PAGE 54 — DCA-60SSI2 — PARTS AND OPERATION MANUAL — REV. #3 (09/15/01)

DCA-60SSIU — MAINTENANCE

Figure 58. Valve Adjustment

Valve Clearance Check

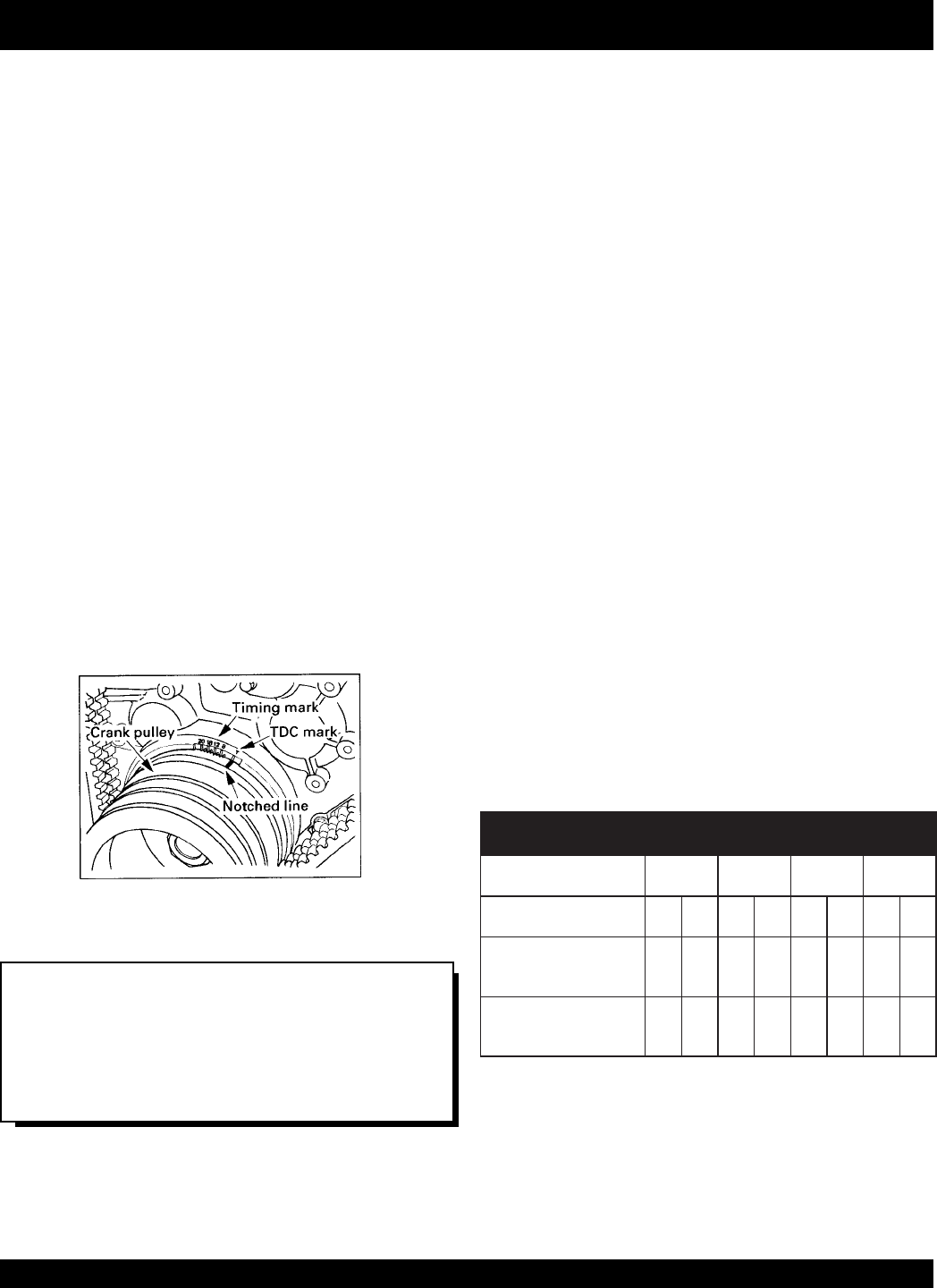

1. In order to bring No. 1 or No. 4 cylinder to top dead center

in the compression stroke, align the notched line on the

crank pulley with TDC mark on the timing gear case

cover.

2. Do the adjustment on the circle marked valves in the

below table where No. 1 cylinder is at the center in the

compression stroke.

3. After adjustment started from either piston top center,

turn the crankshaft 360

o

to align the notched line with

the TDC mark to do the adjustment again on the

remaining valve. See Table 16 and Figure 55 for valve

arrangement.

Injection Timing Check and Adjustment

1. Bring No. cylinder to the top dead center on the

compression stroke.

2. Turn the crankshaft pulley clockwise (viewed at engine

front) and align the notched line on the crank pulley with

the TDC mark on the timing gear case cover.

3. Remove the timing check hole cover at the front of

injection pump to check the alignment between the

pointer “a” on the injection pump gear lock plate and the

projected area mark “b” on the timing gear case.

4. If “a” and “b” are in alignment, the timing is set correctly.

If not, follow nos. 1-3 until the “a” and “b” are aligned.

5. Reversely turn the crankshaft pulley counterclockwise

viewed at the engine front about 30

o

crank angle.

6. Remove No. 1 injection pipe from the engine.

7. Remove the injection pump No. 1 delivery valve holder,

delivery valve and spring and reinstall the delivery valve

holder on the original place.

8. Delivery valve holder tightening torque:

39~44Nm(29~33lbft.)

9. Slowly turn the crankshaft pulley clockwise and at the

same time continue to feed the fuel with pumping the

Feed pump. When the fuel stop to flow out from No. 1

delivery valve holder, stop pumping.

10. Observe and make sure which mark (injection starting

angle line) on the timing gear case cover is aligning with

the notched line on the crank pulley.

11. The timing line shows the injection starting crank angle

of the engine.

12. The injection starting crank angle should be at the 14

o

timing mark.

tnemtsudAevlaV.51elbaT

)tsuahxE=E;telnI=I(

.oNrednilyC1234

tnemegnarrAevlaV IEIEIEIE

pottasi1.oNnehW

ehtniretnecdaed

ekotsnoisserpmoc

XXX X

pottasi4.oNnehW

ehtniretnecdaed

ekortsnoisserpmoc

OO OO

NOTE:

Take necessary precautions to prevent dust and

foreign particles in the pump interior when timing

adjustments are made.