16

40/50 Hour Maintenance

Spark plug: replace the spark plug ■

with an NGK BPMR7A (or equivalent),

gapped to 0.024” (0.6 mm).

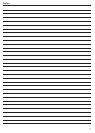

Fuel filter: use a hooked wire to

■

extract the fuel filter from inside the

fuel tank, and then remove and replace

the filter element. Before replacing the

filter, inspect the condition of the fuel

line. If damage or deterioration are

noted, the saw must be removed from

service until it can be inspected by a

Shindaiwa-trained service technician.

CAUTION!

Make sure you do not pierce the

fuel line with the end of the hooked

wire. The line is delicate and can be

damaged easily.

Fuel Line

Fuel Filter

Hooked

Wire

Oil filter: extract the oil filter from ■

inside the oil tank, and then wash the

filter element in an approved solvent.

If damage or deterioration are noted

on the oil suction line, the saw must

be removed from service until it can

be inspected by a Shindaiwa-trained

service technician.

(over 30 days)

Thoroughly clean the saw exterior. ■

Remove all chips and other debris from

the cylinder fins and cooling passages.

Drain the fuel tank, and then clear the ■

carburetor and lines by running the

saw until it stops from lack of fuel.

Drain any remaining bar oil from the

■

oil reservoir.

CAUTION!

Never store the saw with any fuel

remaining in the tank, fuel lines, or

carburetor! Your Shindaiwa warranty

does not include coverage for damage

caused by “stale” or contaminated fuels!

Long Term Storage

Remove, clean, and reinstall the air fil- ■

ter element as described under “Daily

Maintenance.”

Repair or replace any damaged compo-

■

nents as required, and then store the

unit in a clean, dry, dust-free area.

Protect the chain by using a chain ■

cover.

Remove the spark plug, and then pour ■

1/4 ounces (5 ml) of 2-cycle mixing

oil into the cylinder through the spark

plug hole. Before reinstalling the spark

plug, slowly pull the recoil starter 2-3

times to distribute the oil over the cyl-

inder walls.

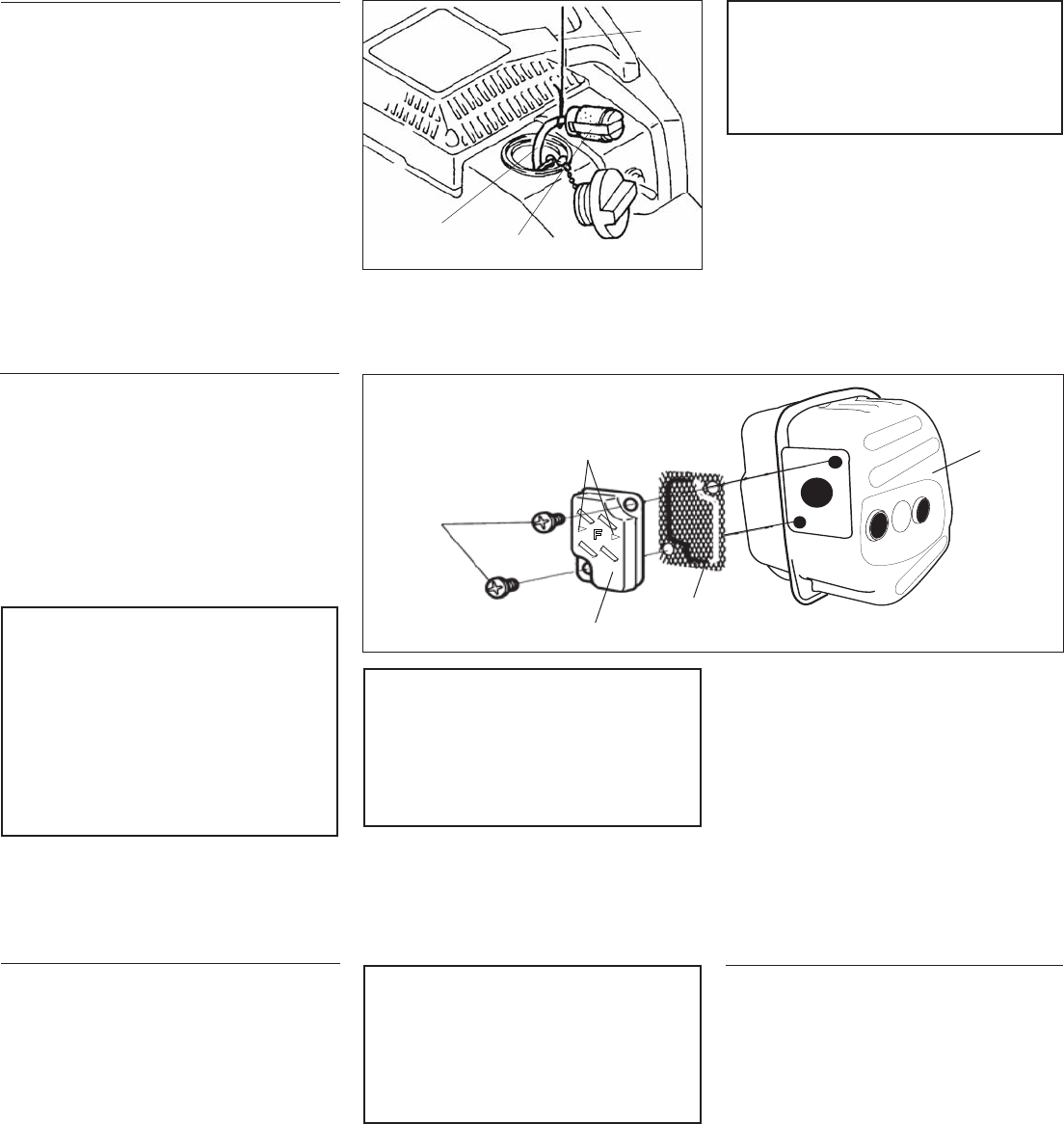

Hard starting or a gradual loss of perfor-

mance can be caused by carbon deposits

lodged in the muffler’s spark arrester screen.

To service or replace the spark arrester,

remove the two cover screws and cover, then

remove the screen. Clean the screen with a

small wire brush. Replace if damaged. Rein-

stall the screen and cover with the arrows

directed to the front of the muffler.

Spark Arrester Maintenance

CAUTION!

Carbon deposits in the combustion

chamber or exhaust port cannot

be removed in the eld. For decar-

bon- ization, return the unit to your

Shindaiwa dealer.

CAUTION!

When installing the spark arrester

cover make sure the arrows are

directed to the front of the mufer. If

the spark arrester cover is installed

incorrectly, the hot exhaust gases

will be directed into the chain saw

and may cause heat damage to sur-

rounding parts.

Cover

Screws

Direction

Arrows

Cover

Front of

Mufer

Arrester

Screen

Maintenance (continued)