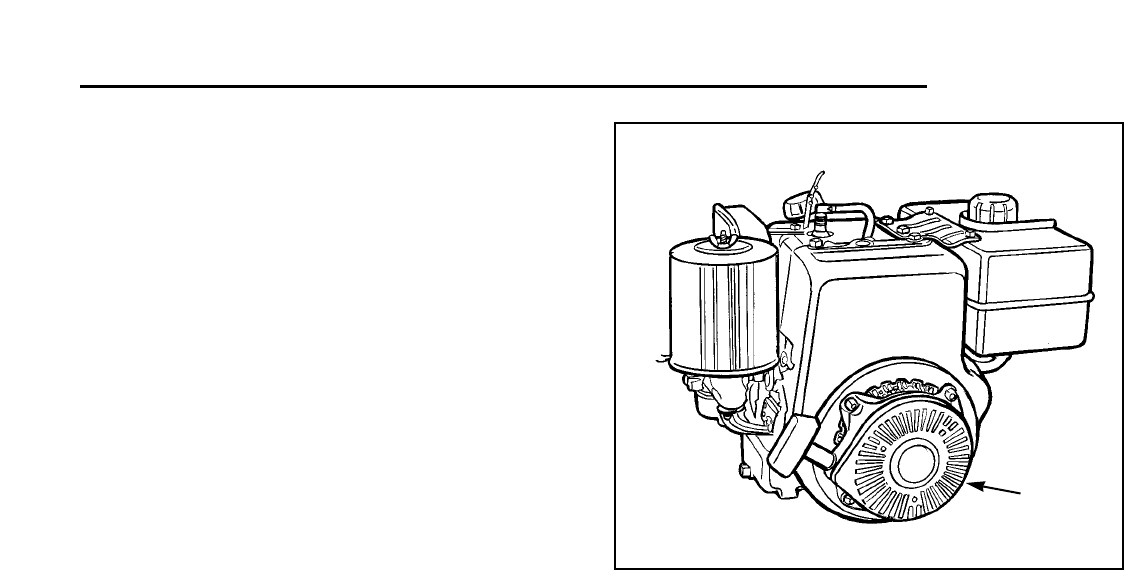

Clean Engine Fins/Air Intake Area

The engine that powers this chipper/shredder is air-

cooled, and requires unobstructed air flow into and

around the engine. For proper engine cooling, the cool-

ing fins on the engine cylinder head area must also be

kept clear of chipper/shredder deposits, as well as any

other build-up of debris that could prevent heat from radi-

ating away from the engine.

To clean the air intake area, remove any chipper/shred-

der build up, and then blow out the area using a stream

of compressed air. If a compressor is not available, use a

stiff bristle parts brush, which is available at most auto

parts supply stores.

To clean the cooling fins, brush the area between the

fins with a stiff bristle parts brush, and blow out any

remaining debris with a stream of compressed air. If the

cooling fins are caked with an oily build-up of

chipper/shredder debris, using a commercially available

engine cleaning aerosol may help loosen and remove

the deposits.

If you use such a cleaning product, you must follow all

safety and use instructions to prevent damage to the

engine components and personal injury to you.

Using a stream of water to clean the engine requires

immediate drying of engine components to prevent rust-

ing and possible malfunctioning of the engine’s electrical

system.

Clean/Oil/Replace Air Filter Element

The engine air filter element filters and removes airborne

dirt, dust, and other work site debris from the air before it

can enter the carburetor and damage sensitive fuel pas-

sages.

Depending on the type of air filter element installed on

your chipper/shredder engine, you should periodically

perform one of the following steps:

• clean and oil the air filter (foam filter only),

• only clean the air filter (Type “A” filter),

• or replace the filter every year or 100 hours of opera-

tion (paper filter element).

Consult the engine manufacturer’s manual provided with

your chipper/shredder for the specific instructions that

apply to your unit.

If you have any doubts about what type of filter element

you have, consult you local authorized dealer for help in

replacing or ordering the correct element.

17

Normal Care

*2569

Clean

Around

Area

Figure 13. Engine Air Intake Area

Inspect/Rotate Shredding Hammers

The patented shredding hammers on this line of chip-

per/shredders can be easily rotated to provide new cut-

ting surfaces as required.

Triangular hammers can be rotated twice, then flipped

over for a total of six sharp, new leading edges. “J” ham-

mers on the Model 5/14 can be flipped over once, for a

total of two sharp, new leading edges.

If the shredding action of the unit seems sluggish, or you

notice that shredded material is not shredded as thor-

oughly as when the unit was new, the shredding ham-

mers may need to be rotated or replaced.

Rotating the shredder hammers requires the following

major steps:

1. Removal of the shredder hopper.

2. Removal of the rotor housing.

3. Removal, rotation, and/or replacement of the shred-

der hammers.

4. Replacement of the rotor housing.

5. Replacement of the shredder hopper.

Consult the Troubleshooting and Repair Section of this

manual for complete disassembly, inspection, and

replacement instructions.

Your local authorized dealer can provide this service to

you if you do not wish to disassemble the unit and

inspect/repair it yourself.