10 11

4 - FUEL AND LUBRICATION

4-1. FUEL

Use regular g

rade unleaded gasoline mixed with Genuine

Factory Parts 40:1 custom 2-cycle engine oil for best

results. Use mixing ratios in Section 4-3.

Never use straight gasoline in your unit.This will cause

permanent engine damage and void the manufactur-

er’s warranty for that product. Never use a fuel mixture that

has been stored for over 90 days.

If 2-cycle lubricant other than Genuine Factory Parts

Custom Lubricant is to be used, it must be a premium

grade oil for 2-cycle air cooled engines mixed at a 40:1

ratio. Do not use any 2-cycle oil product with a recommend-

ed mixing ratio of 100:1. If insufficient lubrication is the

cause of engine damage, it voids the manufacturer’s

engine warranty for that occurrence.

4-2. MIXING FUEL

Mix fuel with Genuine Factory Parts brand 2 cycle oil in an

approved container. Use mixing table for correct ratio of fuel

to oil. Shake container to ensure thorough mix.

Lack of lubrication voids engine warranty.

4-3.FUEL AND LUBRICATION SYMBOLS

FUEL MIXING TABLE

4-4.RECOMMENDED FUELS

Some conventional gasolines are being blended with oxy-

genates such as alcohol or an ether compound to meet

clean air standards. Your McCulloch engine is designed to

operate satisfactorily on any gasoline intended for automo-

tive use including oxygenated gasolines.

4-5.CHAIN AND BAR LUBRICATION

Always refill the chain oil tank each time the fuel tank is

refilled. We recommend using Genuine Factory Parts

Chain, Bar and Sprocket Oil, which contains additives to

reduce friction and wear and to assist in the prevention of

pitch formation on the bar and chain.

Gasoline and Oil

Mix 40:1

Oil Only

5 - OPERATING INSTRUCTIONS

5-1. ENGINE PRE-START CHECKS

WARNING

Never start or operate the saw unless the bar and chain are

proper

ly installed.

