22

Maintenance of the

Operational Interlock System

The Operational Interlock System is an

electrical safety system that prevents the

engine from starting (or shuts the engine

off) if either of two unsafe operating

conditions were to occur: 1) while in use

as a rear tine tiller with the handlebar

extending over the tine hood, the interlock

will shut the engine off if the tine hood

were not securely locked in place; 2)

while in use as a front tine tiller/cultivator

with the hood removed and the

handlebars positioned over the engine,

the interlock will shut the engine off if the

handlebar is swiveled more than 90

0

toward the exposed tines.

Keep the interlock switch area (M,

Fig.5-5) clean and free of all debris.

Inspect this location every time the

equipment is used and clean if dirty.

Also check the two electrical

connections (N and O, Fig. 5-6) on the

engine. The connectors must be securely

attached.

Section 5: Maintenance

Tine Maintenance

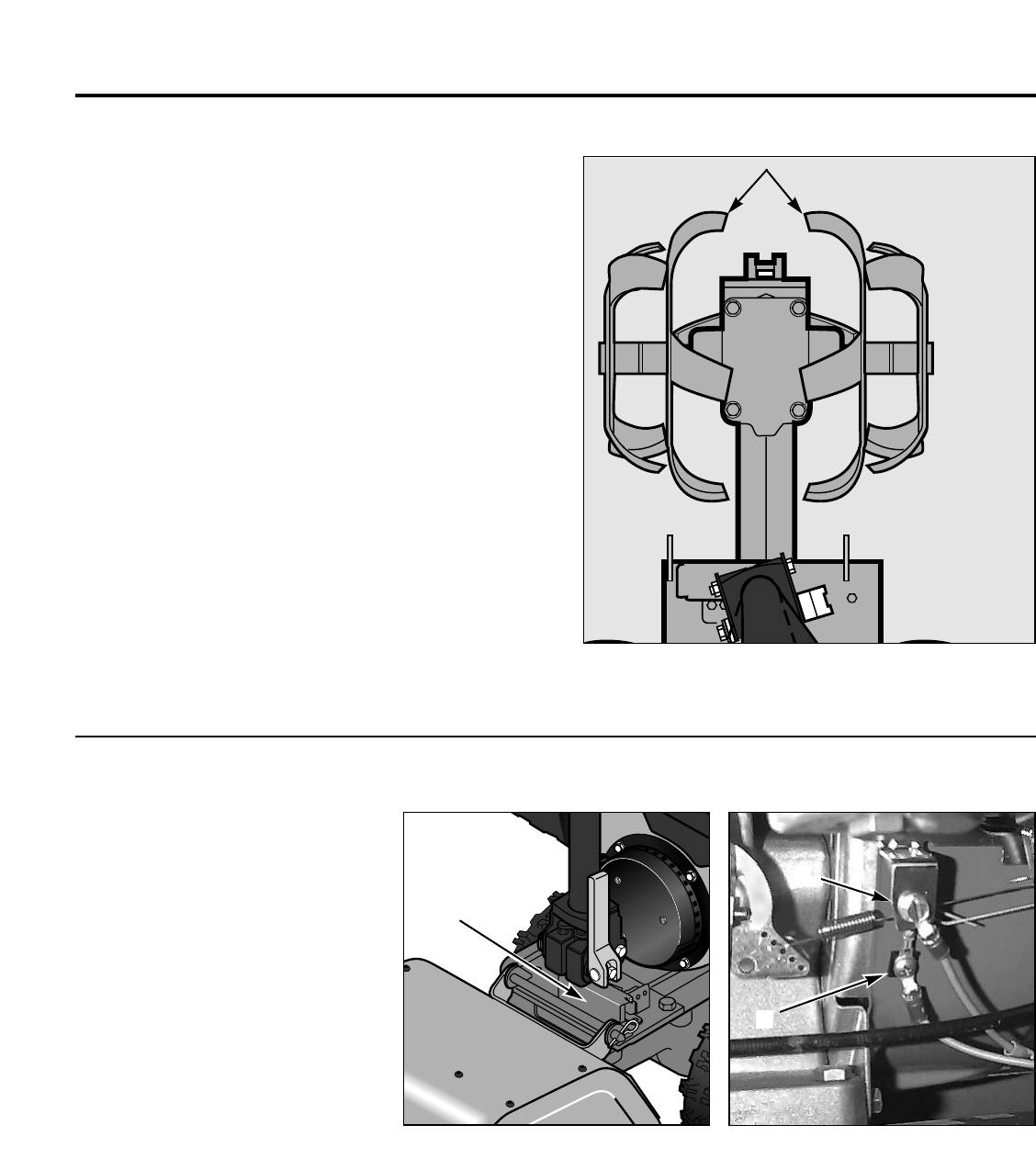

Tine Sets Should Be Inspected

Regularly and Replaced When Worn

Inspect the tines every 25 hours of

operation (or at least a couple of times a

year) for wear and general condition. If

any tines are broken, or if you notice that

tilling and cultivating do not mix the soil

as thoroughly as when the tines were

new, it’s time to inspect and perhaps

replace the tine sets. Refer to your parts

catalog for correct part number

information. NOTE: The tine sets with the

thicker tines must be positioned closest

to the transmission. The hardware

securing the tine sets must be tightened

securely (8 ft-lbs.).

The tine sets must be reinstalled as

shipped originally from the factory. The

tines are designed to rotate backward,

with their curved cutting edges entering

the soil first. If mounted incorrectly, the

tines may tend to run along on top of the

ground rather than digging in the soil.

This could unexpected-

ly cause the machine to

jump backward. Also–

the tines must all point

inward and the two tine

sets with the thicker

tines must be mounted

inboard, as seen in Fig.

5-4.

Fig. 5-4: All of the tines point inward. The tines are thicker on the two

inner sets. Tines must be mounted so each tine’s cutting edge enters

the soil first.

Fig. 5-5: Location of interlock switch.

Fig. 5-6: Engine shutoff locations.

M

N

O

THE TWO INNER TINE

SETS HAVE THICKER TINES

ALL TINES MUST

FACE INWARD AND

TINE CUTTING EDGES

MUST ENTER

SOIL FIRST