17

MAINTENANCE

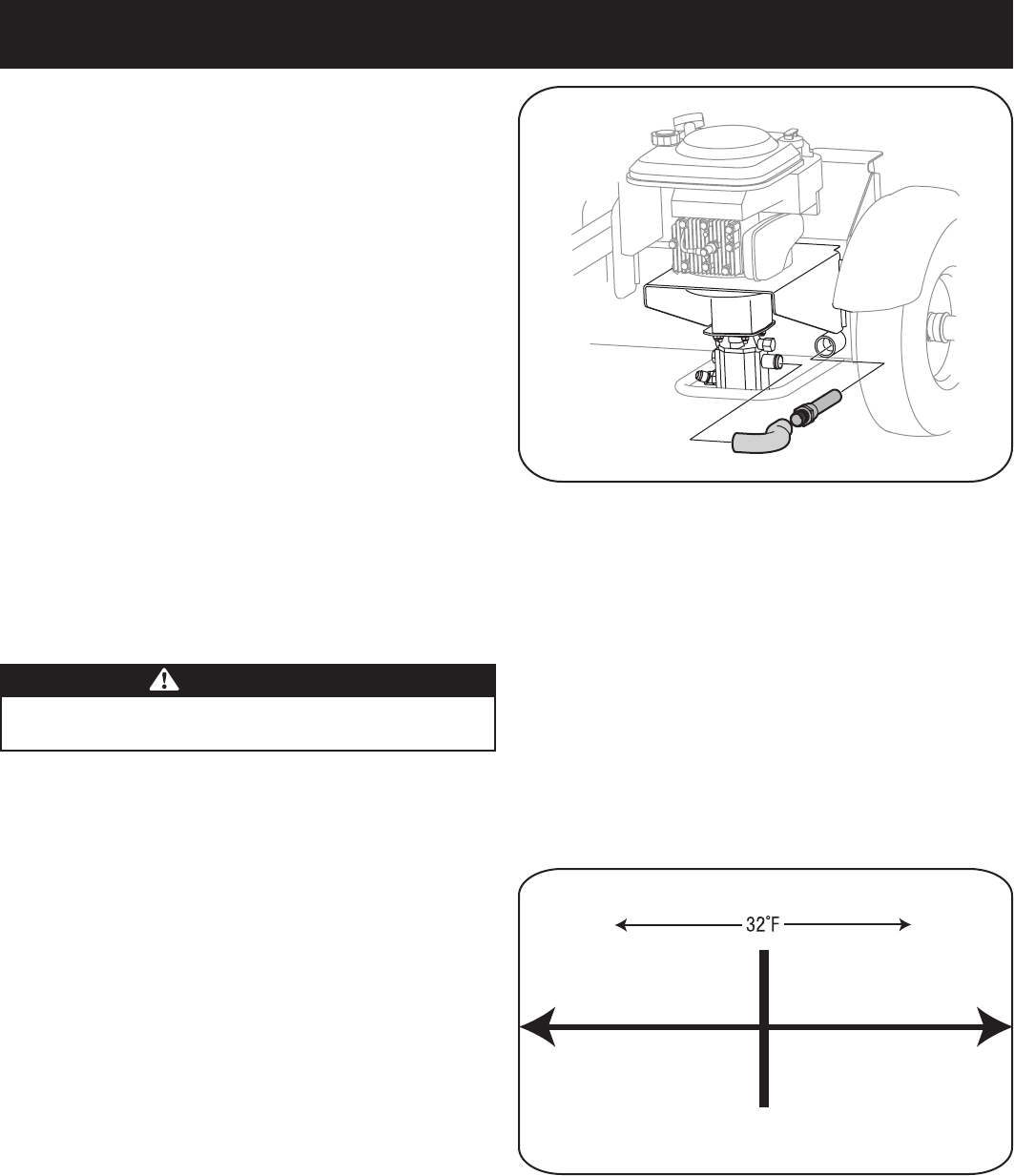

Figure 5-2

HYDRAULIC FLUID AND INLET FILTER

• Checkthehydraulicfluidlevelinthelogsplitterreservoirtank

before each use. Maintain the fluid level within the range specified

on the dipstick at all times.

• Changethehydraulicfluidinthereservoirevery100hoursof

operation. Follow the steps below:

1. Disconnect the suction hose from the bottom of the reservoir tank.

2. Carefully unthread the inlet filter and clean it with penetrating oil.

See Figure 5-2.

3. Allow the fluid to drain into a suitable container.

4. Reinsert the filter and refill the reservoir with three (3) gallons of oil.

ApprovedfluidsincludeDexron®III/Mercon®automatictransmis-

sion fluid or a 10 Weight AW hydraulic oil.

• Maintainthefluidlevelwithintherangespecifiedonthedipstickat

all times.

NOTE: Always dispose of used hydraulic fluid and engine oil at

approved recycling centers only.

• Contaminantsinfluidmaydamagethehydrauliccomponents.

Flushing the reservoir tank and hoses with kerosene whenever

service is performed on the tank, hydraulic pump or valve is

recommended. Any repair to the hydraulic components should be

performed by a Sears Service Center.

WARNING

Us e e x t r e m e c a U t i o n w h e n w o r k i n g w i t h k e r o s e n e . it is a n e x t r e m e ly

f l a m ma b le f l U i d .

Hydraulic Filter

• Changethehydraulicfilterevery50hoursofoperation.Useonlya

10 micron hydraulic filter. Order part number 723-0405.

BEAM AND SPLITTING WEDGE

• Beforeeachuse,lubricatebothsidesofthebeam(whereitcomes

into contact with the splitting wedge) with engine oil. The wedge

plate on the log splitter is designed so the gibs on the side of the

wedge plate can be removed and rotated and/or turned over for

even wear.

• Makecertaintoreadjusttheadjustmentboltssothewedgemoves

freely,butnoexcessspaceexistsbetweenthewedgeplateandthe

beam.

ENGINE

Check Engine Oil

1. Stop the engine and wait several minutes before checking the oil

level.

2. Remove the oil fill dipstick.

3. Check the oil level on the dipstick. With the engine on level ground,

the oil must be to the FULL mark on the dipstick.

4. Replace the dipstick and tighten.

Changing Engine Oil

Only use high quality detergent oil rated with API service classification

SF, SG, or SH. Select the oil’s SAE viscosity grade according to the

expectedoperatingtemperature.Followthechartbelow:

Colder

5W30

SAE 30

Oil Viscosity Chart

Warmer