12

RC5010 & RC6010 (540 RPM) and RCM5010 & RCM6010 (1000 RPM) Rotary Cutters 318-128M 8/28/08

Land Pride

Section 1: Assembly and Set-up

Table of Contents

Section 1: Assembly and Set-up

Tractor Requirements

Horsepower

The cutter is designed to be used on tractors with 50 to

250 hp.

Hitch

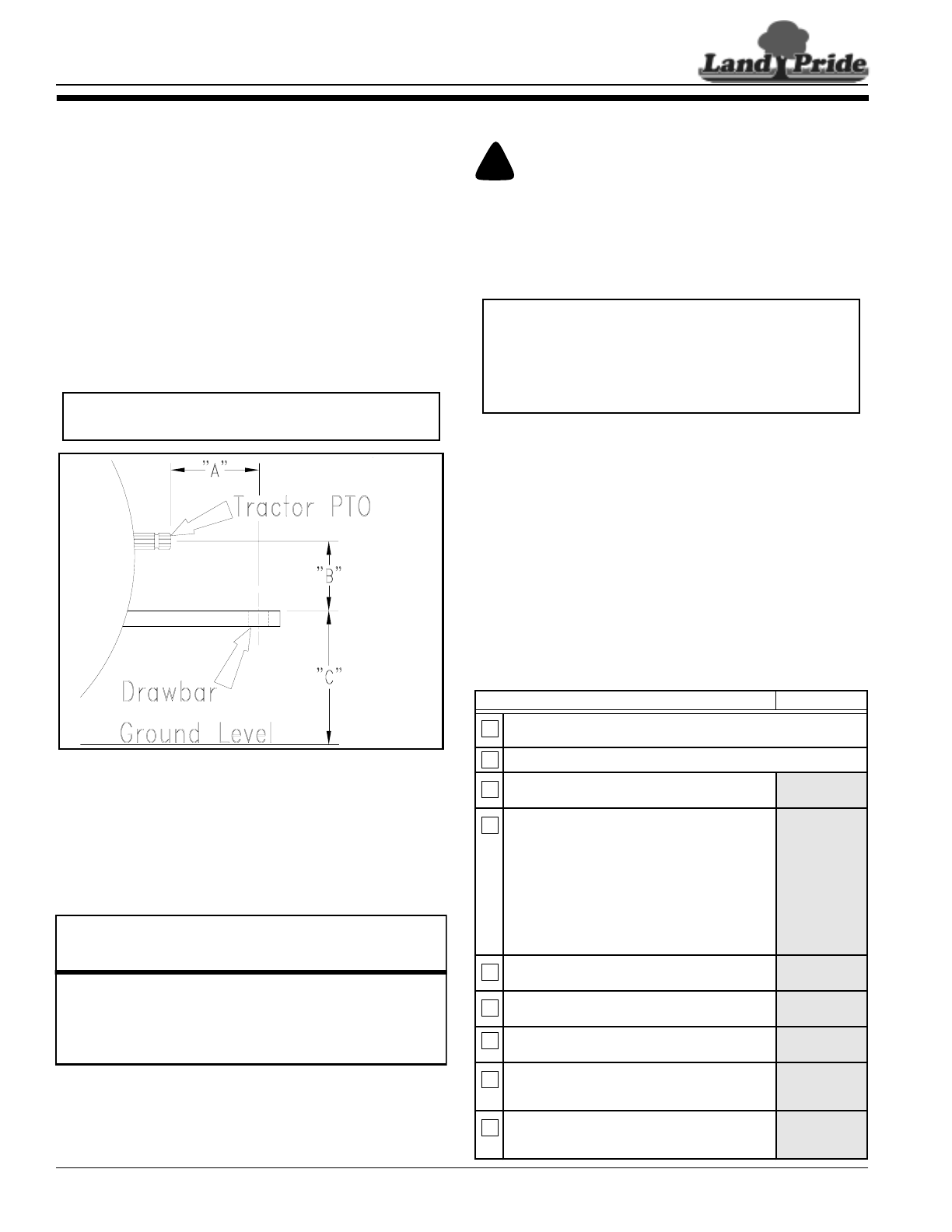

Refer to Figure 1-1:

The cutter uses a drawbar type hitch hook-up. Maintain

proper distance, dimension “A”, between center of

drawbar hitch pin hole and end of tractor PTO shaft.

• “A” = 14" for 540 rpm

• “A” = 16" for 1000 rpm

• “C” = 18” to 21” for 540 rpm and 1000 rpm

PTO to Drawbar Distance

Figure 1-1

Hydraulic Outlets

Two duplex outlets are required. One to raise and lower

the cutter and one to raise and lower the wing.

Optional control valve kits are available from your local

Land Pride dealer if the tractor is not properly equipped.

IMPORTANT: PTO damage may occur if distance

“A” is not properly maintained.

22273

Land Pride Control Valve Kits

Part No. Part Description

312-315A 3 SPOOL CONTROL VALVE KIT

For use with single duplex outlet.

312-316A SELECTOR CONTROL VALVE KIT

For use with single duplex outlet.

PTO Speed

!

CAUTION!

Do not over speed the PTO. The cutter can be damaged when

operated above its rated PTO RPM.

Rear PTO Speed:

Model RC5010 & RC6010 . . . . . . . . . . . . 540 RPM

Model RCM5010 & RCM6010 . . . . . . . . 1000 RPM

Before You Start

Read and understand the operator’s manual for your

cutter. An understanding of how it works will aid in the

assembly and set-up of your cutter.

It is best to go through the Pre-Assembly Checklist

before assembling the cutter. Speed up your assembly

task and make the job safer by having all the needed

parts and equipment readily at hand.

Torque Requirements

Refer to “Torque Values Chart” on page 42 to determine

correct torque values when tightening hardware.

Pre-Assembly Checklist

Check Reference

Have a fork lift or loader with properly sized chains and safety

stands capable of lifting and supporting the equipment on hand.

Have a minimum of two people available during assembly.

Make sure all major components and loose

parts are shipped with the machine.

Operator’s

Manual

Double check to make sure all parts, fasteners

and pins are installed in the correct location.

Refer to the Parts Manual if unsure. By double

checking, you will lessen the chance of using a

bolt incorrectly that may be needed later.

NOTE: All assembled hardware from the factory

has been installed in the correct location.

Remember location of a part or fastener if

removed during assembly. Keep parts

separated.

Operator’s

Manual

330-323M

Parts Manual

330-323P

Make sure working parts move freely, bolts are

tight & cotter pins are spread.

Operator’s

Manual

Make sure all grease fittings are in place and

lubricated.

Page 32

Make sure all safety labels are correctly located

and legible. Replace if damaged.

Page 4

Make sure all red and amber reflectors are

correctly located and visible when machine is in

transport position.

Page 9

Make sure all tires are inflated to the specified

psi air pressure and all wheel bolts and axle

nuts are tightened to the specified torque.

Page 42

IMPORTANT: Do not attempt to operate a 540 RPM

driveline with a 1,000 RPM PTO tractor or a 1,000

RPM driveline with a 540 RPM PTO tractor. Many

tractors provide both 540 and 1,000 RPM PTO

modes. Check your tractor’s manual to determine its

capabilities.