PR-Series Operator’s Manual-E/F 31

Service

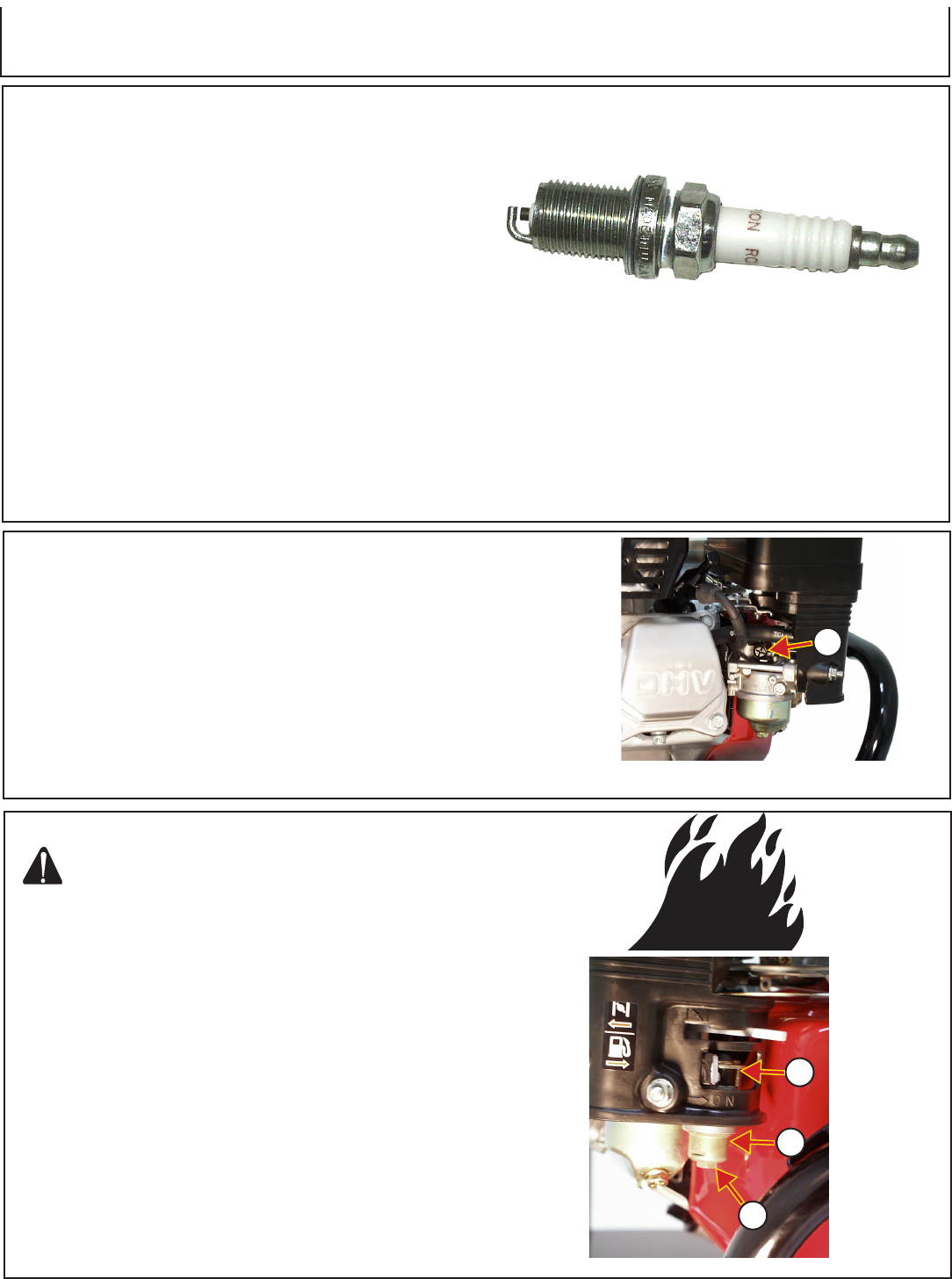

ADJUSTING RPM

1. Start engine. Allow it to warm to normal operating

temperature.

2. Move throttle lever to its minimum position.

3. With engine idling, turn throttle stop screw (A) to obtain

standard idle speed.

NOTE: Standard idle speed is 1250 - 1550 RPM.

NOTE: Idle should be serviced every 300 hours by an

authorized dealer. Operator should adjust only if

mechanically procient and using proper tools.

PIC98-102299R0

DWG15-102299R0

CLEANING SEDIMENT CUP

CAUTION: Clean sediment cup in a well ventilated

area, away from sparks or ame, including any

appliance with a pilot light. Do not use gasoline

or a low ash-point solvent to clean the fuel valve.

A re or explosion could result.

NOTE: AC-2400G illustrated, but procedure is the same for

other washers.

NOTE: Clean sediment cup after every 100 hours of use.

1. Turn fuel valve (A) to left as illustrated to shut off the

fuel ow.

2. Remove cap screw (B) with a 10mm wrench. Remove

sediment cup (C) and o-ring.

3. Remove any sediment or other foreign matter and

wash in nonammable or high ash point solvent. Dry

thoroughly.

4. Install o-ring and sediment cup with cap screw.

5. Turn fuel valve right to “ON” position and check for fuel

leaks.

PIC100-102299R0

A

A

B

C

CLEANING AND GAPPING SPARK PLUG

1. Remove and inspect spark plug. If porcelain is cracked

or electrodes are pitted, install a new spark plug. (See

step 5.)

IMPORTANT: Do not clean spark plug in a machine

using abrasives.

2. If spark plug is in good condition, clean plug by scraping

or using a wire brush. Wash with a commercial

solvent.

3. Use a round wire-type feeler gauge to check for a gap

of 0.70 to 0.80 mm (0.028 to 0.031 inches.)

4. Carefully bend outer electrode to adjust gap.

5. Install spark plug.

Reinstalling used plug: Tighten 1/8 - 1/4 turn after spark

plug seats to compress washer.

Installing new plug: Use NGK BPR6ES

PIC99-102299R0