10-17 109706 10/08

WARNING: Explosive separation of a tire and rim can cause serious injury or death.

Do not attempt to mount a tire without the proper equipment and experience to perform the task.

Always maintain the correct tire pressure and never over inflate.

Never weld or heat a wheel and tire assembly as an explosion may occur. Welding can weaken or

deform a wheel.

When inflating tires stand to one side and not in front of or over the tire assembly.

Check tires for low pressure, blemishes, damaged rims or missing lug bolts and nuts.

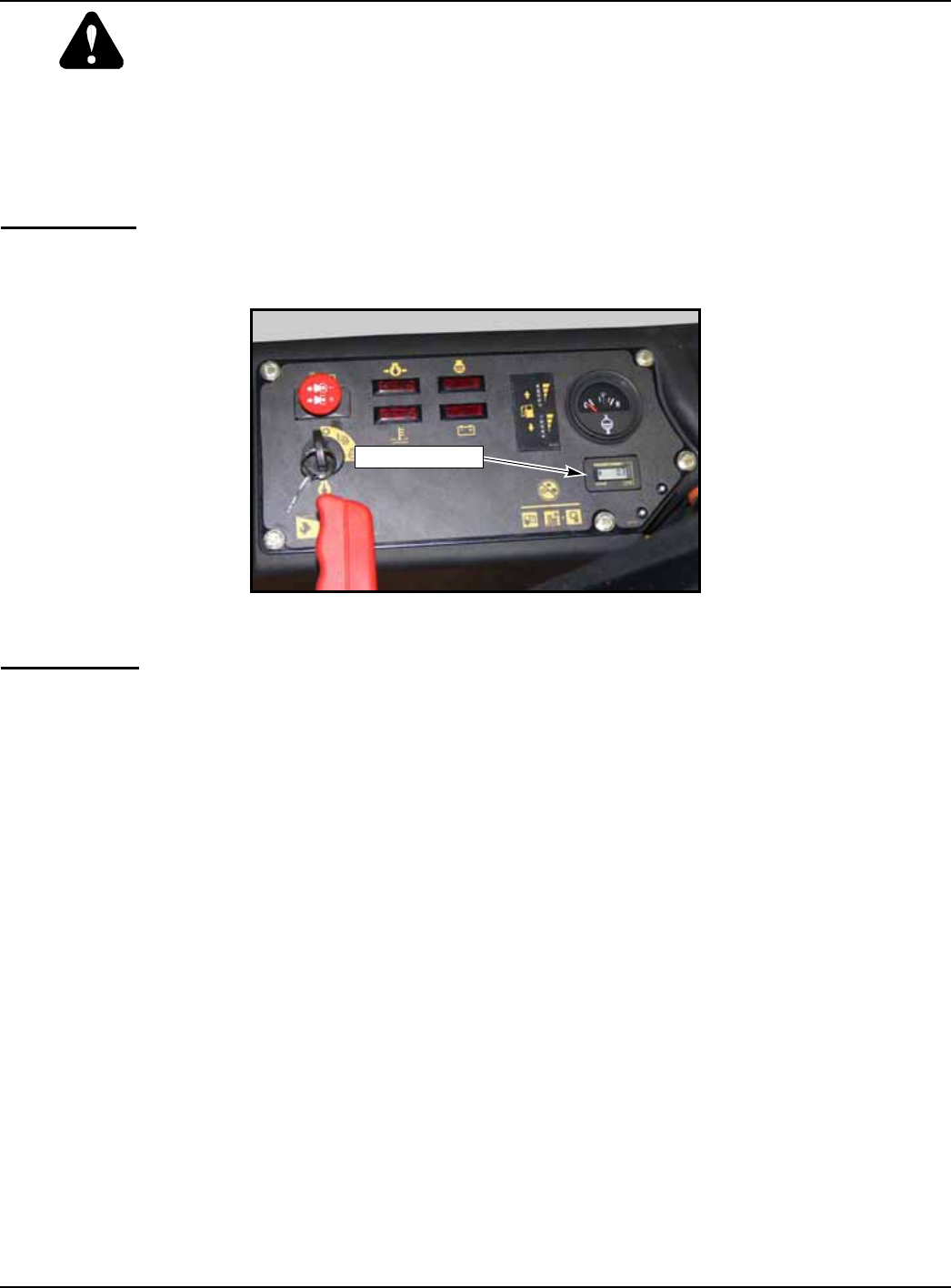

Hour meter

To recognize when your machine needs servicing, check the hour meter and the maintenance schedule. The hour

meter shows the number of hours the engine has run, and the maintenance schedule lists the service intervals

(FIG. 27).

Lubrication

1. Grease the front gauge wheel bearings per the Maintenance Schedule. Use SAE multi-purpose grease.

2. Grease the four deck lift pivots, located to the side of the operator’s footrest per the Maintenance Schedule. Use

SAE multi-purpose grease.

3. Grease the deck idler per the Maintenance Schedule. Use SAE multi-purpose grease.

4. Grease the pump idler per the Maintenance Schedule. Use SAE multi-purpose grease.

5. Grease the two deck pusher arm pivots per the Maintenance Schedule. Use SAE multi-purpose grease.

6. Grease the blade spindle assemblies per the Maintenance Schedule. The spindle assemblies require lubrication

annually. Each spindle shaft is equipped with a grease zerk located under the deck. Use no more than one or two

ounces of SAE multi-purpose grease, (1 to 2 pumps on an average grease gun). Do not force lubricant into grease

zerks. Bearings are sealed and do not require much lubricant.

FIG. 27

HOUR METER