April 1, 2005 20 Lit. No. 94430/94431

PROBLEM POSSIBLE CAUSE SUGGESTED SOULUTION

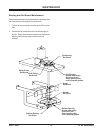

Ice control material not flowing

1. Bridging of material in hopper. 1. Unplug the spreader harness

and tag out if required. Check

hopper for material and free any

bridged material.

1. Drive belt is loose or damaged. 1. Unplug the spreader harness

and tag out if required.

Reconnect after solution.

Spinner does not turn

2. Motor pulley not secured to

motor shaft.

2. Adjust belt tension. Replace belt

if damaged.

(Spreader motor is running) 3. Spinner pulley is not secured to

the spinner shaft.

3. Tighten pulley set screw.

Replace pulley if damaged.

4. Spinner shaft bearings are dry or

seized.

4. Replace cap screw and nut if

missing or damaged. Replace

pulley if damaged.

1. Unplug the spreader harness

and tag out if required.

Reconnect after solution.

1. Drive belt is loose or damaged. 2. Adjust belt tension. Replace belt

if damaged.

2. Pulley is not secured to the

spinner shaft.

3. Tighten pulley set screw.

Replace pulley if damaged

3. Pulley is not secured to the

gearbox shaft.

4. Replace damaged or missing

key. Replace pulley if damaged.

Conveyor belt not moving

(Spinner is turning)

4. Gearbox is damaged. 5. Replace gearbox if output shaft

does not turn when input shaft

turns.

5. Conveyor rollers are not secured

to the shafts.

6. Replace missing cap screws and

nuts. Replace shafts or rollers if

damaged.

6. Conveyor belt is loose or

damaged.

7. Adjust belt tension. Replace belt

if damaged.

7. Conveyor belt is not aligned. 8. Align belt to ride centered on

rollers.

8. Conveyor belt shaft bearings are

seized or otherwise damaged.

9. Grease or replace bearings.

1. Unplug the spreader harness

and tag out if required.

Reconnect after solution.

Material in hopper does not flow

(Conveyor belt and spinner are

moving)

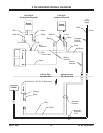

1. Feedgate is closed. 2. Open feedgate fully, then adjust

to desired opening size.

2. Obstruction in hopper. 3. Remove obstruction.

1. Unplug the spreader harness

and tag out if required.

Reconnect after solution.

Spread pattern not optimum

1. Deflector out of adjustment.

2. Change deflector adjustment to

suit desired pattern. (See

“Operating the Spreader” in this

manual.)

Mechanical Problems - Variable Speed (PWM) and ON/OFF Control

TROUBLESHOOTING