Service Engine - Page 28

SERVICE ENGINE

2. Disconnect spark plug wires (A) and remove spark

plugs.

3. Clean spark plugs carefully with a wire brush.

4. Inspect plug for:

• Cracked porcelain.

• Pitted or damaged electrodes.

• Other wear or damage.

5. Replace spark plug(s) if necessary.

6. Check plug gap with a wire feeler gauge, gap should be

0.76 mm (0.030 in.)

7. To change gap, move the outer electrode.

8. Install and tighten spark plugs. Tighten plugs to 24.4 to

29.8N•m(18to22lb-ft).

9. Connect the spark plug wire(s).

10.Lower hood.

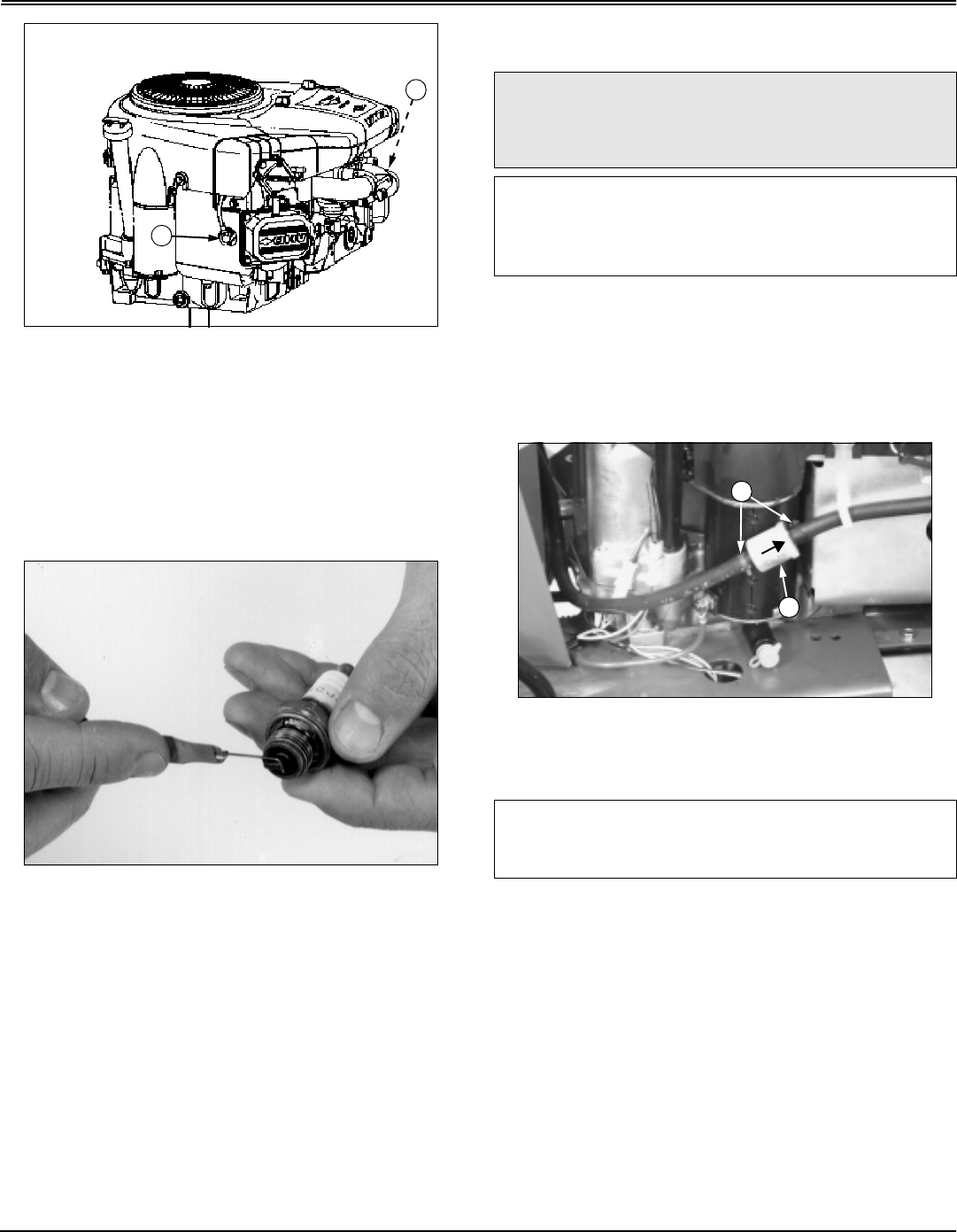

Replacing Fuel Filter

NOTE: Change filter when fuel is low in fuel tank.

1. Park tractor on a level surface.

2. STOP engine. LOCK park brake. Remove key. Let

engine COOL.

3. Lift hood.

4. Using pliers, slide hose clamps (A) away from fuel filter

(B).

5. Disconnect hoses from filter.

6. Position new filter with FLOW ARROW pointing in the

direction of fuel flow and connect hoses.

7. Install clamps and check for leaks.

8. Lower hood.

A

A

c CAUTION: Avoid injury. Keep cigarettes,

sparks, and flames away from the fuel system.

Make sure engine is cool to the touch.

IMPORTANT: Avoid machine damage. When

disconnecting fuel tank hose from filter, be sure to

hold hose above fuel tank level so fuel does not run

out.

IMPORTANT: Avoid machine damage. Filter must

be installed with FLOW ARROW pointing in the

directionoffuelflow.

A

B