20

GAS CONNECTIONS

The heater requires a gas supply of not less than

4" (10.2cm) wc and not more than 14" (35.6cm) wc.

Gas supply pressures outside of this range may result in

improper burner operation. A minimum flowing or

dynamic inlet pressure of 4" (10.2cm) wc is required to

maintain input rating. The gas supply must be installed in

accordance with the National Fuel Gas Code, ANSI

Z223.1, or standard CSA B149.1, Natural Gas and

Propane Installation Codes, as applicable and all applica-

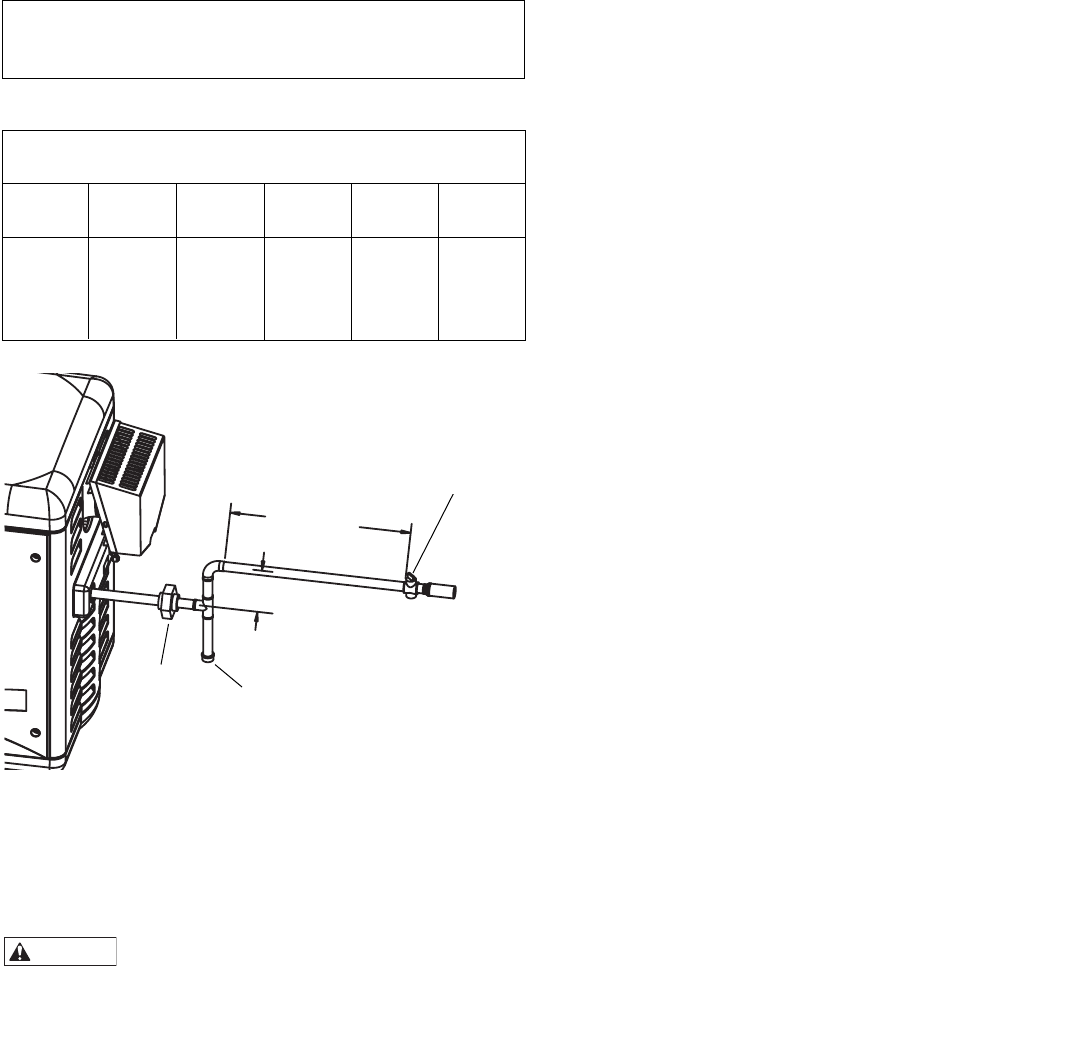

ble local codes. Install a manual shut-off valve and a sed-

iment trap and union located outside the heater panels

(Figure 21). Do not use a restrictive gas cock.

