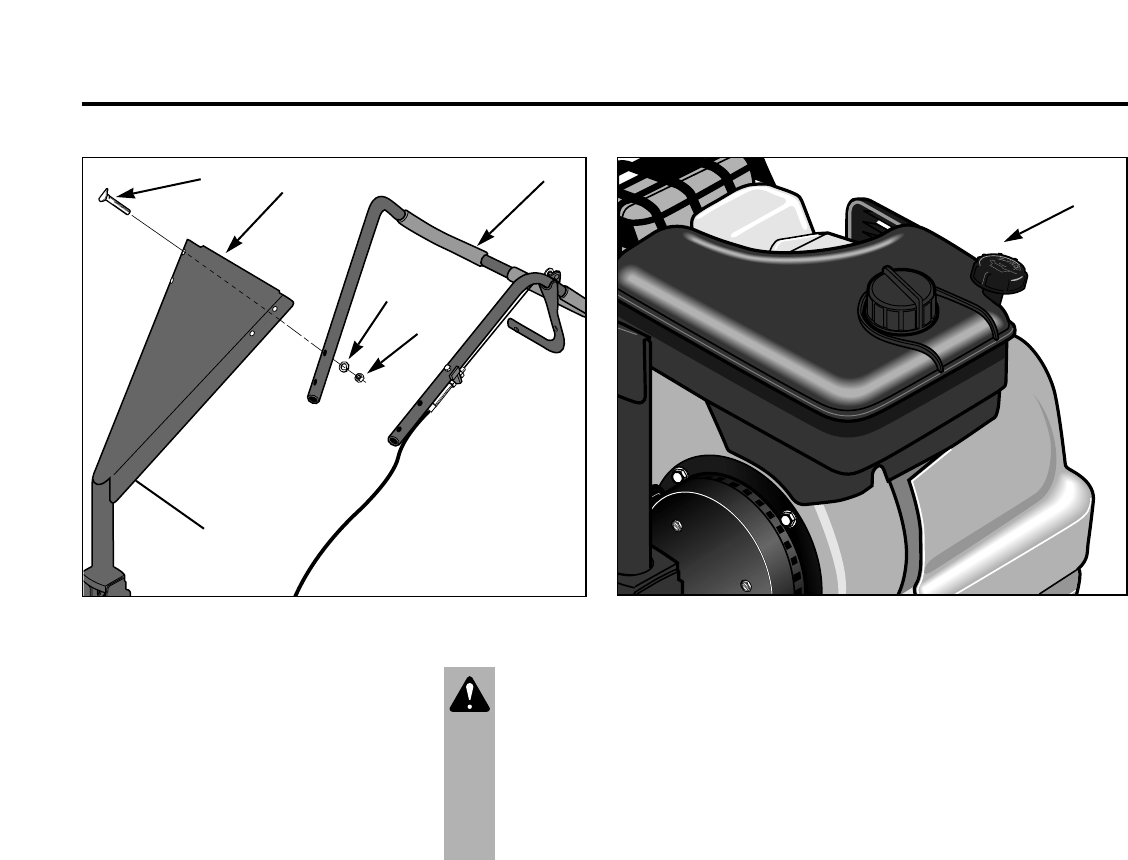

STEP 3: Attach Upper Handlebar

Section to Lower Handlebar Section

1. Align the mounting holes in the upper

handlebar section (F, Fig. 2-4) with the

corresponding mounting holes in the

lower handlebar section (G).

2. Insert four 5/16"-18 x 1-1/2" curved

head screws (H, Fig. 2-4) DOWN through

the holes in the two handlebar sections.

Install the top screws first for easiest

installation. Secure the screws with four

5/16" lockwashers (I), and four 5/16"-18

hex nuts (J). Tighten with a 1/2" wrench.

3. Press the handlebar control cable into

the plastic clip (K, Fig. 2-4) underneath

the left side of the control panel.

4. Lift up the handlebar locking lever and

swivel the handlebar toward the engine

starter rope to test hardware tightness at

the base of the handlebar. If the handlebar

seems secure and swivels smoothly, the

hardware is tightened properly. Tighten

the front bolt (D, Fig. 2-3) more if the

handlebar doesn’t seem secure enough.

Loosen the front bolt (D) a little if the

handlebar is hard to swivel. IMPORTANT:

This bolt must be tightened properly for

the handlebar to swivel properly. The

other long bolt next to it should not be

tightened now, but may at some time in

the future require tightening which is

explained in the Maintenance Section.

WARNING

DO NOT START THE ENGINE

UNTIL ENGINE CRANKCASE HAS

BEEN FILLED WITH OIL.

FAILURE TO FOLLOW THIS

INSTRUCTION WILL RESULT

IN SERIOUS ENGINE DAMAGE.

STEP 4: Add Motor Oil to Engine

1. Refer to the separate Engine Owner’s

Manual for the recommended type and

viscosity motor oil to use.

2. With the tiller on level ground,

unscrew and remove the oil fill dipstick

(L, Fig. 2-5). Using a funnel, pour fresh

motor oil into the dipstick opening. Add

oil gradually and check the level with the

dipstick several times to be sure not to

overfill the engine. Add oil until the level

is up to the “FULL” mark on the dipstick.

3. The oil level on the dipstick should

always be between the “ADD” and “FULL”

marks. Wait a few minutes after filling the

crankcase for the oil to settle. Re-check

the oil level and adjust as needed.

4. Wipe up any oil spillage and replace

the oil fill dipstick securely.

STEP 5: Check and Adjust

Tire Air Pressure

Use an automotive-type tire pressure

gauge to check the air pressure in both

pneumatic tires. Inflate both tires evenly

between 15-to-20 PSI.

STEP 6: Check External

Hardware for Tightness

Inspect the screws, bolts and nuts on the

tiller and make sure they are securely

tightened.

How To Move the

Machine in “Freewheel”

IMPORTANT: To “freewheel” (wheels

turn freely due to disengagement from

transmission gears) the machine off the

pallet to another location, unlock the

handlebar locking lever (see Pg. 9),

then swivel the lower section of the

handlebar (stand on the engine muffler

cage side only) 180

0

to position it over

the engine. Relock the lever. Using the

lower handlebar section for leverage,

roll the equipment to the desired

location. Swivel the handlebar back to

its original position over the tine hood to

return to the rear tine tiller mode. Do

not pick up the machine by the fenders

to avoid damage to the fenders.

8

Section 2: Assembly

Fig. 2-4

Fig. 2-5

F

G

H

I

J

K

L

Lower

Handlebar

Section

Upper

Handlebar

Section