50

■ MUFFLER

• Inspect periodically, the muffler for loose fasteners,

any damage or corrosion. If any sign of exhaust

leakage is found, stop using the machine and have it

repaired immediately.

• Note that failing to do so may result in the

engine catching on fire.

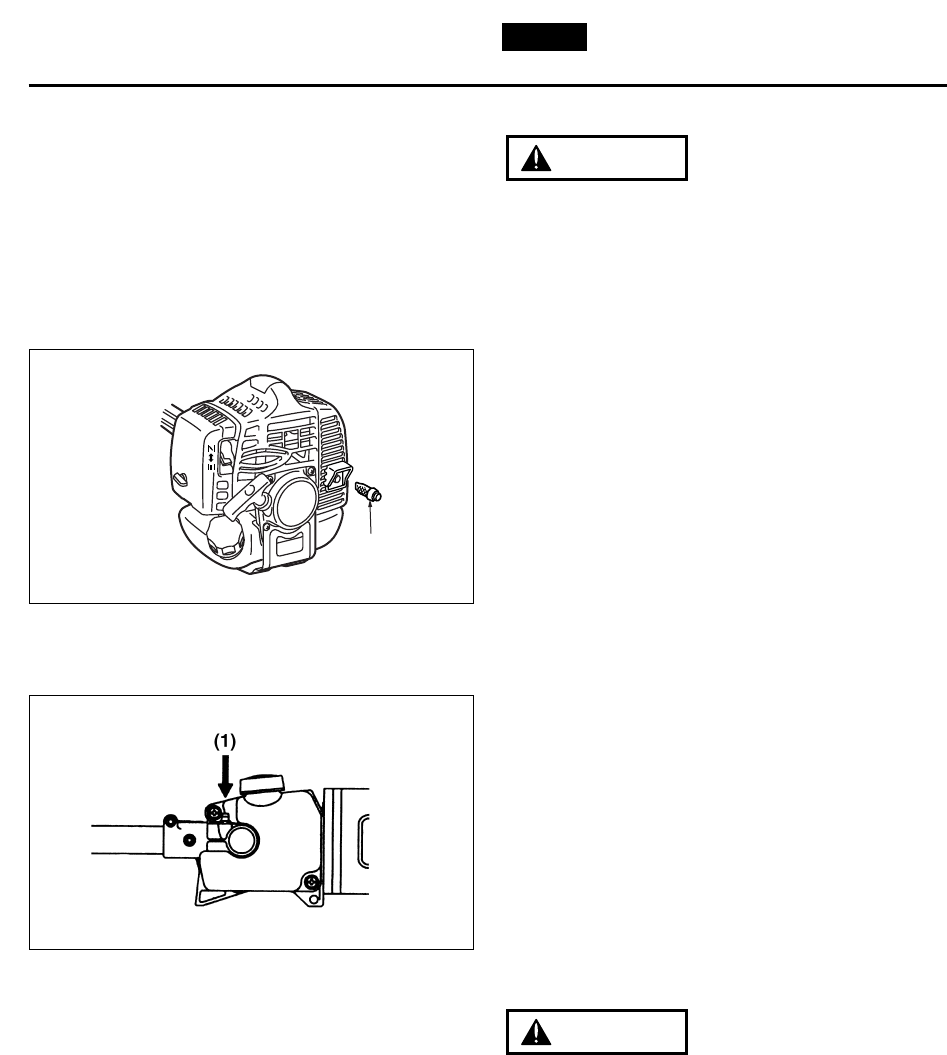

■ SPARK ARRESTER (MA12)

• The muffler is equipped with a spark arrester to

prevent red hot carbon from flying out of the exhaust

outlet. Periodically inspect and clean as necessary

with a wire brush.

In the State of California it is required by law

(Section 4442 of the California Public Resources

Code) to equip a spark arrester when a gas powered

tool is used in any forest covered, brush covered, or

grass covered unimproved land. (MA5)

(1) Spark arrester

■ GEAR CASE (MA13)

The reduction gears are lubricated by multipurpose,

lithium-based grease in the gearcase.

Supply new grease every 25 hours of use or more

often depending on the job condition.

When adding lubricant, use a grease gun to insert

lubricant into the three grease nipples located on the

gear case. (MA9)

(1) Grease fitting

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or spark plugs

with your bare hands immediately after stopping

the engine. The engine can become very hot

when in operation, and doing so could result in

severe burns.

•When checking the machine to make sure that it

is okay before using it, check the area around

the muffler and remove any wood chips or

leaves which have attached themselves to the

brushcutter. Failing to do so could cause the

muffler to become overheated, and that this in

turn could cause the engine to catch on fire.

Always make sure that the muffler is clean and

WARNING

WARNING

(1)

MA12

MA13

9. Maintenance

English