The following minimum gas pipe sizes are recommended

for natural gas supply piping. For low pressure LP gas,

pipe size may be reduced by 1/4", with a minimum pipe

size of 3/4". Check for compliance with local codes.

NOTICE: DO NOT use a corrugated flexible gas line to

supply the heater. it will not deliver enough gas (at

nominal diameter) to supply heater.

PRESSURE TESTING

Before operating the heater, the heater and its gas con-

nections must be leak tested. Test all gas connections for

leaks with soapy water.

Risk of fire or explosion. Do not use an open

flame to test for leaks. The heater and its individual shut-

off valve must be disconnected from the gas supply pip-

ing system during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.5 kPa).

The heater must be isolated from the gas supply system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply at test pressures equal

to or less than 1/2 psig (3.5 kPa).

SUPPLYING POWER TO THE HEATER

The heater requires a 120V or 240V/60Hz/1Ph power

supply. Enclose the line to the heater in an approved

flexible conduit connected directly to the junction box on

the inside of the access door panel.

Line voltage field wiring should be 14 gauge, with a cir-

cuit capacity of 15 amps.

ELECTRICAL WIRING

NOTICE: Before making any electrical connections to the

power supply, remove the access door panels, open the

control box, remove the 12-pin plugs from their bag, and

plug in the correct plug (120 volt or 240 volt). Note that

installing the 120V plug and then connecting the heater

to 240V line current will immediately destroy the trans-

former, control board and ignition control module, and

will void warranty. If you install the 240V plug and con-

nect the heater to 120 volts line current, the heater will

not operate. Please read the boxes headed “IMPORTANT!

READ ME FIRST!” on pages 23 and 27 before proceed-

ing.

1. All wiring must be in accordance with all applicable

codes.

2. The heater, when installed, must be electrically

grounded and bonded in accordance with local codes

or, in the absence of local codes, with the National

Electrical Code or the Canadian Electrical Code (as

applicable). A bonding lug is provided on the outside

of the panel under the vent for this purpose.

3. Electrical power circuits to the pool heater must fol-

low local codes and National Electrical Code or

Canadian Electrical Code (as applicable).

4. All wiring between the heater and devices not

attached to it, or between separate devices which are

installed in the field, must be Type T wire rated for

35°C rise.

5. All line voltage wiring shall be enclosed in approved

flexible conduit, and shall be securely attached to the

field wiring box located inside the access door panel.

The conduit or cable connector at the field wiring box

should contain an insulating bushing or its equivalent

to prevent abrasion of the wires as they enter the

box.

6. The filter pump should run continuously when

the heater is on, and for at least 15 minutes

after the heater turns off. Any switches in the

pump circuit (including circuit breakers) that

can disconnect the pump must also disconnect

the heater.

7. Do not wire single pole switches, including protective

devices, into a grounded line. The heater is not sen-

sitive to polarity.

WARNING

GAS LINE

18"-24" of 3/4"

AT LEAST 4"

Recommended Pipe Size For Natural Gas

1,000 BTU/ft

3

, 0.6 Sp Gr, 0.5" wc Pressure Drop

0-25’ 26-50’ 51-100’ 101-200’ 201-300’

Model (0-7.6M) (7.6-15M) (15-31M) (31-62M) (62-92M)

200 3/4 in. 1 in. 1 in. 1-1/4 in. 1-1/4 in.

250 3/4 in. 1 in. 1-1/4 in. 1-1/4 in. 1-1/4 in.

300 1 in. 1-1/4 in. 1-1/4 in. 1-1/2 in. 1-1/2 in.

400 1 in. 1-1/4 in. 1-1/4 in. 1-1/2 in. 2 in.

FIGURE 21: Gas line and Trap

Table 10

Sediment trap

Union

Manual

shut-off

valve