7

This generator is not legal for sale in the state of California unless

all CARB evaporative emission requirements are adhered to, and

is not legal for sale in any other state unless certified low-per-

meation fuel line is used to supply the generator with gasoline.

Contact the California Air Resource Board or the Environmental

protection agency for further information. CARB regulations can

be found in 13 CCR §§2750 – 2773; EPA regulations can be

found in 40 CFR Part 90.

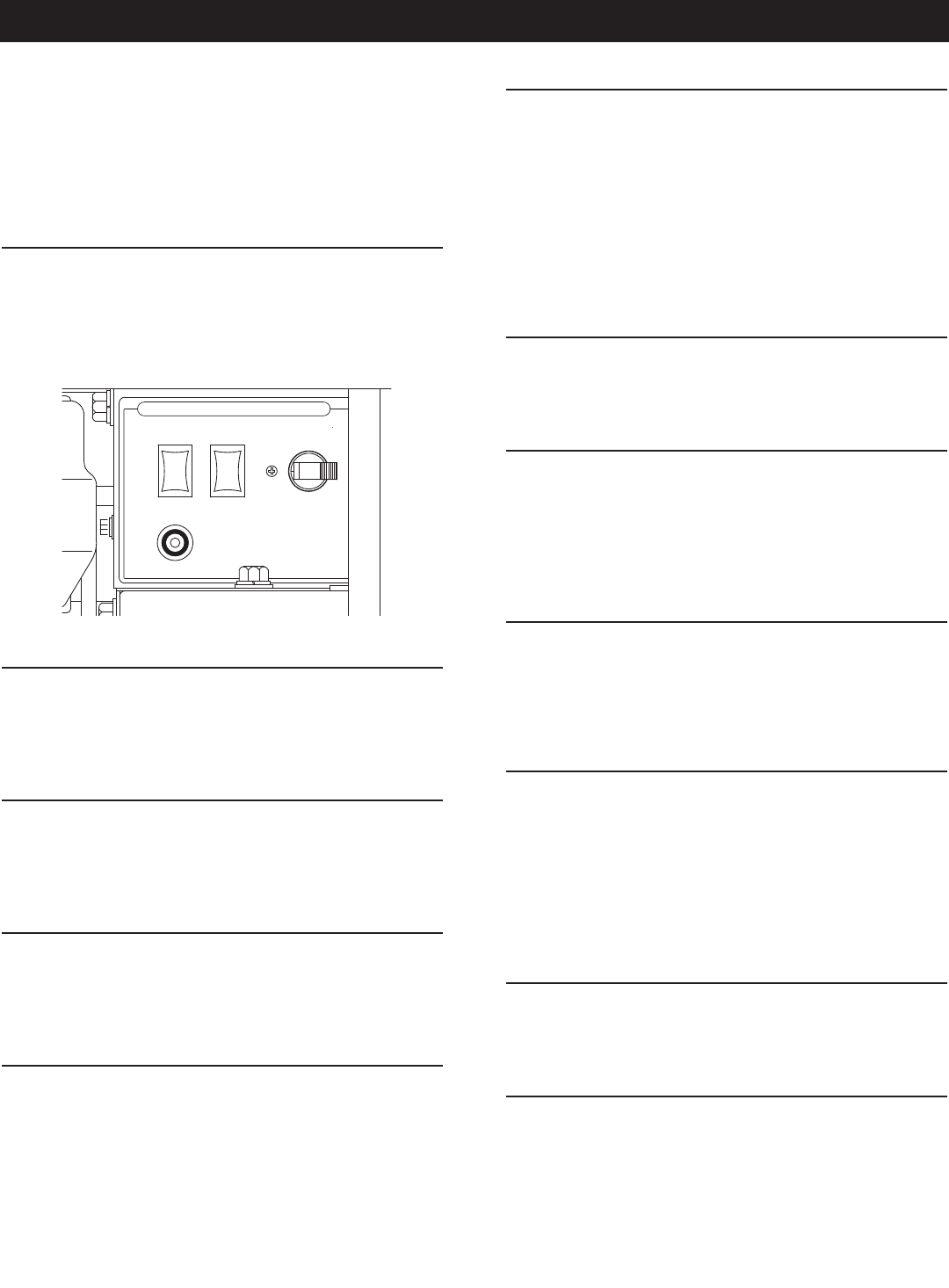

2.1 GENERATOR CONTROL PANEL

The following features are mounted on the generator control panel

(Figure 2.1):

Figure 2.1 – Generator Control Panel

PRIME

FUEL

STOP

START

30A

C.B.

FUSE

CONTROL CENTER

7. 5 A

2.1.1 FUEL PRIMER

Before starting a cold engine (if it has not been started in more

than two weeks), press this switch for approximately 10 to 15

seconds to bring fuel from the tank to the carburetor. This rocker

type switch springs back into its original position when released.

2.1.2 START/STOP SWITCH

To crank and start the engine, hold this switch in the START posi-

tion. Release the switch when the engine starts. To stop an operat-

ing engine, press and hold the switch in the STOP position until the

engine shuts off. The switch center position is the RUN position.

2.1.3 FUSE

The fuse protects the engine’s DC control circuit against electrical

overload. If the fuse element has melted open due to overloading,

the engine cannot be cranked. If the fuse must be replaced, use

only an identical replacement.

2.1.4 MAIN BREAKER

The main breaker protects the generator’s AC output circuit against

overload and provides a method of turning OFF the generator’s

120-volt AC output to the vehicle circuits. This generator has

30-amp breaker.

2.2 OPTIONAL REMOTE

START/STOP PANEL

A remote mounted Start/Stop Panel is available that allows start-

ing and stopping the generator engine conveniently from inside

the vehicle.

Order part number 0F0429 or 0F0430, a remote panel that includes

a Start/Stop switch, a generator run lamp, a fuel prime switch, and

an hourmeter. The hourmeter provides a continuous indication of

engine/generator operating time. Use the hourmeter for checking

off periodic maintenance requirements on the unit.

2.3 AUTOMATIC CHOKE

The engine is equipped with an automatic choke that consists of

two main components: a choke solenoid and prechoke.

2.3.1 CHOKE SOLENOID

During engine cranking (Start/Stop switch at START), a solid-state

choke module signals the choke solenoid to activate and cycle

(choke on/choke off) until the engine starts. The choke solenoid

thus opens and closes the carburetor choke valve only when the

engine is cranking. When the engine starts, the choke stops

cycling.

2.3.2 PRECHOKE

The choke system also has a temperature-sensitive metal strip that

adjusts choke valve angle according to ambient temperatures (i.e.,

in cold ambient temperatures, choke valve closes more). Once the

engine starts, an element heats the temperature-sensitive strip to

a normal operating condition, opening the choke valve. This may

take about three minutes in cooler weather.

2.4 BEFORE STARTING THE

ENGINE

NOTE:

Instructions and information in this manual assume the genera-

tor has been properly installed, connected, serviced, tested and

adjusted by a qualified installation technician or installation

contractor.

2.4.1 INSTALLATION

Generator installation must have been properly completed so it

complies with all applicable codes, standards and regulations and

with the manufacturer's recommendations.

2.4.2 ENGINE LUBRICATION

Have the engine crankcase properly serviced with the recommended

oil before starting. Refer to sections "Engine Oil Requiremtents",

"Checking the Engine Oil Level" and "Changing the Engine Oil and/

or Oil Filter" for oil servicing procedures and recommendations.

Operation