14 15

MAINTENANCE

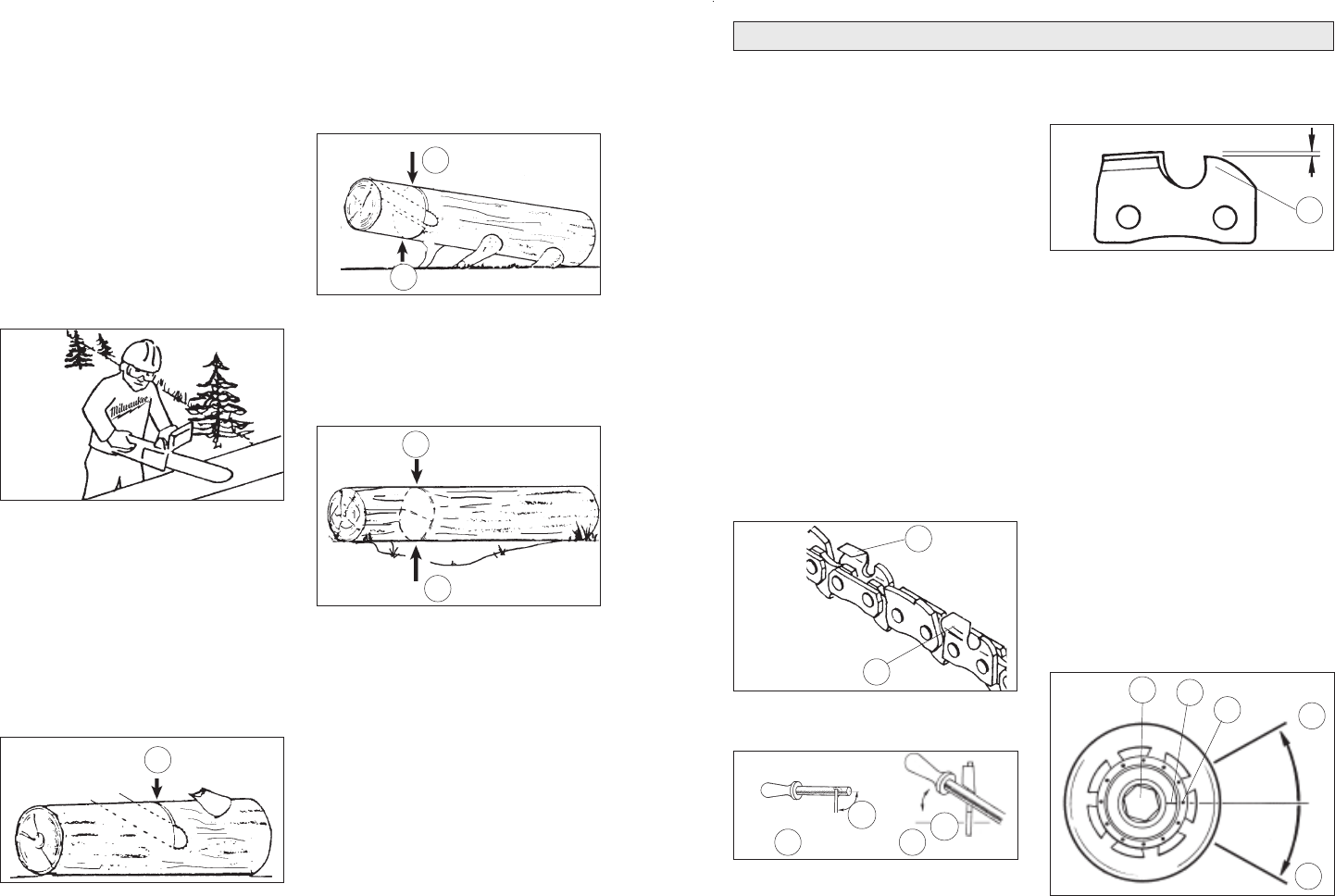

Bucking a log

When bucking a log, (cutting it into lengths)

it is important to make sure your footing is

firm and your weight is evenly distributed.

In general, try to have the log raised and

supported near the cut. Having the log

raised and supported near the cut will re-

duce binding and kickback.

If bucking log on hill (Fig. 27)

The operator should be on the uphill side

of the cut so when the cut off piece rolls,

it rolls away from the operator. Do not let

the chain come into contact with the

ground. Toward the end of the cut reduce

cutting pressure, maintain firm grip, and be

prepared for log to roll away from the saw

and the operator.

Fig. 27

Fig. 28

A

If log supported on one end (Fig. 29)

If log supported on one end cut 1/3 of the

way through the log from the bottom (A)

and finish the cut from the top (B). Cutting

this way will make the cut off portion fall

away cleanly and easily.

If log supported along entire length

(Fig. 28)

If log supported along entire length, such

as on the ground, cut from the top (A) roll

log over and finish the cut. Rolling the log

over and finishing the cut from the top will

prevent the cutting into the ground where

the dirt and stones will dull the chain.

Fig. 29

B

A

Fig. 30

B

A

If log supported on both ends (Fig. 30)

If log supported on both ends cut 1/3 of the

way through the log from the top (A) and

finish the cut from the bottom (B). Use ex-

tra caution to make sure that the chain saw

does not bind up in the cut.

After completing the cut, wait for the saw

chain to stop before moving the saw. Al-

ways stop the motor before continuing to

another tree.

Setting the Depth (Fig. 33)

The front part (A) of the cutter link is de-

signed to limit the depth of cut of the tooth.

Fig. 33

A

If the tooth is limited too much, the chain

saw will not cut as effectively as it

can.

If the tooth is not limited enough, the

tooth will take too big a bite and contrib-

ute to kickback.

File the front of the cutter link so that it is

.025" lower than the cutting tooth.

The Clutch (Fig. 34)

This chain saw is equipped with a disc

clutch designed to protect the motor from

overload. It has been preset at the factory.

The clutch should slip when the saw is

bogged down in a cut. If the clutch slips

during a normal cut, or does not slip when

the saw is bogged down in a cut, adjust it

as follows.

1. Engage the brake.

2. Remove the sprocket cover.

3. Note the stamped mark on the flange

(B).

Under normal usage, your chain saw will

require regular inspection and maintenance.

Examine the saw for dirt and debris that

might prevent safety and anti-kickback de-

vices from working properly. Inspect the

saw and its safety devices to determine

that it will operate properly. Failure to fol-

low the maintenance procedures indicated

below or the removal of safety devices

may increase the risk of injury.

Cleaning guide bar, chain and chain

brake

Remove the guide bar and chain after each

use or as needed to clean out chips and

debris from the sprocket area. Clean guide

bar groove, soak in light oil and wipe clean.

Clean out chips and debris from the chain

brake after each use or as needed. Check

the brake for normal operation before each

use. See "Cleaning" for further cleaning

instructions.

Sharpening chain (Fig. 31 & 32)

Use a 5/32" diameter round file to sharpen

cutter links (A).

Fig. B shows the link from the front.

Fig. C shows the link from the top.

Fig. 31

A

A

B

90°

30°

C

Fig. 32

Fig. 34

B

A

E

D

C

Replacing the chain

To replace the chain, refer to instructions

under Assembly. Use only Low-Kickback

saw chains that meet the ANSI B175.1-

2000 kickback requirements, other chains

may not reduce kickback. Refer to your

MILWAUKEE catalog for proper replace-

ment parts.

4. Rotate the adjusting bolt flange (A) so

that the mark on the flange (B) lines up

with the next reference mark on the

thrust washer (C).

If the clutch is slipping during a normal

cut, tighten the adjusting bolt flange to

the next mark clockwise (E).