19

General

The following information will help you make the neces-

sary checks and perform the procedures required to fol-

low the normal care recommendations made for your

chipper/shredder unit.

Your local authorized dealer can make these checks and

perform the required procedures for you.

CHECK FOR LOSE PARTS AND

HARDWARE

Check the following areas, and tighten as required:

1. Chipper Cone & Cone Mounting

2. Shredder Hopper

3. Rotor Housing

4. Deflector Shield

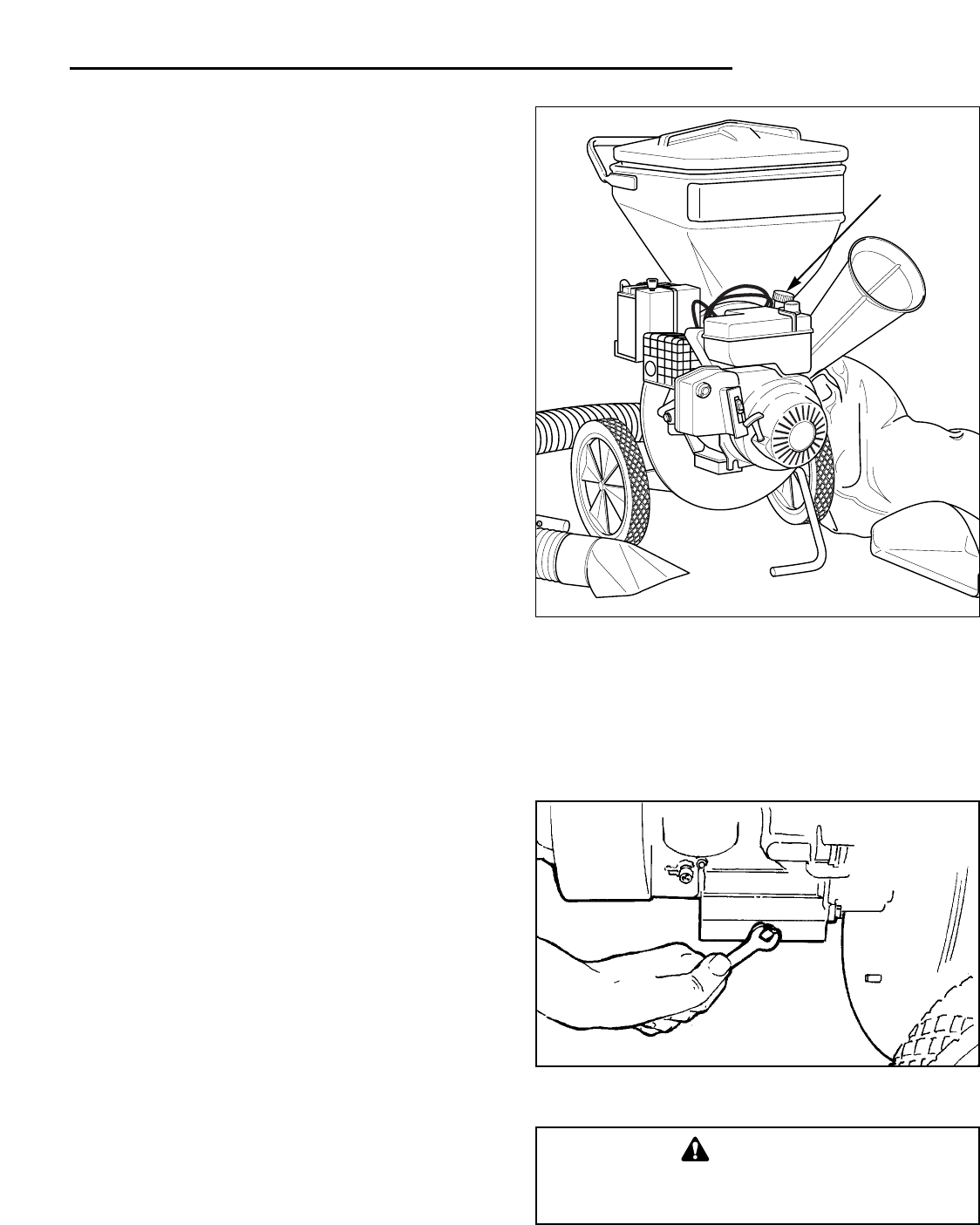

OIL LEVEL

1. Oil level must be full. Check the oil level by removing

and checking the engine dip-stick (Figure 15). The

oil level should be up to the full mark on the dip-stick.

2. Add the recommended oil a little at a time so as not

to overfill.

3. Do not overfill the engine oil! Excess oil can be detri-

mental to the engine.

4. After the proper oil level is reached, replace the dip-

stick and clean surrounding area of any spilled oil to

prevent the sticking of debris that could fall into

engine during the next oil check.

CHANGING OIL

Effective lubrication of the engine is critical to the life

expectancy of internal engine components. Because of

this, engine oil should be changed yearly when the chip-

per/shredder is used only occasionally, and more fre-

quently depending on the amount of time the

chipper/shredder is in use.

1. Drain engine oil by unscrewing drain plug (Figure 16)

in the engine base and letting oil drain into a suitable

container.

2. Dispose of the used oil by returning it to an oil recy-

cling center or service station with a oil recycling

tank.

3. After all old oil has been drained, screw drain plug in

securely, and add oil as instructed in the "Oil Level”

section, or see the engine manufacturer’s manual for

complete details and oil specifications.

CAUTION

Do not change the engine oil if the engine has

just been run. Hot oil causes burns.

*2556

Figure 16. Engine Oil Drain Plug

Regular Maintenance

Figure 15. Oil Dip Stick Location

Dip Stick

Located

Behind

Gas Tank