24

Figure 2.8 – Airflow Through Engine/Generator

2.3.2 TESTING THE INSTALLATION

The manufacturer recommends testing the installa-

tion to be sure adequate cooling airflow is available to

the unit before placing the unit into service. If the unit

shows signs of overheating, enlarge the air openings.

Never place a unit into service until absolutely certain

that cooling and ventilation is adequate.

NOTE:

Test the installation, especially if bringing in air

from below the generator set.

2.4 LP GAS FUEL SYSTEM

DANGER

LP gas is highly EXPLOSIVE. The gas is heavier

than air and tends to settle in low areas. Even

the slightest spark can ignite it and cause and

explosion. Only competent, qualified people

should be allowed to install, test, adjust or ser-

vice an LP gas fuel system. Install the optional

fuel system in compliance with applicable codes,

standards and regulations. After the installa-

tion, do not do anything that might render the

system in noncompliance with applicable codes

and standards.

The LP powered range of generators are fitted with a

nonadjustable, factory set system. These systems are

tamper-proof to meet 1997 California Air Resources

Board requirements for engine emission.

2.4.1 PARTS NOT INCLUDED IN FUEL

SYSTEM

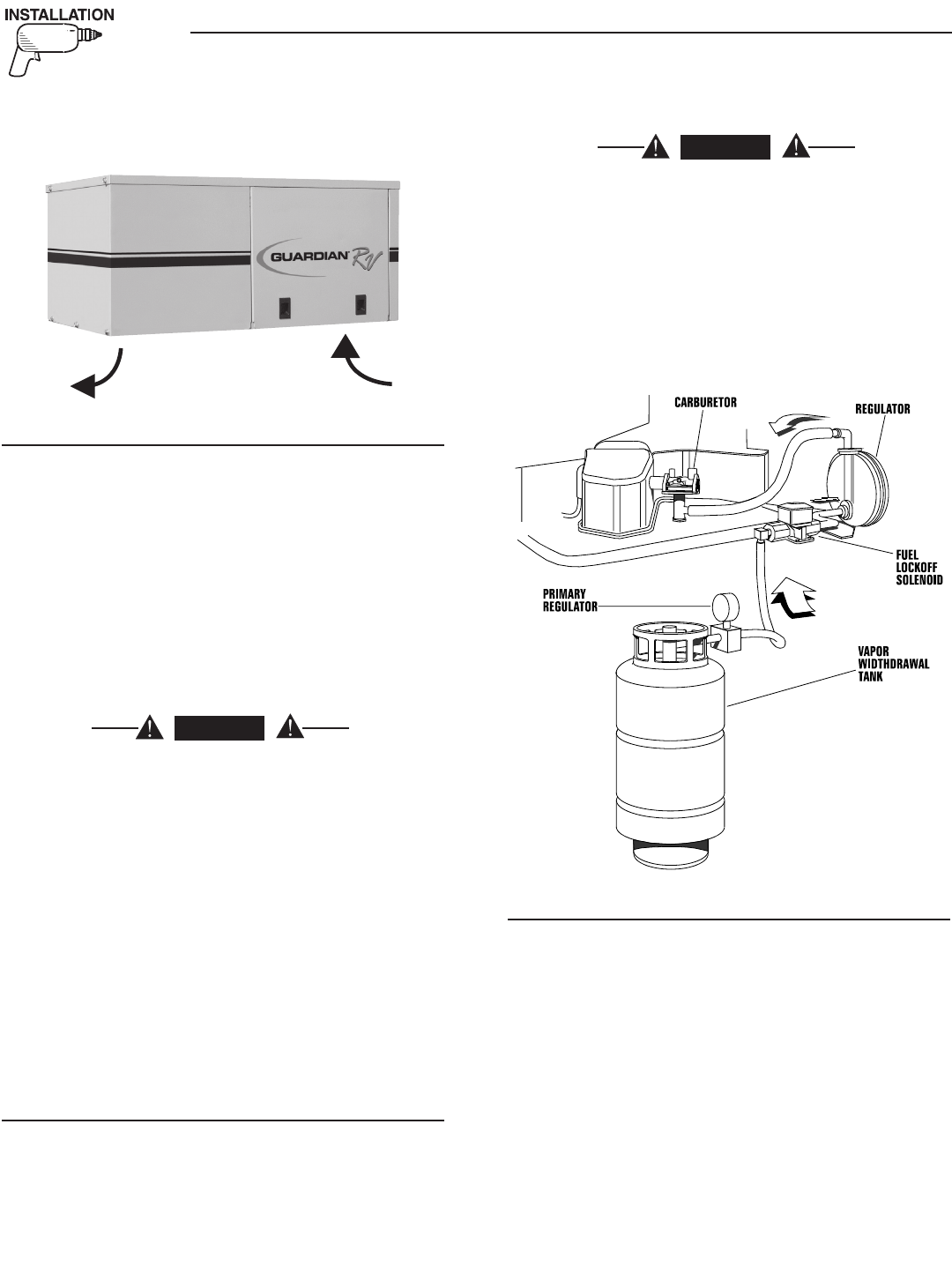

The propane fuel system does NOT include such

items as (a) gas tank, (b) gas piping, (c) fittings, (d)

valves, and (e) primary regulator, used to store the

gaseous fuel and deliver it to the gaseous fuel sole-

noid (Figure 2.9).

DANGER

Use only approved components in the fuel sup-

ply system. All components must be properly

installed in accordance with applicable codes.

Improper installation or use of unauthorized

components may result in fire or an explosion.

Follow approved methods to test the system

for leaks. No leakage is permitted. Do not allow

fuel vapors to enter the vehicle interior.

Figure 2.9 – Typical Propane Gas Fuel System

2.4.2 SOME IMPORTANT CONSIDERATIONS

When installing an LP gas system, consider seriously

the following items:

• All fittings, lines, hoses and clamps must be

tight and free of leaks. Apply a pipe sealant to

threads when assembling threaded connections.

This reduces the possibility of leakage.

• Test the entire fuel system for leaks using approved

test methods.

• Optimum gas pressure at the inlet to the gaseous

fuel solenoid valve and secondary regulator is 11

inches water column.

• The installer’s fuel supply connection point is at

the gaseous fuel solenoid valve. This is a 3/4-inch

(female) connection. Provide a suitable 3/4-inch

NPT (male) connector to attach to the fuel supply

line.

Section 2 – Installation

Recreational Vehicle Generator