16

6. Tips and Troubleshooting

Your Exmark Ultra Vac QDS has been designed to be the most productive bagging system on

the market. The following tips have been collected to help you get the most out of your Ultra

Vac QDS right from the start.

6.1 When mowing in areas with sandy soil, use low lift blades on the cutting deck and

higher cutting heights to minimize wear on the blower components.

6.2 When mowing in wet conditions, such as just after a rain or in heavy dew, use low

lift blades on the cutting deck to minimize plugging of the blower.

6.3 When the bags get full, the sound of the blower will change and there will be slight

blowout from the front right corner of the deck. Emptying the bags at this point will

minimize the potential for the tube to plug.

6.4 If there is excessive blowout from the deck, check to make sure that the rear

screen in the hood is clear of grass build up. It is recommended that the screen

and mesh portions of the bags be cleaned regularly to maintain proper air flow.

This is especially important in wet conditions.

6.5 During dry conditions check engine air cleaners and clean cooling fins more

frequently. The Ultra Vac QDS has been designed to minimize the impact of dust

and debris on the mower, but bagging can be a dirty environment.

6.6 During dry conditions, switching to a lower lift blade may reduce blowout without

hurting quality of cut.

6.7 Maintaining a ground speed that does not pull down the engine RPM will allow for

the highest productivity and best quality of cut. Bogging the engine RPM down by

going too fast will cause plugging and quality of cut issues.

6.8 When storing the Ultra Vac QDS, it is recommended that any build up in the

blower be cleaned out. Dry grass build up may cause problems with the impeller

when the unit is put back into operation.

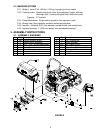

6.9 If the blower drive belt snaps or breaks frequently, check the alignment of the idler

arm per section 5. An arm that is bent out of position can cause the belt to jump

off of the idler and be cut by the sheaves.

6.10 If the idler pulley contacts the deck sheave, check the alignment of the idler arm

per section 5. Also check the mounting tube on the deck and the mounting pin on

the blower for bending or excessive wear. This condition is more likely to occur

with smaller deck sizes.

6.11 The condition of the belt drive is critical to proper operation. A sticking idler arm or

worn belt may cause plugging or blowout. Replace the belt when the idler arm is

riding on or near the stop.

6.12 Anti-blowout kits are available for leaf collection. They help to prevent “chasing”

the leaves. To reduce “plowing” leaves, raise the deck slightly.