6 7

CHAIN SAW TERMINOLOGY

Grounded tools require a three wire ex-

tension cord. Double insulated tools can

use either a two or three wire extension

cord. As the distance from the supply out-

let increases, you must use a heavier

gauge extension cord. Using extension

cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer

to the table shown to determine the re-

quired minimum wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For

example, a 14 gauge cord can carry a

higher current than a 16 gauge cord. When

using more than one extension cord to make

up the total length, be sure each cord con-

tains at least the minimum wire size re-

quired. If you are using one extension cord

for more than one tool, add the nameplate

amperes and use the sum to determine the

required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord out-

doors, be sure it is marked with the

suffix W-A (W in Canada) to indi-

cate that it is acceptable for outdoor

use.

Be sure your extension cord is prop-

erly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualified person before using it.

Protect your extension cords from

sharp objects, excessive heat and

damp or wet areas.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

Recommended Minimum Wire

Gauge for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to

five volts at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

Bucking

The process of cross cutting a felled tree

or log into lengths.

Chain Brake

A device used to stop the chain saw.

Chain Saw Powerhead

A chain saw without the saw chain and

guide bar.

Clutch

A mechanism for connecting and discon-

necting a driven member to and from a ro-

tating source of power.

Drive Sprocket or Sprocket

The toothed part that drives the saw chain.

Felling

The process of cutting down a tree.

Felling Back Cut

The final cut in a tree felling operation made

on the opposite side of the tree from the

notching undercut.

Front Handle

The support handle located at or toward

the front of the chain saw.

Front Handle Guard

A structural barrier between the front

handle of a chain saw and the guide bar,

typically located close to the hand position

on the front handle and sometimes em-

ployed as an activating lever for a chain

brake.

Guide Bar

A solid railed structure that supports and

guides the saw chain.

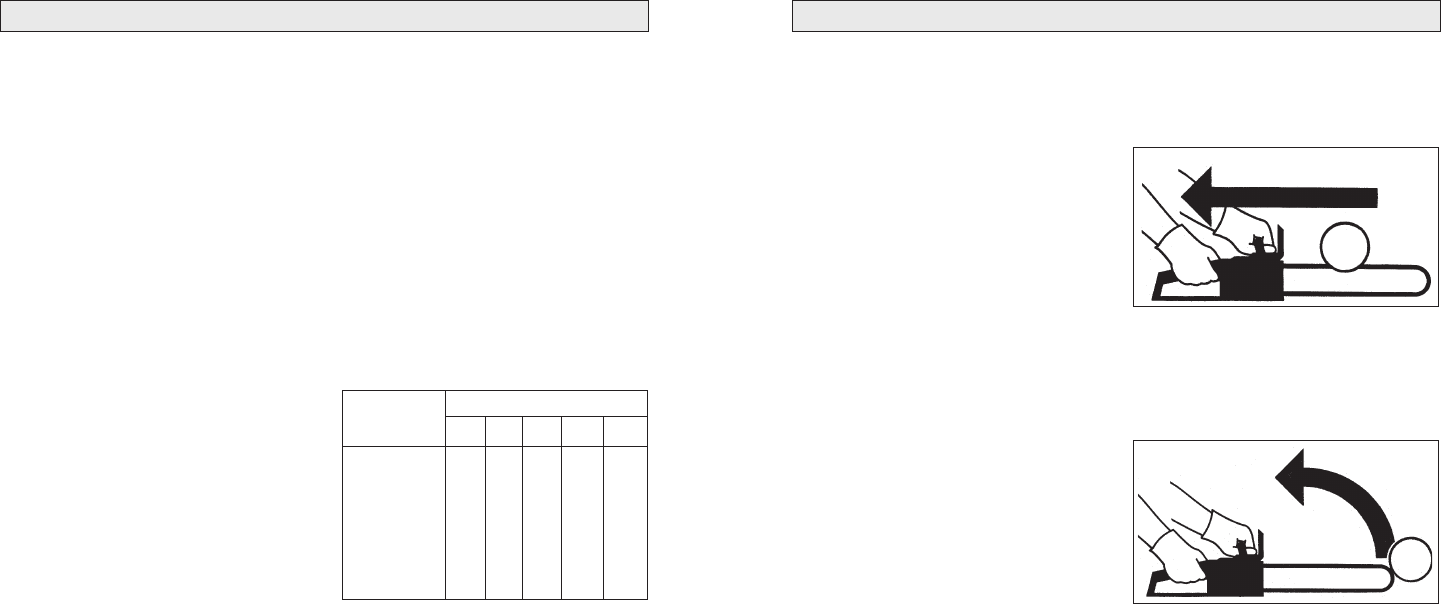

Kickback

The backward or upward motion, or both

of the guide bar occurring when the saw

chain near the nose of the top area of the

guide bar contacts any object such as a

log or branch, or when the wood closes in

and pinches the saw chain in the cut.

Kickback, Pinch (Fig. 4)

The rapid push back of the saw which can

occur when the wood closes in and

pinches the moving saw chain in the cut

along the top of the guide bar.

Low-Kickback Chain

A chain that complies with the kickback

performance requirements of ANSI B175.1-

2000 when tested on a representative

sample of chain saws.

Normal Cutting Position

Those positions assumed in performing the

bucking and felling cuts.

Notching Undercut

A notch cut in a tree that directs the trees

fall.

Oiler Control

A system for oiling the guide bar and saw

chain.

Rear Handle

The support handle located at or toward

the rear of the saw.

Fig. 4

Kickback, Rotational (Fig. 5)

The rapid upward and backward motion of

the saw which can occur when the mov-

ing saw chain near the upper portion of

the tip of the guide bar contacts an object,

such as a log or branch.

Fig. 5