English – 31

MAINTENANCE

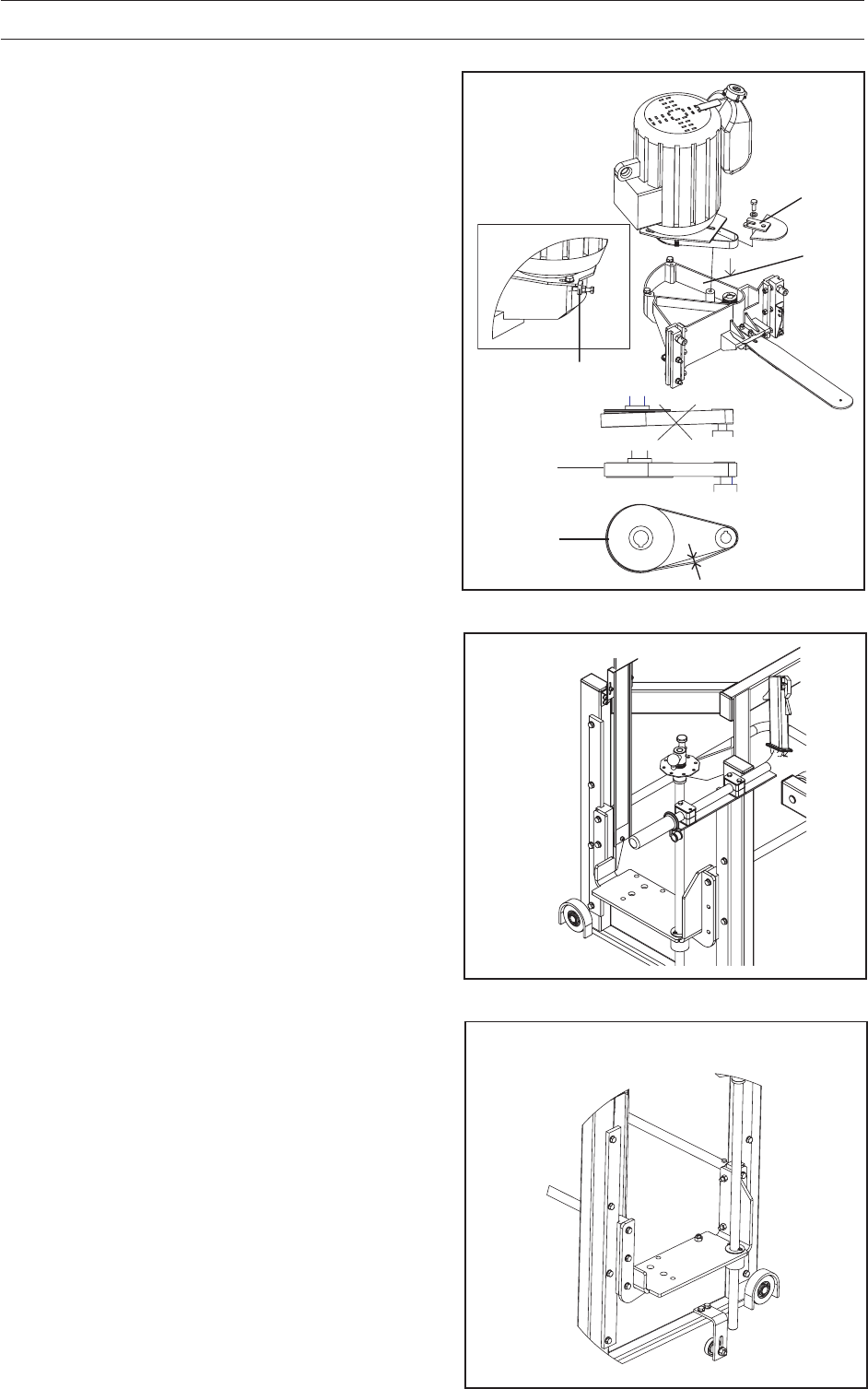

FIG. 56

FIG. 54

FIG. 55

Drive belt

Chain sawmill with electric motor

(FIG. 54)

The drive belt becomes worn as the sawmill is used.

The belt should be replaced after 200 hours of

operation to avoid a belt failure during operations. If

the drive slips or the belt needs to be adjusted

frequently, this is a sign that the belt needs to be

replaced. Replace the belt as follows:

1. Disconnect the connector from the distribution

box.

2. Disconnect the belt guard (A).

3. Completely remove the belt adjuster (B).

4. Disconnect the electric motor by loosening the

screws.

5. Carefully lift up the motor and replace the belt.

6. Ensure that the belt is correctly positioned in the

tracks (C) on both pulleys.

7. Screw the motor into position and tension the belt

with the tension screw (B). Check the belt tension

with your thumb (D) and install the belt guard (A).

B

C

D

A

E

10 mm

Adjusting the saw saddle

The saw saddle’s plastic guides may need to be

adjusted after a few hours of use. This is done as

follows:

1. Slacken off the three mounting nuts.

2. Screw in the two adjustment screws until there is

no play, then tighten the nuts.

3. Check the position of the bar in relation to the log

bolsters and adjust if required, see page 20.

The saw unit’s height

adjustment

Maintenance procedures on the components listed

below are necessary in order to assure the saw

chain’s vertical adjustment.

Runners

The guides that locate the saw saddle should be

wiped clean and moistened with oil as required.

Height adjustment screw

The screw must be wiped clean and lubricated if

necessary.