44 – English

NOTE!

If a new piston or cylinder has been fitted

the saw must be run for the first 3–4

hours with carburettor adjusted to the

factory settings.

Piston and cylinder – refitting 340, 345

1-5

See Piston and cylinder 346XP, 350, 351, 353 –

Refitting points 1-5.

6

Apply silicone adhesive/sealing compound (03-

7062) to the crankcase’s contact surfaces with the

cylinder.

Carefully slide the cylinder down over the piston

towards the big end bearing.

Note!

Work is facilitated if the crankshaft complete with

bearing and piston is released from the crankcase

and the piston is pushed into the cylinder. The unit

is then refitted in the crankcase.

7

Fit the cylinder bolts, tightening crosswise to a

torque of 13–15 Nm.

8

Pressure test the cylinder.

9

Refit:

• spark plug, tighten to a torque of 15 Nm

• carburettor, see “Carburettor – refitting”,

• silencer, tighten to a torque of 8–10 Nm

• cylinder cover

• Loosen the carburettor bolts so that the carbu-

rettor can be moved back about 4 mm. Insert

cover plate 502 54 11-02 between the carburet-

tor and the carburettor flange. Tighten the

carburettor bolts to a torque of 1–1.5 Nm.

• Loosen the silencer bolts so that the silencer

can be moved back about 4 mm. Insert cover

plate 502 54 11-02 between the silencer and the

exhaust flange on the cylinder flange. Tighten

the silencer bolts to a torque of 8–10 Nm.

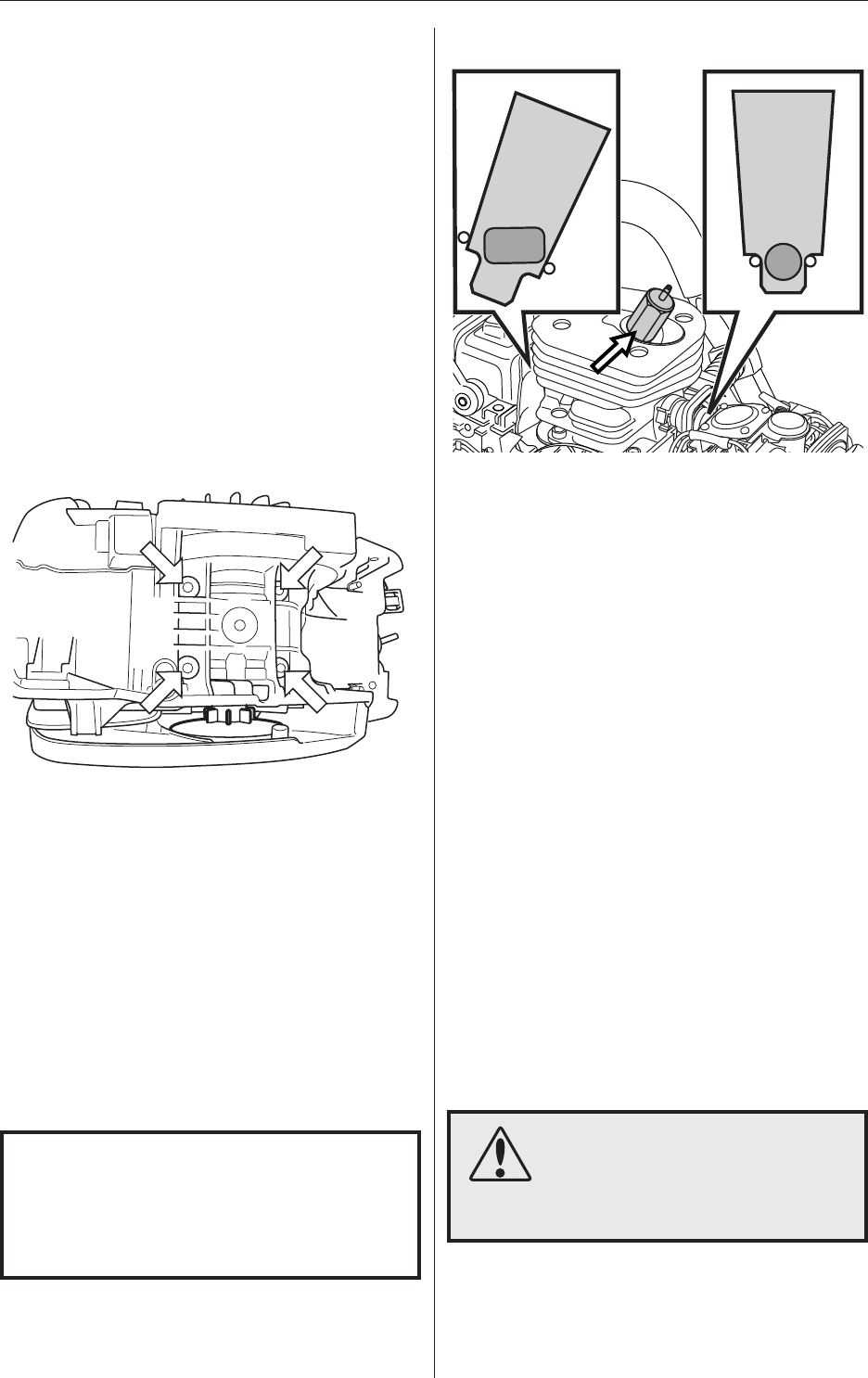

• Unscrew and remove the spark plug. Screw in

pressure test nipple 503 84 40-02. Connect tool

502 50 38-01 to the nipple. The decompression

valve must be closed. The decompression valve

must be closed. To check the decompression

valve itself, see “Decompression valve – pres-

sure testing”.

• Pump up the pressure to 80 kPa (0.8 bar).

• Wait 30 seconds.

• The pressure should not be less than 60 kPa

(0.6 bar).

• Remove the cover plates from the silencer and

carburettor, tighten the bolts to the specified

torque. Remove the pressure test nipple 503 84

40-02 and refit the spark plug.

WARNING!

After pressure testing the cylin-

der, check that the inlet manifold

is seated correctly, otherwise the

saw may be damaged.

Cylinder – pressure testing

Repair instructions