17

Saw Chain Performance

Using the appropriate round file, sharpen 1.

all cutters to a 25° angle as shown.

After all cutters are sharpened, use

2.

a depth gauge joiner to measure the

height of each depth gauge.

CHN-19

CHN-18

Using a ling

gauge

Using a depth

gauge joiner

Using a at le to

round the front

corner on a depth

gauge

25°

IMPORTANT!

File all cutters to the same angle and

depth! Unequal filing may cause the saw

to vibrate or cut erratically!

NOTE:

For consistent ling angles, use a ling

guide.

IMPORTANT!

Most of the actual cutting is done by the

sides and corners of the individual cutters!

Your saw’s performance on the job

depends heavily on the condition of its

saw chain.

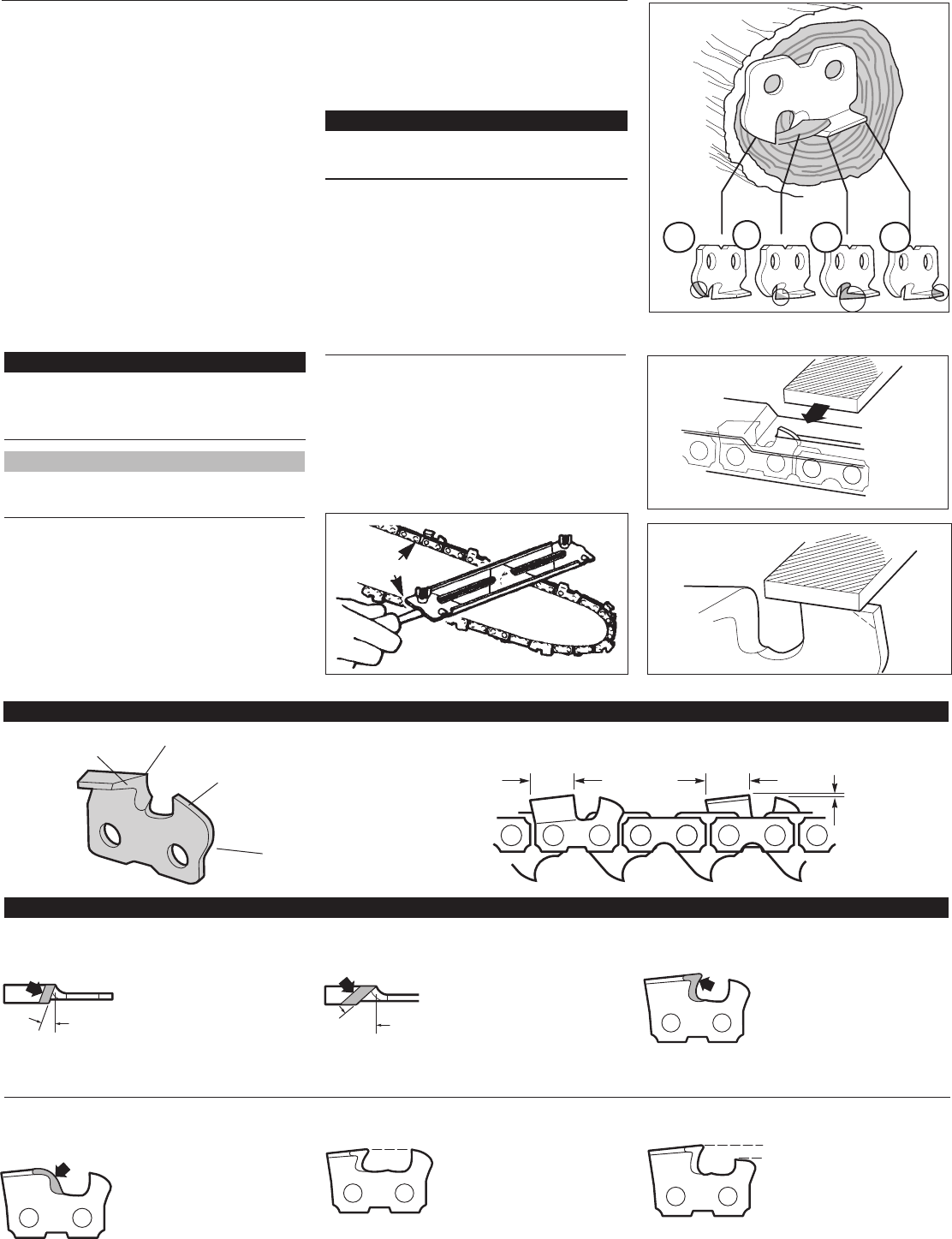

How the Saw Chain Works

As the saw chain is pulled through the wood:

The depth gauge setting determines 1.

the depth of cut for each cutter.

The cutter’s leading edge enters the

2.

wood, causing the entire cutter to “rock

back” and lift away from the bar.

CHN-09

1

2

3

4

Sharpening Technique

The top plate peels the severed wood 3.

chip away.

The chip is discharged out the rear of

4.

the cutter.

As required, use a flat file to lower

3.

depth gauges to the appropriate .025”

(0.64 mm) height.

After all depth gauges have been

4.

adjusted, use a flat file to round each

depth gauge leading edge to original

curvature and angle.

50°

CS_top plate angle greater than

originally titled CHN-07

20°

CS_top plate angle less than

CHN-05

CHN-04

CHN-03

CHN-02

A BA=B

0.025"

CHN-01

Correct Filing Technique

Filing Problems

Top plate

angle less than

recommended

Backslope on

side plate cut-

ting edge

Top plate angle

more than

recommended

Hook in side

plate cutting

edge

Cause

File held at less than recom-

mended angle.

Result

Slow cutting. Requires extra

effort to cut.

Remedy

File cutters to recommended

angle.

Cause

File held too low or the le

was too small.

Result

Rough cutting. Chain grabs.

Cutters dull quickly or won’t

hold a cutting edge.

Remedy

Check le size. File cutters to

recommended angle.

Cause

File held too high or the le

was too large.

Result

Cutters won’t feed into wood.

Slow cutting. Must force chain

to cut. Causes excessive bot-

tom wear.

Remedy

File cutters at recommended

angle. Check le size.

Cause

File held at more than recom-

mended angle.

Result

Cutting angle is very sharp but

will dull fast. Cutting action

rough and erratic.

Remedy

File cutters to recommended

angle.

Low depth

gauge

High depth

gauge

Cause

Wrong gauge setting or no

gauge used.

Result

Rough cutting. Chain grabs.

Saw won’t pull chain through

wood. Excessive wear on the

cutter heel.

Remedy

If depth gauges are too

low, the chain is no longer

serviceable.

Cause

Depth gauge never led.

Result

Slow cutting. Must force chain

to cut. Will cause excessive

wear on the cutter heel.

Remedy

Lower gauges to recommend-

ed setting.

0.025” (0.64 mm)

CHN-08

Correct angle

on top plate

Slightly protruding hook or point

(curve on non-chisel chain)

Top of depth gauge at correct

height below top plate

Front of depth

gauge rounded

Keep all cutter lengths equal!