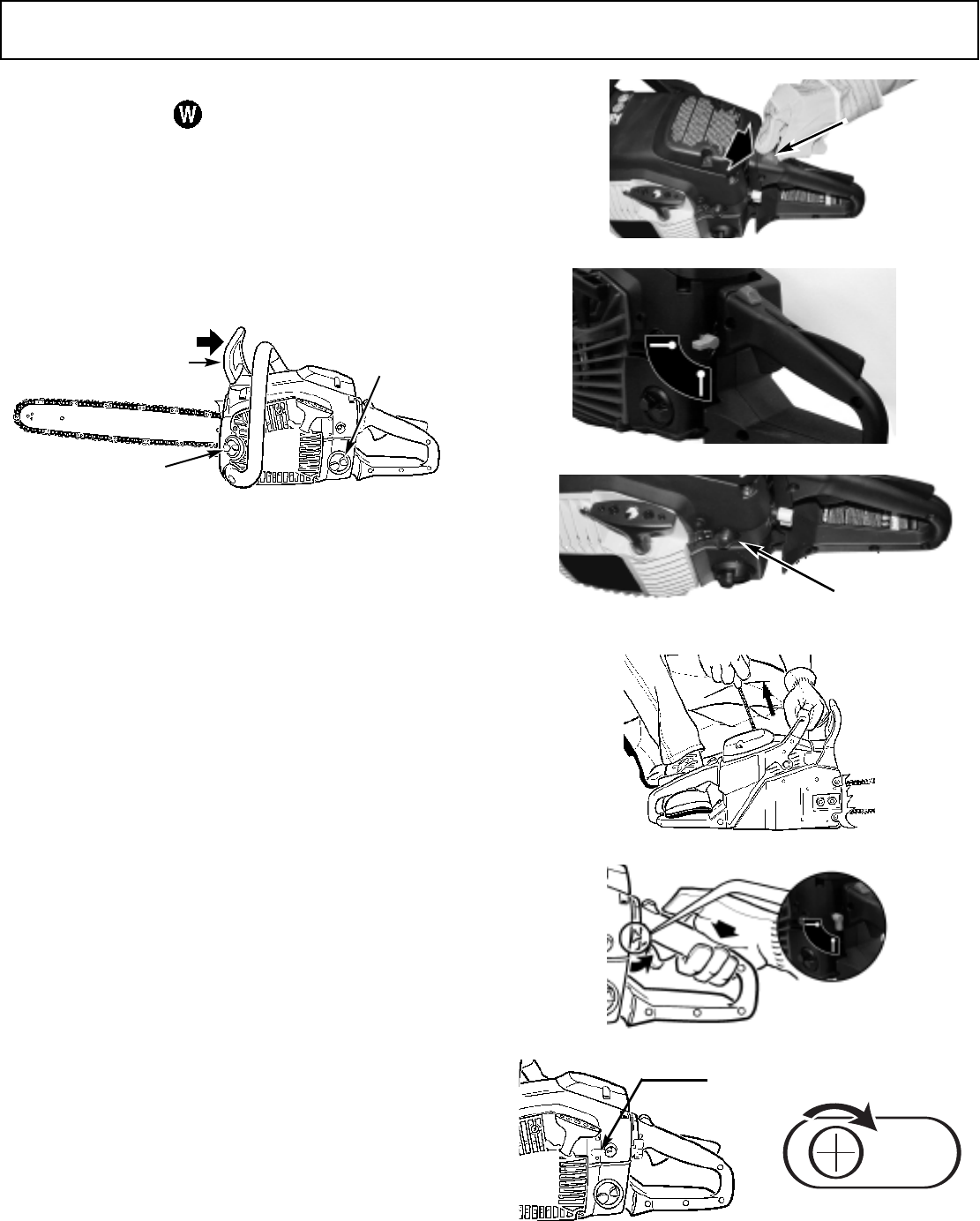

1. Fill the fuel tank (A) with correct fuel mixture (Figure 5-

1A).

2. Fill the oil tank (B) with correct chain and bar oil (Figure

5-1A).

3. Be certain the CHAIN BRAKE

®

is disengaged (C)

before starting unit (Figure 5-1A).

5-2.TO START ENGINE

1. Slide the STOP switch down (Figure 5-2A).

2. Rotate the choke lever up to the horizontal position

(Figure 5-2B).

3. Pump primer bulb 10 times (Figure 5-2C).

4. Pull starter rope 4-6 times, engine should start (Figure

5-2D).

5. If engine failed to start, rotate choke lever down to ver-

tical position then repeat step 4 (Figure 5-2D).

6. When engine starts, warm up 10 sec. Then depress

safety/throttle trigger.The automatic choke will disen-

gage

when tr

igger is pulled (Figure 5-2E).

7. Release throttle trigger for idle.

TO STOP: Slide stop switch up.

IMPOR

T

ANT IDLING INFORMA

TION

In some cases due to operating conditions (altitude, tem-

per

ature etc.) y

our chain sa

w may need a slight adjustment

to the idle speed.

After warm up - See the section 5-2, step 8 - If unit does

not Idle after restarting 2 times, follow these steps to adjust

idle.

1. Idle adjustment access (A) - the symbol "T" (for throttle)

is belo

w the adjustment hole (Figure 5-2F).

2. Using a Phillips or slotted screwdriver - turn screw 1/4

to 1/2 tur

n clockwise (to the right). Unit should then idle

properly (Figure 5-2G).

NOTE: If chain turns while idling - turn screw back to the

left until chain stops and unit continues to idle.

5-1A

C

A

B

5-2A

D

5-2B

5-2C

D

Horizontal position

Vertical position

5-2D

5-2E

A

utomatic

A

B

5-2F

5-2G

A