16

RC5010 & RC6010 (540 RPM) and RCM5010 & RCM6010 (1000 RPM) Rotary Cutters 318-128M 8/28/08

Land Pride

Section 1: Assembly and Set-up

Table of Contents

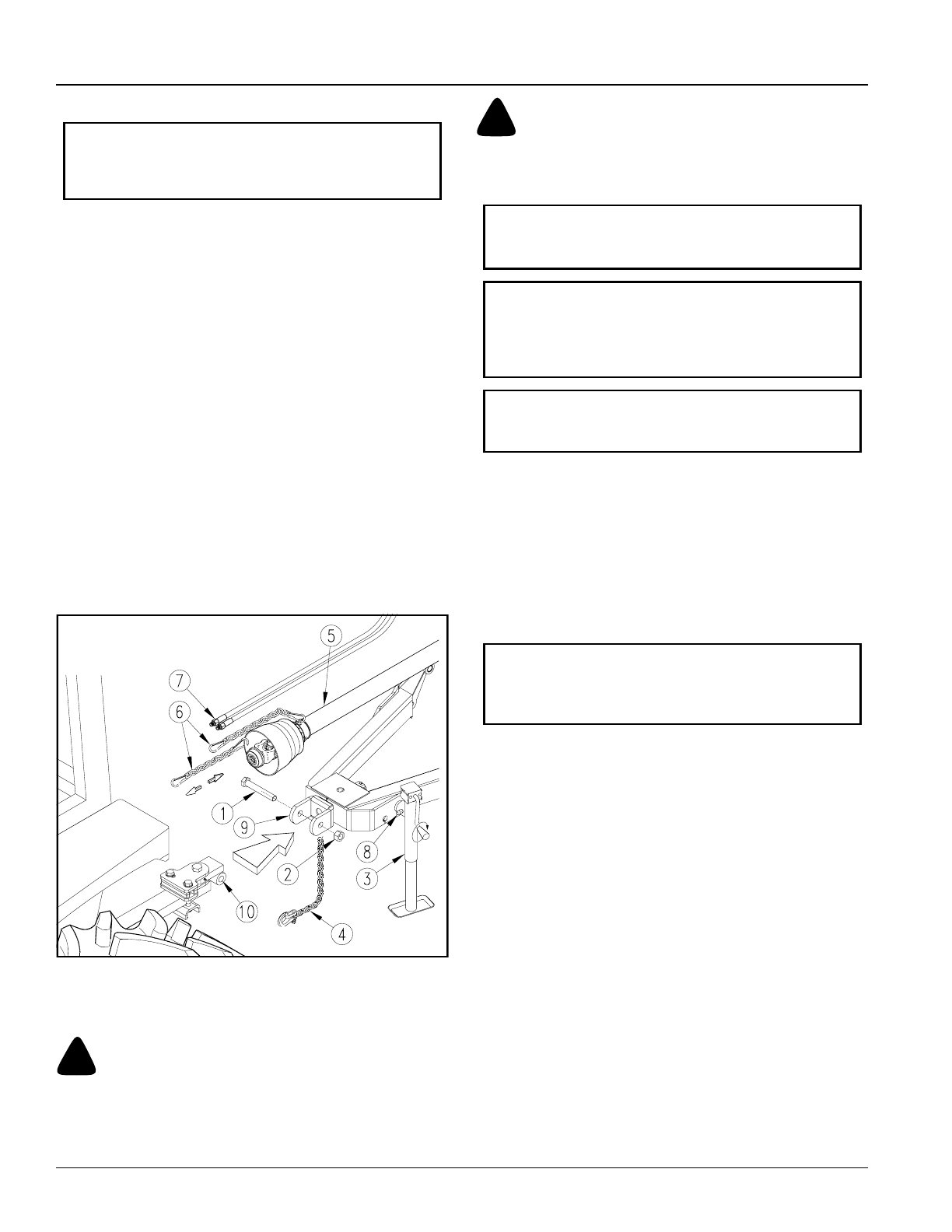

Refer to Figure 1-10:

2. Make certain the parking jack (#3) is properly

attached to the cutter and secured with attachment

pin (#8).

3. Back tractor within close proximity of cutter hitch.

4. Raise or lower parking jack (#3) to align hitch (#10)

with bolt hole in swivel clevis (#9).

5. Back tractor up to cutter swivel hitch (#9) until hole in

hitch weldment with bushing (#10) aligns with holes

in swivel clevis (#9).

6. Insert 1" x 6 1/2" gr5 hex bolt (#1) through the cutter

swivel hitch (#9) and hitch weldment (#10). Secure

hex bolt with lock nut (#2). Tighten lock nut snugly to

remove all play. Do Not torque 1" lock nut.

7. Lower parking jack (#3) until cutter weight is

removed from the jack. Remove parking jack from

the hitch and store it on the storage base located on

top of the weight box.

8. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

Tractor Hookup to Bar-Tite Hitch

Figure 1-10

Driveline Installation

!

DANGER!

Do not engage tractor PTO while hooking-up and unhooking

the driveline or stand near a rotating driveline. A person’s body

and/or clothing can become entangled in the driveline resulting

in serious injury or death.

IMPORTANT: Parking jack attachment pin (#8)

must be fully inserted and secured before working

on or around a cutter that is not hooked to the tractor

drawbar.

22262

!

CAUTION!

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key and wait for blades to come a

complete stop before dismounting from tractor.

The main driveline may be either constant velocity type

or conventional type. Pull-collar couplers and retaining

bolts are used to connect the driveline to the tractor and

implement gearbox.

A driveline that is too long can damage the tractor,

gearbox and/or driveline. Always check driveline length

with cutter hitched to the tractor before engaging the

PTO.

Check Driveline Length

1. Park tractor and cutter in a straight line on a level

surface. Place gear selector in park, shut tractor

engine off, set park brake and remove switch key.

2. Attach pull-collar coupler to tractor PTO shaft and

bolted coupler to divider gearbox shaft. Skip to step 5

if driveline fits between tractor and implement.

Refer to Figure 1-11:

3. The PTO driveline will require shortening if it does

not fit between tractor and cutter gearbox. Shorten

driveline as follows:

a. Pull driveline apart as shown in Figure 1-11.

b. Attach pull-collar coupler to the tractor PTO shaft

and bolted coupler to the divider gearbox shaft.

Pull on each driveline section to be sure the

universal joints are secured to the shafts.

c. Hold driveline sections parallel to each other to

determine if they are too long. The inner and outer

shields on each section should endapproximately

1" short of reaching the universal joint shield on

the adjacent section (see “B” dimension). If they

are too long, measure 1" (“B” dimension) back

from universal joint shield and make a mark at this

location on the inner and outer driveline shields.

IMPORTANT: The driveline must be lubricated

before putting it into service. Refer to “Lubrication

Points” on page 32.

IMPORTANT: Do not attempt to operate a 540 RPM

driveline at 1,000 RPM or a 1,000 RPM driveline at

540 RPM. Many tractors provide both 540 and 1,000

RPM PTO speeds. Check your tractor’s manual to

determine its capabilities.

IMPORTANT: Read and understand “Section 2:

Operating Instructions” beginning on page 19 before

operating the Rotary Cutter.

IMPORTANT: The Rotary Cutter must be hitched

with tractor and cutter aligned in a straight line on a

level surface. This arrangement provides correct

alignment between tractor and gearbox PTO shafts.