SKU 93889 For technical questions, please call 1-800-444-3353 PAGE 11

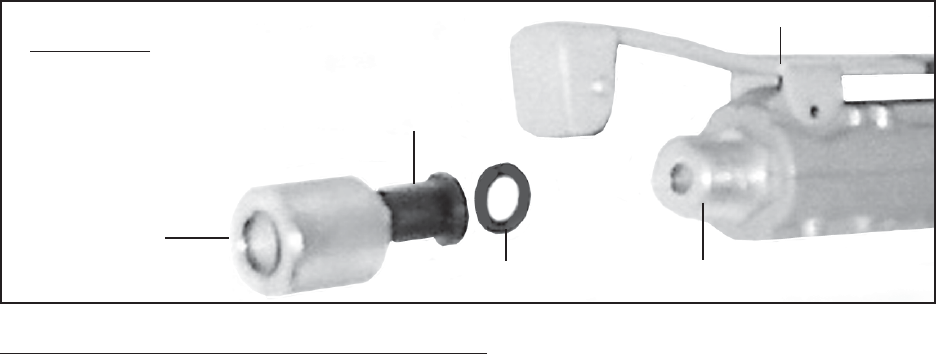

Cover (43). Position the Nozzle Gasket (41) against the Pipe Adapter (40).

Position the proper Nozzle against the Nozzle Gasket. Then screw the Nozzle

Cover back onto the Pipe Adapter to secure the Nozzle Gasket and Nozzle in

place. (See Figure H.)

FIGURE H

NOZZLE GASKET

(41)

PIPE ADAPTER

(40)

NOZZLE

(42, 42A)

NOZZLE COVER

(43)

SANDBLASTING GUN

4. Pull up and hold theT-Handle w/Seal (1) to seal the opening in the Tank

Assembly (3). (See Figure I.)

5. Turn the Media Metering Valve (18) and Air Input Valve (14) to the “ON” position.

At this point, the Tank Assembly (3) will begin to pressurize. (See Figure G.)

6. Once the Tank Assembly (3) is fully pressurized, release the T-Handle w/Seal (1).

The air pressure within the Tank should now hold the T-Handle w/Seal in place.

NOTE: Should an air leak develop around the T-Handle w/Seal, shut off the air

compressor. Turn the Media Metering Valve (18) and Air Input Valve (14) to the

“OFF” position. Use the Safety Valve (6) to release any remaining air pressure

within the Tank. Reposition the T-Handle w/Seal. Then, turn on the air

compressor and resume pressurizing the Tank. (See Figure G.)

7. Grip the Sandblasting Gun firmly with both hands.

To Operate The Pressure Blasting System:

1. If possible, place the workpiece inside a sandblast cabinet. Otherwise, isolate

the workpiece to make sure no damage can occur to nearby walls, tools, personal

property, etc.

2. Turn the Media Metering Valve (18) and Air Input Valve (14) to the “OFF” position.

(See Figure G.)

3. Connect the air compressor’s hose to the previously installed Quick Connector.

Then turn on the air compressor, and set its regulator between 65 to 125 PSI.

Do not exceed 125 PSI. (See Figure F.)