20

RC5010 & RC6010 (540 RPM) and RCM5010 & RCM6010 (1000 RPM) Rotary Cutters 318-128M 8/28/08

Land Pride

Section 2: Operating Instructions

Table of Contents

Transporting The Cutter

!

CAUTION!

When traveling on public roads at night or during the day, use

accessory lights and devices for adequate warning to operators

of other vehicles. Comply with all federal, state and local laws.

1. Be sure to reduce tractor ground speed when turning

and leave enough clearance so the cutter does not

contact obstacles such as buildings, trees or fences.

2. Select a safe ground speed when transporting from

one area to another. When traveling on roadways,

transport in such a way that faster moving vehicles

may pass you safely.

3. When traveling over rough or hilly terrain, shift tractor

to a lower gear.

Cutter Set-up For Field Operation

!

WARNING!

The following operational procedures should be carried out by

the tractor operator. Other persons should be cleared of the

area even during cutter set-up. Cutter operation should be

stopped when in the vicinity of other persons.

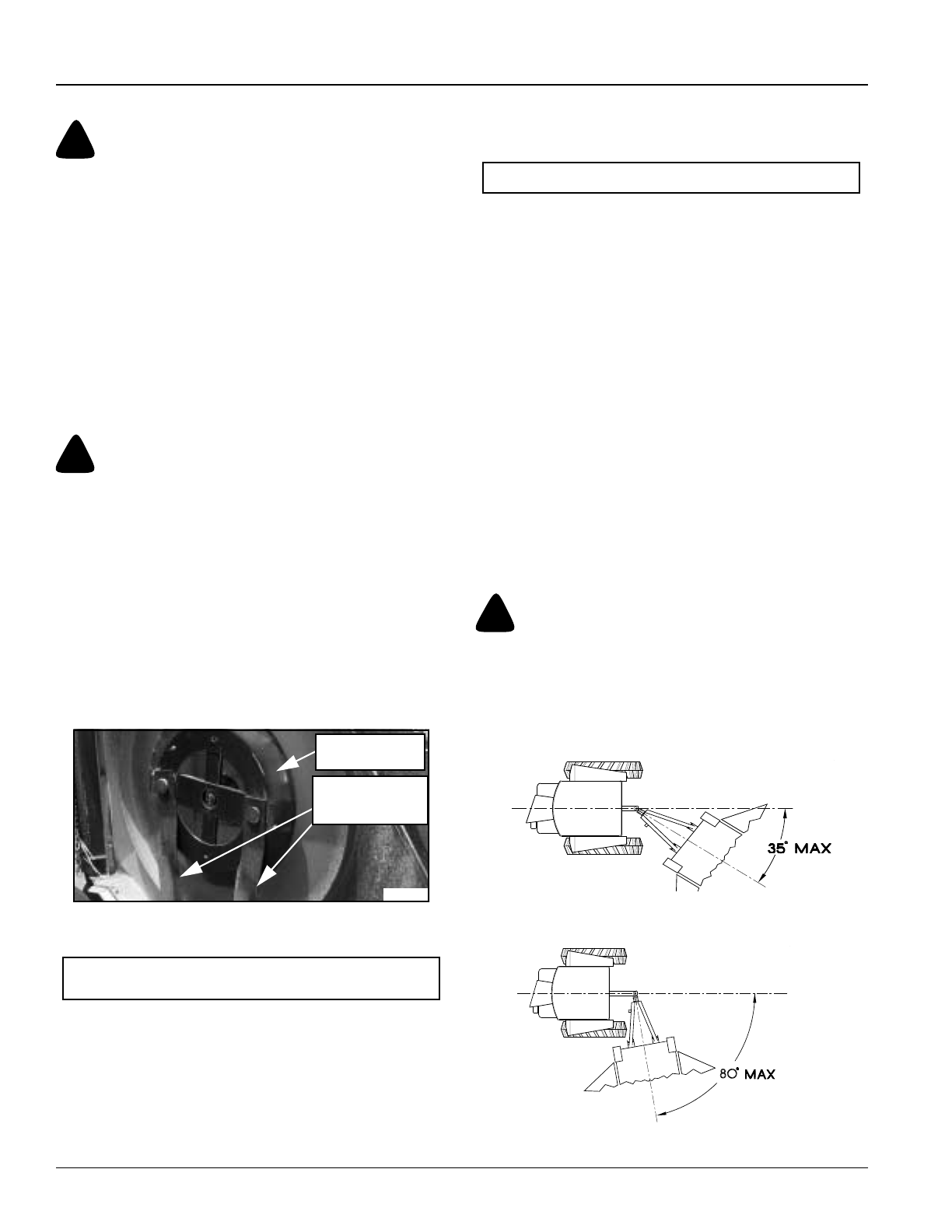

Refer to Figure 2-3:

1. Inspect the wing blade carrier and cutting blades

prior to lowering the wing. The cutting blades may

become locked together (overlapped) when the wing

is raised to transport position. Operating the cutter

under such circumstances will result in severe deck

vibration. Inspect the wing deck for a locked blade

condition prior to power-on operation. Use a pry bar

or other tool to separate the blades when necessary.

Wing Deck Blade Positioning

Figure 2-3

Refer to Figure 2-1 & Figure 2-2 on page 19:

2. Fully raise the wings to release any tension on the

transport lock bar as shown in Figure 2-1. Remove

hairpin clip (#1) from both the left and right cylinder

pins (#4).

3. Rotate end of transport lock bar (#3) to the storage

pin (#2) as shown in Figure 2-2. Secure with hairpin

clips (#1).

22169

Wing Deck

Cutting Blades

Blade Carrier

NOTE: The cutter height is controlled with a

hydraulic lift cylinder.

4. Lower the wing section to the down position.

5. Increase throttle to approximately 1/4 engine speed

and slowly engage driveline. Also see note below.

6. Ensure that all power shafts are rotating and that the

cutter has no vibration.

7. Continue to increase throttle to full 540 or 1000 PTO

speed before commencing forward operation.

Operating Speed & Turning Angle

Refer to Figure 2-4 & Figure 2-5:

Optimum ground speed depends on the density of the

material being cut, the horsepower rating of the tractor,

and terrain. Always operate the tractor at the cutter’s full

rated PTO speed in a gear range that allows the cutter to

make a smooth cut without lugging the tractor down,

usually between 2 to 5 mph.

Avoid tractor-to-cutter turning angles exceeding 35

degrees (Figure 2-4) if the main driveline is a standard

conventional shaft. Turning angle may be increased to

80 degrees (Figure 2-5) if the cutter is equipped with a

constant velocity driveline shaft. These extreme angles

are intended for intermittent usage only and not

prolonged usage. Plan your field cutting to minimize the

number of turns as well as extreme turning angles.

!

WARNING!

Do not operate this cutter under any terrain conditions where,

on a continuous cut, the wing angle exceeds 45 degrees up.

Ensure that the wing wheels are in continuous ground contact

at all times. Use the float position of your tractor’s hydraulic

system to provide automatic wing float position for varying

terrain conditions.

Conventional U-Joint Driveline

Figure 2-4

Constant Velocity (CV) Driveline

Figure 2-5

NOTE: Use tractor’s PTO soft start option if available.

11934

20795