7

WARNING

TO PREVENT PERSONAL INJURY

OR PROPERTY DAMAGE, DO

NOT START THE ENGINE UNTIL

ALL ASSEMBLY STEPS ARE

COMPLETE AND YOU HAVE READ

AND UNDERSTAND THE SAFETY

AND OPERATING INSTRUCTIONS

IN THIS MANUAL.

Inspect unit

Inspect the unit and carton for damage

immediately after delivery. Contact the

carrier (trucking company) if you find or

suspect damage. Inform them of the

damage and request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 days after the unit has

been delivered. Contact the factory if you

need assistance in this matter.

Tools/Materials Needed for

Assembly

(One) 1/2" wrench*

(Two) 9/16" wrenches*

(One) Automotive-type air pressure gauge

(One) Clean oil funnel

(One) Quart clean, high-quality engine oil.

Refer to the Engine Owner Manual

for engine oil specifications and

quantity required. Do not overfill.

* Adjustable wrenches may be

substituted.

IMPORTANT: Motor oil must be added to

the engine before starting. Follow the

instructions in this “Assembly” section

and in the Engine Owner’s Manual.

Unpacking Instructions

1. After opening the carton, remove card-

board support materials and packaging

material around handlebar and engine.

2. Lift up the carton to remove it.

3. Carefully put aside the upper section

of the handlebar (it is connected to the

machine by a control cable) and the hard-

ware bag. See Fig. 2-1. Do not kink the

control cable connected to the uper handle-

bar section. Also cut the plastic tie on the

handlebar to free the drive bail (Fig. 2-1).

4. The assembly is easiest by leaving the

tiller on the wood shipping pallet until the

handlebar has been completely assembled.

If the unit must be moved off the pallet

and rolled to another location for assem-

bly, see “Freewheel” message on Pg. 8.

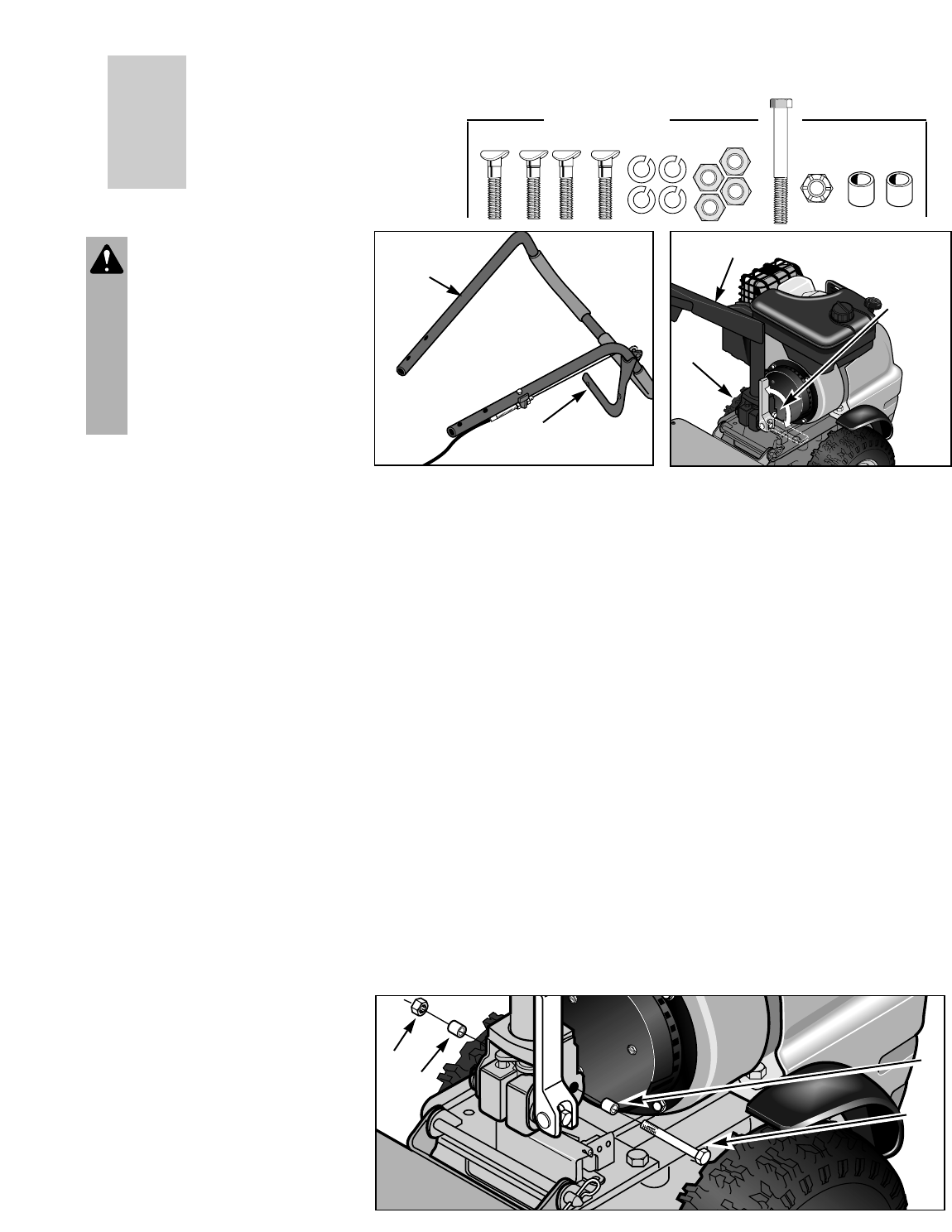

5. Open the hardware bag and group the

hardware. Check the contents against the

following list and Fig. 2-1A above (hard-

ware shown at a reduced size):

• four 5/16"-18 x 1-1/2" curved head screws

• four 5/16" lockwashers

• four 5/16"-18 hex nuts

• one 3/8"-16 x 3-1/4" screw

• one 3/8"-16 locknut

• two steel bushings (for handlebar)

STEP 1: Adjust Handlebar Height

1. Move the handlebar locking lever up

(A, Fig. 2-2), then tilt the lower handlebar

section upward to align the holes in the

base and the lower handlebar section (B).

2. Hold the lower handlebar section in

this position with the holes in the base

aligned. Move the handlebar locking

lever down to “freeze” the hole alignment.

STEP 2: Install Hardware in Base

and Lower Handlebar Section

1. Insert one bushing (C, Fig. 2-3) on the

end of the 3-1/4" long screw (D), and

slide the screw through the base of the

lower handlebar section. Put the other

bushing (C) on the screw on the other

side, sliding it on all the way.

2. Use 9/16" wrenches to install the 3/8"

locknut (E) on the screw (D). Tighten hard-

ware securely. NOTE: Do not tighten the

other long screw next to this hardware – it

is factory tightened. See Fig. 2-3.

Section

2

Assembly

Fig. 2-1

Fig. 2-2

Upper

Handlebar

Section

Cut plastic tie to

free the drive bail

Fig. 2-3: Install hardware to secure lower handlebar section to the base.

C

C

D

B

Hardware Shipped

Fig. 2-1A

A

Lower Handlebar

Section

E