15

Remove dirt and debris from the saw exte- ■

rior, cylinder fins, and cooling air intake.

Inspect the saw for fuel and oil leaks. ■

Repair as necessary.

Service the air filter:

■

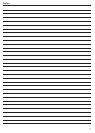

Remove the air filter cover and then 1.

remove the element. Use extreme care

to prevent any debris from entering the

carburetor bore. Wash all parts with

soap and water, and then gently wipe

or blow dry before reassembly.

Install the air filter element in the saw.2.

Cover

Filter Element

Choke

Sharpen and adjust the saw chains as ■

required.

Clean the guide bar groove and oil

■

hole, and inspect the bar groove and

tip for damage or unusual wear. Repair

or replace worn or damaged compo-

nents as necessary.

Inspect the drive sprocket.

■

Inspect the entire saw for damaged, ■

loose or missing components or fas-

tenings. Repair as necessary.

10/15 Hour Maintenance

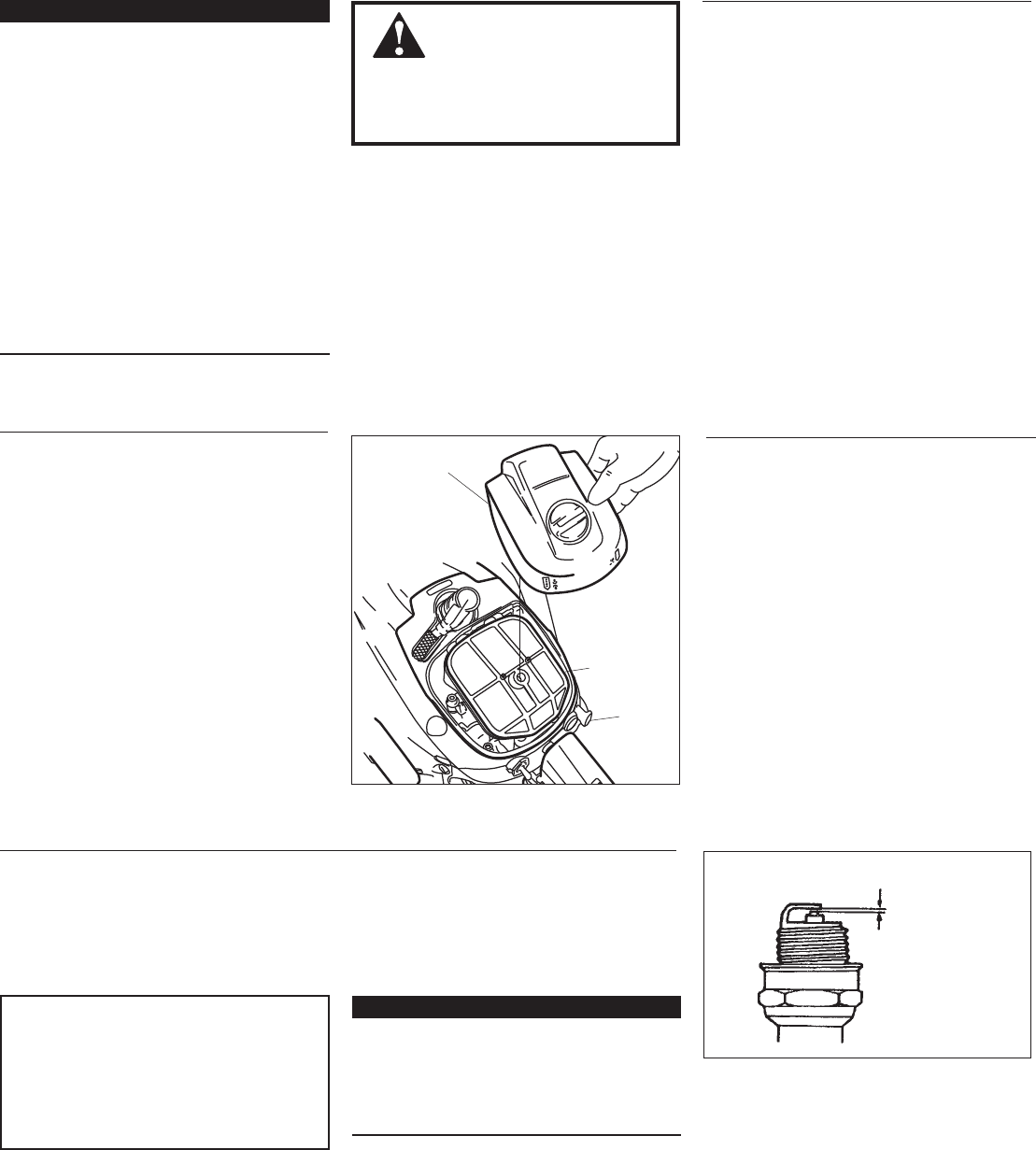

Remove and clean the spark plug. ■

Adjust the spark plug gap to 0.024”

(0.6 mm), and reinstall. Replace any

damaged or visibly worn plug with an

NGK BPMR7A or equivalent spark

plug of the same heat range.

CAUTION!

Never allow chips or other debris

to enter the cylinder bore! Before

removing the spark plug, thoroughly

clean the spark plug and cylinder

head area!

0.024” (0.6

mm)

IMPORTANT!

The drive sprocket and saw chain loop

should always be replaced as a set! For econ-

omy, rotate the same 2-3 chains daily. When

these chains are worn out, replace both the

chains and drive sprocket at the same time.

Remove the guide bar and chain. Care- ■

fully inspect the drive sprocket for

wear or damage, and replace if noted.

Inspect the guide bar grooves and

tip for wear or damage, and repair or

replace components as required.

Daily Maintenance

WARNING!

Before performing any

maintenance on this saw, stop the

engine and disconnect the spark

plug wire!

IMPORTANT!

MAINTENANCE, REPLACEMENT

OR REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE PER-

FORMED BY ANY REPAIR ESTABLISH-

MENT OR INDIVIDUAL; HOWEVER, WAR-

RANTY REPAIRS MUST BE PERFORMED

BY A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA CORPO-

RATION. THE USE OF PARTS THAT ARE

NOT EQUIVALENT IN PERFORMANCE

AND DURABILITY TO AUTHORIZED

PARTS MAY IMPAIR THE EFFECTIVE-

NESS OF THE EMISSION CONTROL SYS-

TEM AND MAY HAVE A BEARING ON

THE OUTCOME OF A WARRANTY CLAIM.

Maintenance

Mufer

This unit must never be operated with

a faulty or missing spark arrester or

muffler. Make sure the muffler is well

secured and in good condition. A worn or

damaged muffler is a fire hazard and may

also cause hearing loss.

Spark Plug

Keep the spark plug and wire connec-

tions tight and clean.

Fasteners

Make sure nuts, bolts, and screws

(except carburetor adjusting screws)

are tight.