English – 33

Repair instructions

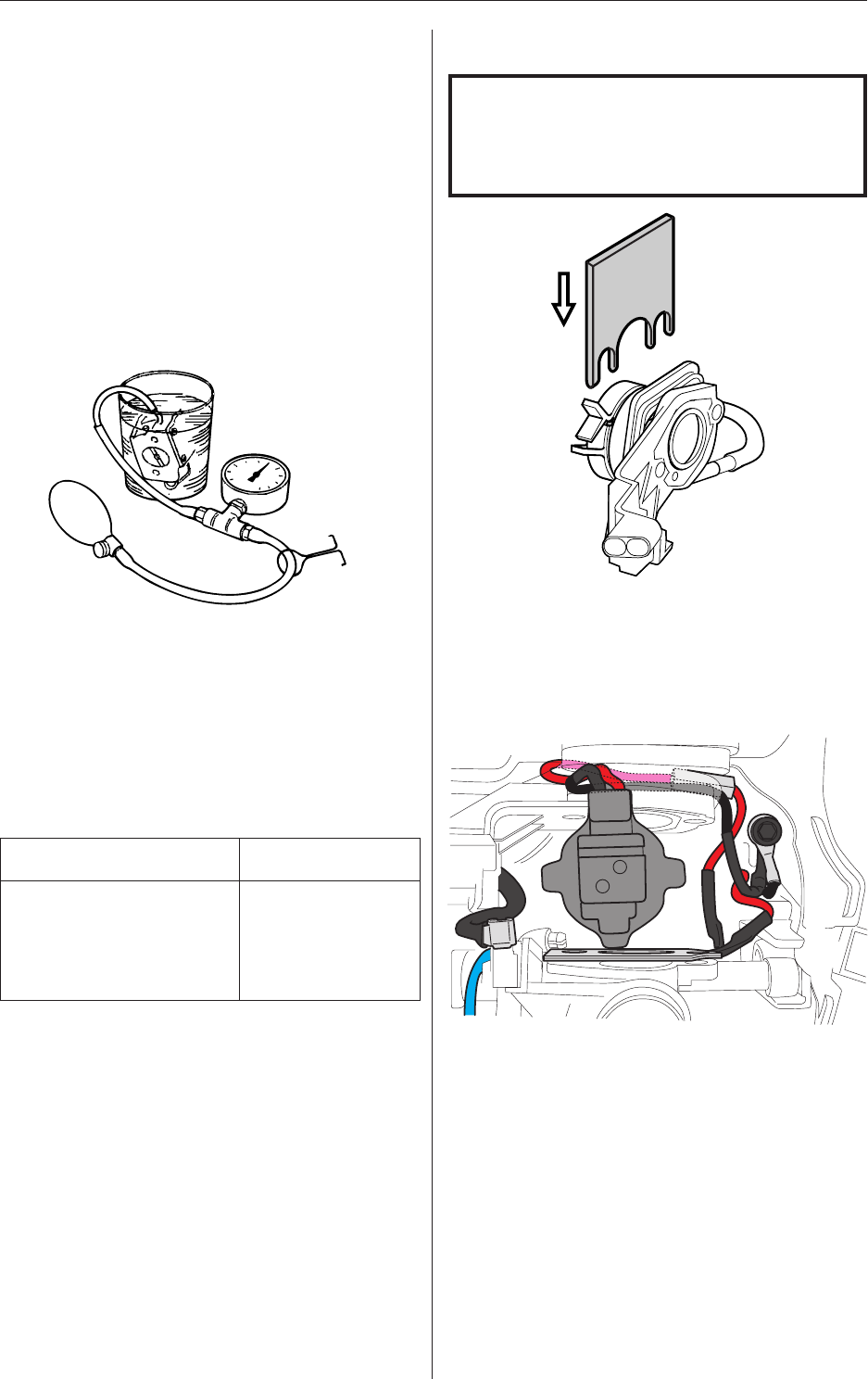

Carburettor – pressure testing

Pressure testing should be carried out with the

carburettor fully assembled. Testing should always

be carried out after the carburettor has been

repaired, but can also be performed for trouble-

shooting before dismantling.

Carry out the test as follows:

• Screw in the high and low speed jet screws and

back them off one turn.

• Connect pressure tester 502 50 38-01 to the

carburettor fuel inlet.

• Lower the carburettor into a beaker of water.

• Pump up the pressure to 50 kPa (0.5 bar) and

clamp the pump tube.

• There should be no leakage. If leakage occurs,

refer to the table below.

Leakage Fault lies in

Diffuser jets Needle valve

In impulse tube Pump diaphragm

Ventilation hole above

metering unit Control diaphragm

Fit stop plate 502 54 17-01 between the carburet-

tor flange and the insulating plate.

On saws with a carburettor heater

346XPG, 351G, 353G

Carburettor – refitting

NOTE!

Cleanliness is very important when reas-

sembling the carburettor. Tiny particles of

dirt can cause operating problems.

1

Insert the heating element between the air filter

connection and carburettor as well as above the

carburettor. Route the cable as illustrated above.

Tighten the bracket above the carburettor with the

two bolts.

Connect the cables to the carburettor heater.