33

LUBRICATION AND MAINTENANCE

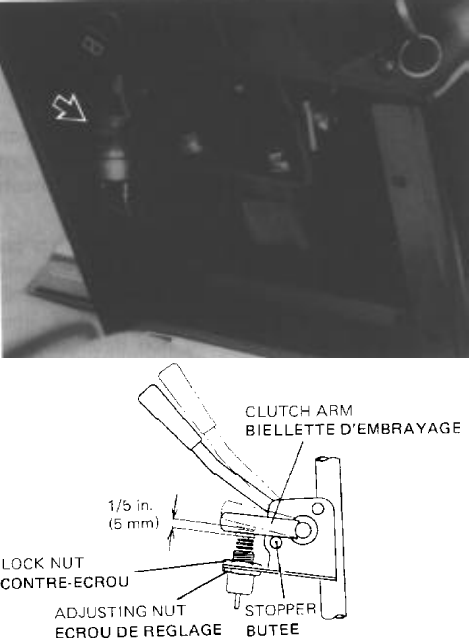

PTO SAFETY SWITCH ADJUSTMENT

If the engine will not start because the PTO safety

switch requires adjustment, adjust the switch as

follows:

1. Stop the engine and remove the starter key.

2. Remove the access panel.

3. Move the PTO clutch lever slightly toward the

“ON” position. This will release the switch

knob from the PTO clutch arm, Figure 52.

4. The safety switch knob is retracted by pulling

the PTO clutch lever to the “OFF” position.

Loosen the locknut, Figure 52. The safety

switch should be adjusted by screwing the

adjusting nut out or in so that the knob may

retract 1/5 in. (5mm) when the PTO clutch

lever is moved from the “ON” to the “OFF”

position.

5. After adjusting the switch be sure that it works

properly and tighten the locknut. If the clutch

lever does not move freely, lubricate the

clutch lever wires.

Figure 52 P.T.O. Safety Switch Adjustment

NOTE: When the engine cannot be started even if

the adjustments of brake pedal safety switch and/or

PTO safety switch have been made, con consult

with your RANSOMES Dealer.

TRACTOR STORAGE

Tractors that are to be stored for an extended period

should be protected during storage. The following is

a suggested list of operations to be carried out.

1. Thoroughly clean the tractor. Use touch-up

paint where necessary to prevent rust.

2. Check the tractor for worn or damaged parts.

Install new parts as required.

3 Lower the equipment hydraulically so the lift

piston 5 in a fully retracted position. This will

protect the piston surface from corrosion and

rust.

4. Lubricate the tractor. Drain and refill the

transmission, hydraulic system and rear axle

with new oil. Drain the engine oil and refill with

new lubricating oil. Also clean the air cleaner.

5. Remove the battery and clean it thoroughly.

Be sure that it is fully charged, and that the

electrolyte is at the proper level. Place it in

storage in a cool, dry place above freezing

temperature. The battery should be charged

periodically during storage.

6. Place blocking under the tractor axles.

7. Use the following storage procedure.

l Before storing, the fuel system should be

flushed with a special oil, a quantity of which

will remain in the system when the engine is

shut down for storage.

l Special diesel fuel system flushing oils are

available from most oil companies. If special

flushing oil is not readily obtainable, mix 0.24

litres of SAE 1 0 non-detergent engine oil 4.73

litres of No.2 diesel fuel.

l Drain the fuel tank and pour two U.S. gallons

7.57 litres of the special flushing oil (or

lubricating mixture) in the fuel tank.