Maintenance

Drive System Maintenance

Checking the Tire Pressure

Service Interval: Every 25 hours/Monthly

(whichever comes rst)

Maintain the air pressure in the front and rear tires as

specied. Uneven tire pressure can cause uneven cut.

Check the pressure at the valve stem (Figure 31).

Check the tires when they are cold to get the most

accurate pressure reading.

Rear Tires: 13 psi (90 kPa)

Front Tires (caster wheels):

• Smooth: 13 psi (90 kPa)

• Sawtooth: 20 psi (138 kPa)

Figure 31

1. Valve stem

Mower Maintenance

Servicing the Cutting Blades

Service Interval: Before each use or daily

Maintain sharp blades throughout the cutting season

because sharp blades cut cleanly without tearing or

shredding the grass blades. Tearing and shredding

turns grass brown at the edges, which slows growth

and increases the chance of disease.

Check the cutter blades daily for sharpness, and for

any wear or damage. File down any nicks and sharpen

the blades as necessary. If a blade is damaged or

worn, replace it immediately with a genuine Exmark

replacement blade. For convenient sharpening and

replacement, you may want to keep extra blades on

hand.

WARNING

A worn or damaged blade can break, and a

piece of the blade could be thrown into the

operator’s or bystander’s area, resulting in

serious personal injury or death.

• Inspect the blade periodically for wear or

damage.

• Replace a worn or damaged blade.

Before Inspecting or Servicing the

Blades

Park the machine on a level surface, disengage the

blade control switch, and move the motion control

levers outward to the neutral position and engage

parking brake. Stop the engine, remove the key, and

disconnect the spark plug wire(s) from the spark

plug(s).

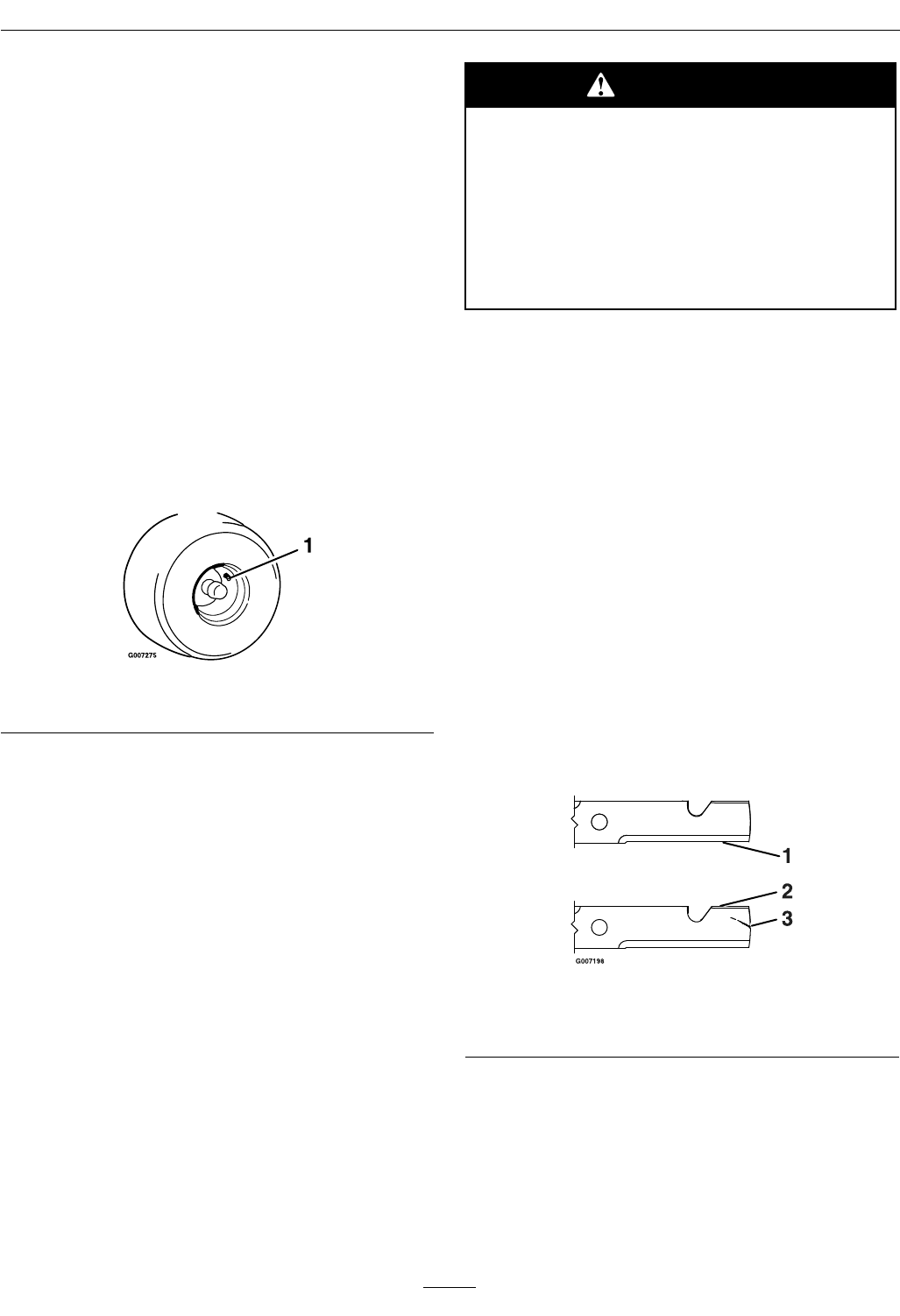

Inspecting the Blades

1. Inspect the cutting edges (Figure 32). If the edges

are not sharp or have nicks, remove and sharpen

the blades; refer to Sharpening the Blades.

2. Inspect the blades, especially the curved area. If

you notice any damage, wear, or a slot forming in

this area (item 3 in Figure 32), immediately install

a new blade.

Figure 32

1. Cutting edge 3. Wear/slot forming

2. Curved area

Checking for Bent Blades

1. Rotate the blades until the ends face forward and

backward (Figure 33 and Figure 34). Measure

from a level surface to the cutting edge, of the

blades. Note this dimension.

38