RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 20

ASSEMBLY INSTRUCTIONS/OPERATIONS

PROPER QUANTITY OF PERSONNEL IN

PROPER PHYSICAL CONDITION.

The integral lifting bail device(s) can be used to

facilitate lifting by a mechanical device incorporating

a chain and suitable attachment device. The location

of the lifting bail(s) may not always locate the exact

position of the center of gravity for the Crack Saw.

Typical Hoisting Configuration

FIGURE 7 depicts a typical hoisting configuration for

a Crack Saw with a mechanical lifting device.

FIGURE 10

DANGER

EXERCISE EXTREME CAUTION WHEN

UTILIZING A MECHANICAL DEVICE FOR

LIFTING THE CRACK SAW. UTILIZE THE

MECHANICAL DEVICE IN ACCORDANCE TO

BOTH ITS STATED STATIC AND DYNAMIC

LOADING ENVELOPES. DO NOT UTILIZE THE

MECHANICAL DEVICE UNTIL THIS

INFORMATION IS PROPERLY KNOWN AND

UNDERSTOOD BY ALL APPLICABLE

PERSONNEL. FAILURE TO PROPERLY UTILIZE

THE MECHANICAL DEVICE CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

8) Once on the job site, the Crack Saw can be

lowered to the work surface by reversing the above

steps.

General Transportation Information.

When transporting the Crack Saw on a motor

vehicle, the fuel tank breather vent (if so equipped)

must be completely closed to eliminate the

accidental seepage of fuel and resulting potential fire

and environmental hazards. To minimize the

possibility of damage to the Crack Saw, always

transport in its normal, upright position. All

equipment must be secured in/on vehicles with

suitable strapping or tie-downs. Personnel should

not be transported in the same compartment as

equipment and fuel supplies. Consult applicable

OSHA, AGA, CGA, etc. regulations for the proper

transportation of flammable gases.

STARTING THE RCC130H SERIES GASOLINE

POWERED CRACK SAW ON THE JOB SITE.

1) Position the Crack Saw on a flat and level surface

of firm foundation.

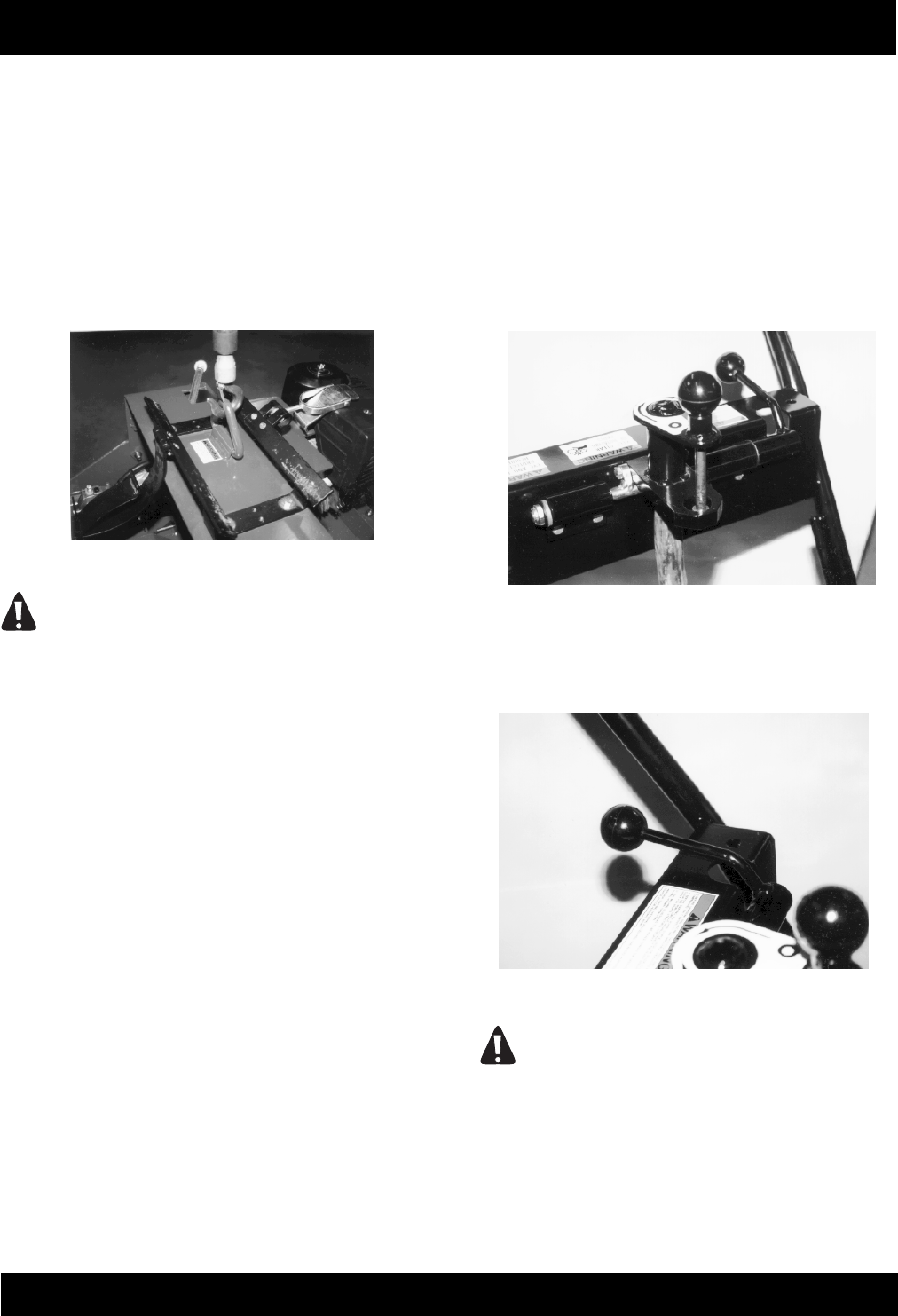

2) Rotate the height adjustment lever

counterclockwise to raise the blade to its maximum

position above the work surface. FIGURE 15.

FIGURE 15

3) Position the quick-change height lever over

center to its rear most (up) position. FIGURE 16.

FIGURE 16

DANGER

IMPROPER BLADE POSITION DURING THE

STARTING PROCEDURE CAN ALLOW THE

BLADE TO CONTACT THE WORK SURFACE

BEFORE THE OPERATOR CAN ASSUME A

PROPER OPERATING POSITION. THIS

OCCURRENCE CAN RESULT IN IMPROPER

DAMAGE AND/OR PERSONAL INJURY.