Traction Drive Systems

3 - 18 Two Stage Snowthrower Drive Systems Manual

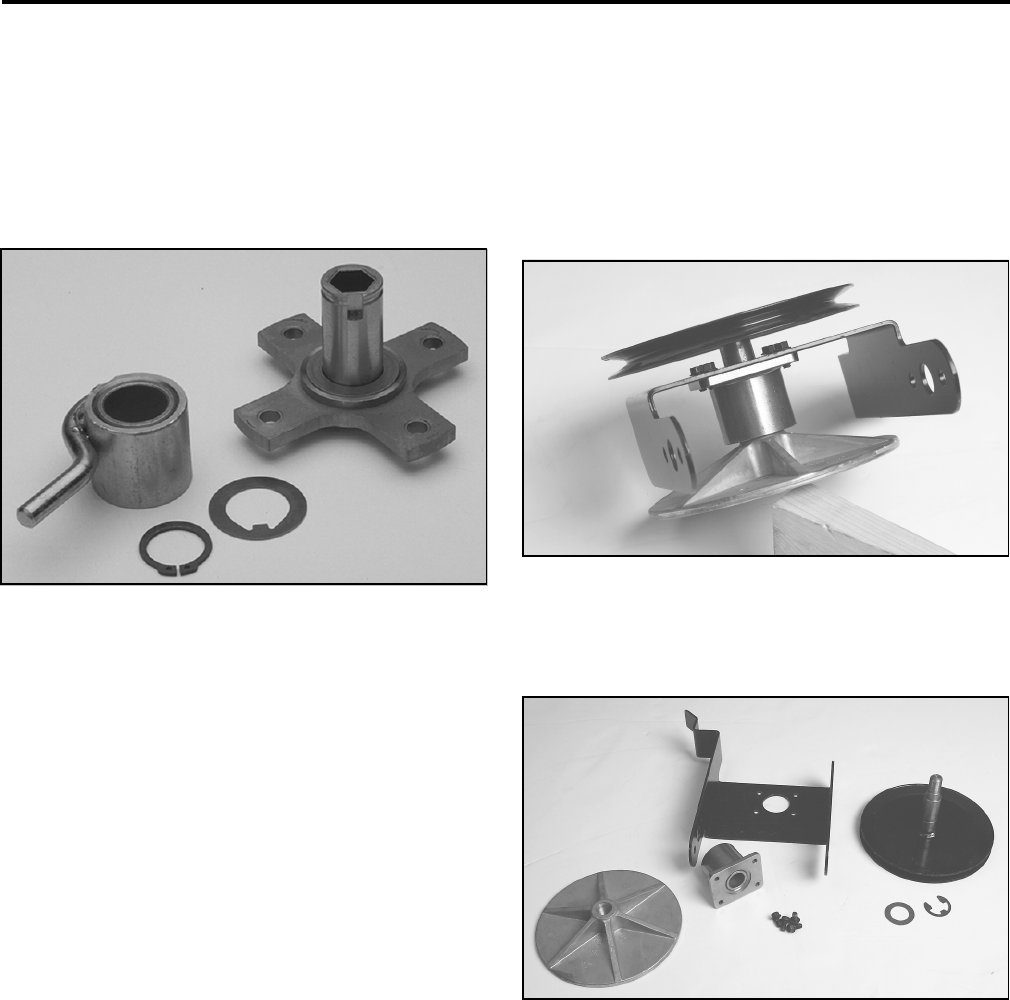

6. There are 2 versions of the hub and slider. The

early models use a normal thrust washer on either

side of the slider. Later models use a thrust

washer with an internal key that fits into a keyway

cut into the shaft portion of the hub. This keyed

version is current; if the older hub is ordered, you

will automatically get the new version (Figure

123).

Figure 123

0723-001

Assembly

1. Inspect the hex shaft for nicks, burrs, or rust.

Clean and deburr as necessary.

2. Coat the hex shaft with a light coat of engine oil,

just enough to prevent rust. Do not use grease as

it will stiffen in the cold and prevent shifting.

3. If you are reusing the old hub, assure it is clean

and free of burrs.

4. The slider contains an oil impregnated bearing.

Wipe the inside of the bearing with a clean shop

towel to assure there are no burrs or debris. Apply

2 or 3 drops of clean engine oil to the inside of the

bearing, install it on the shaft as shown

(Figure 122). Secure with the keyed thrust washer

and snap ring. Note the sharp edge of the snap

ring should face away from the slider.

5. Slide the spacer, sprocket, and key into place.

The shoulder on the sprocket should face away

from the slider. Apply a drop of Loctite™ Blue

#242 to the set screw and secure the sprocket to

the shaft.

Axle and Friction Plate Disassembly

1. The pulley and shaft go through the bearing hub

and the drive plate screws on. Note: The threads

are left hand. Rotate clockwise to remove the

plate. You may find it easier to clamp the drive

plate in a vise and unscrew the pulley (Figure

124).

Figure 124

1577-019

2. The pulley and shaft can now be drawn out of the

hub. Note the thrust bearing and snap ring

locations (Figure 125).

Figure 125

1577-023

3. Drive the 3 roll pins out of the axle. The axle will

now slide out of the bearings.

4. The bearings can now be removed from the

frame.

5. Remove 4 self-tapping screws that secure the hub

to the friction plate frame.