RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 33

MAINTENANCE/SERVICE

CAUTION

Observe all applicable safety precautions for the

solvent.

3) Remove the belt guard from the main frame.

Clean the inside of the belt guard with an

appropriate solvent. Check for signs of wear and

damage. Secure in a proper storage area.

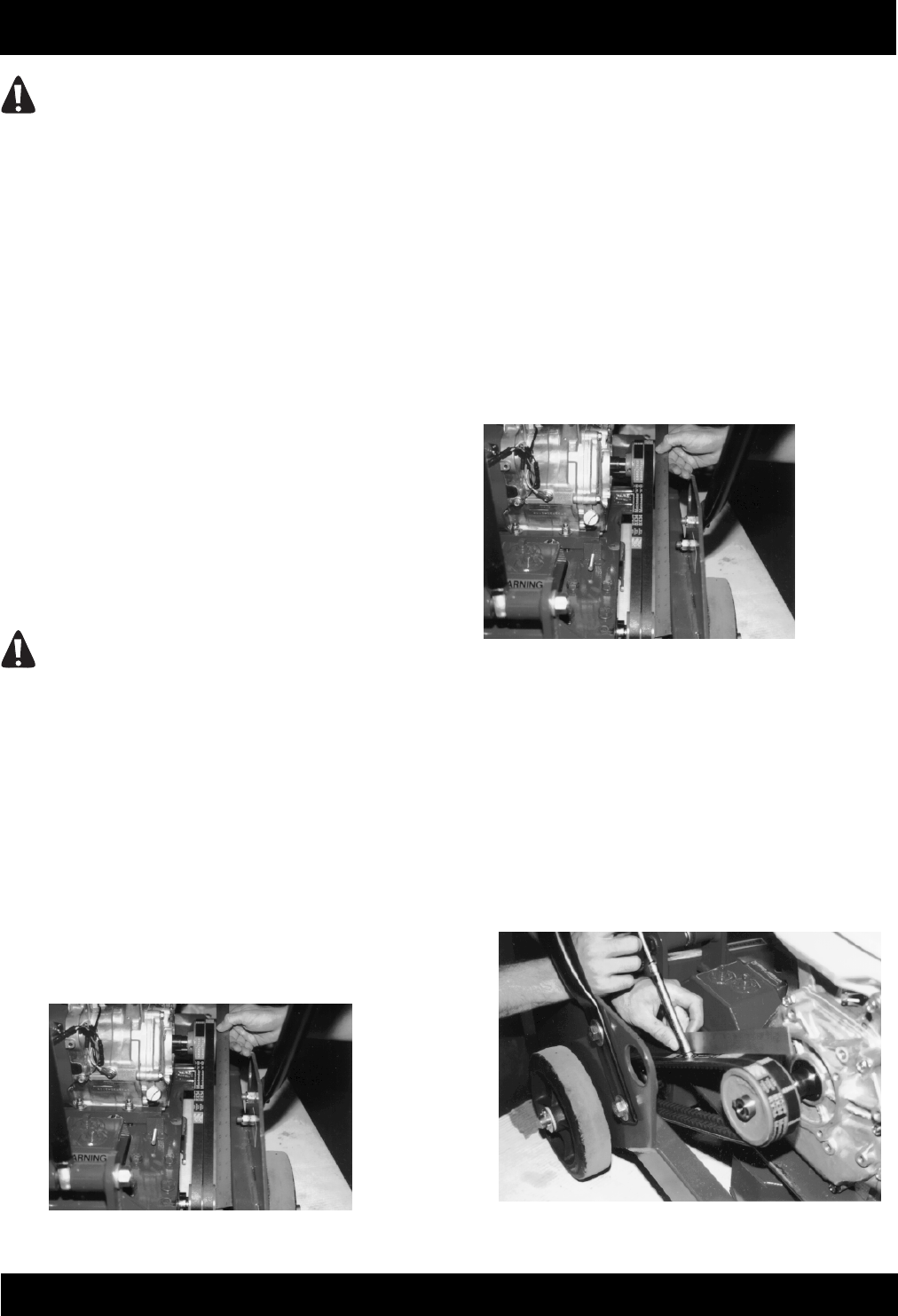

4) Using the 9/16 inch wrenches, loosen the

engine/motor mounting capscrews.

5) With the same wrenches, rotate the engine take-

up capscrews counterclockwise to loosen the V-

belts and allow the engine/electric motor to slide

toward the operator handle. FIGURE 37.

6) Remove the worn V-belts. Inspect the

engine/electric motor and arbor shaft pulleys for

wear and damage. Install the replacement belts, PN

BX34 in pairs. The Crack Saw utilizes two V-belts.

Always install replacement belts in matched pairs.

Never replace just one of the V-belts.

CAUTION

Do not operate the Crack Saw with only one V-

belt installed. One V-belt is not capable of

transmitting proper horsepower and torque

levels to the arbor shaft.

a) Do not install replacement belts if the pulleys

have excessively worn grooves. Such pulleys should

be replaced to insure proper belt fit. Operating the V-

belts in worn pulley grooves will accelerate wear,

reduce horsepower and torque levels and

significantly reduce component service life.

b) A V-belt should never be forced over a pulley.

More belts are broken from this cause than from

actual failure in service.

c) Keep the belts as clean and free of foreign

material as possible. Do not use belt dressing.

FIGURE 37

7) Tighten the engine/electric motor attachment

capscrews until they just begin to apply tension to

the engine/electric motor. DO NOT OVER

TIGHTEN. Alternately tighten the take-up capscrews

until slight tension is applied to the V-belt.

8) Belt alignment is checked with the straightedge.

Place the straightedge squarely against the arbor

shaft pulley. Properly aligned pulleys should also

place the straightedge squarely against the

engine/electric motor pulley. Remove the

straightedge and rotate the engine pulley 120

degrees. Recheck the alignment with the

straightedge. Repeat the process until the

engine/electric motor pulley has been rotated a full

360 degrees. Maximum allowable misalignment is +-

1/32 inch. FIGURE 38.

FIGURE 38

9) Apply increased belt tension by progressively

tightening the take-up capscrews against the

engine/electric motor.

a) Recheck V-belt alignment.

b) Check belt tension with the spring scale or belt

tension tool midway between the engine/electric

motor and arbor shaft pulleys. Belt deflection should

measure approximately .20 inch at 4 to 5-1/2

pounds force. FIGURE 39.

FIGURE 39