24 Generac

®

Power Systems, Inc.

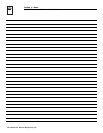

• If the compartment is lined with galvanized steel, it

may be constructed of any material. Generac rec-

ommends that the compartment be constructed of

1/2-inch thick plywood (not strandboard), with the

floor made of a double thickness of 1/2-inch ply-

wood with the grain of the wood at cross section

for added strength (Figure 6.5).

Figure 6.5 – Typical Compartment Construction

• If constructing a compartment, line the exterior

(underside) of the compartment floor with 26-

gauge galvanized steel.

• All seams, splices and joints of the compartment

walls (unless vapor tight by design) should be

caulked to prevent poisonous, flammable or explo-

sive vapors from entering the vehicle interior.

NOTE:

Caulking must be done so that the caulking mate-

rial will stay in place permanently. Pressing such

materials as putty tape onto joints and seams is

not acceptable. A high quality silicone rubber base

sealant is recommended.

• Holes and openings made in the compartment

walls to allow for the passage of electrical conduit,

conductors, hoses, cables, etc., into the vehicle liv-

ing area must be sealed vapor tight with silicone

rubber base sealant.

• If flexible metal conduit is used, it must be sealed

internally at the end where it terminates inside the

compartment’s electrical junction box.

NOTE:

Flexible metal conduit, due to its unique con-

struction, is NOT vapor tight along its entire

length.

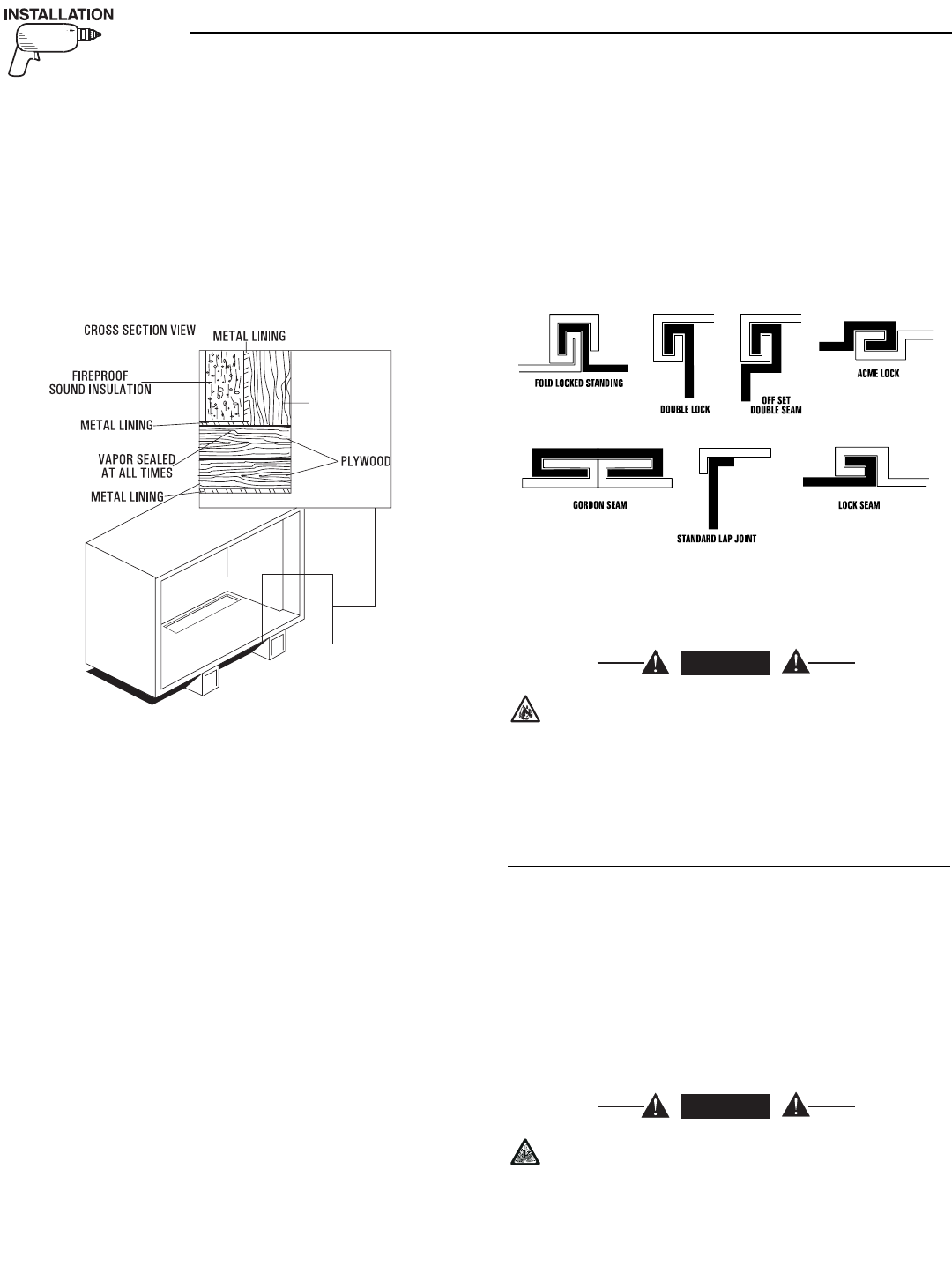

• Seams and joints of the galvanized steel (whether

used as a liner or for the compartment itself) must

be lapped and mechanically secured. Such seams

may be manufactured, welded, bolted, riveted or

screwed. Manufactured lock seams are shown in

Figure 6.6. Installer constructed compartments

typically utilize a standard lap joint.

Figure 6.6 – Types of Lock Seams

• After the compartment has been metal lined and

vapor sealed, line the compartment interior walls

and ceiling with an approved, nonflammable

sound insulating material. See Section 6.2.3.

Do not install any flammable material directly

above or around the compartment. Heat,

transferred through the compartment structure,

may be sufficient to ignite, char or discolor

seat cushions, fiberboard and other flammable

materials. Use approved nonflammable insulat-

ing materials in high temperature areas.

6.2.3 SOUND INSULATING MATERIALS

Once installers have determined that a compartment

is properly constructed and metal lined, they can add

acoustical material. This may include additional

sealant or insulating material, to reflect noise away

from the vehicle interior.

Sound insulating materials should be of a nonflam-

mable type. One excellent insulating material is a 1-

inch (25 mm) thick fiberglass having a 2-pound den-

sity. When fiberglass is used, its coated side should

face toward the compartment interior.

Do not install sound insulation or any

absorbent material on the compartment floor

interior. Such materials will become soaked

with combustible or explosive vapors and liq-

uids and will become a fire hazard.

DANGER

◆

DANGER

Section 6 – Installation

QUIETPACT 55, 65, and 75 Recreational Vehicle Generators