BEFORE EACH USE

• Check water inlet screen for damage.

• Check high pressure hose for leaks.

° Check detergent inlet hose and filter for damage.

• Check gun and wand assembly for leaks.

• Purge pump of air and contaminants.

• Check engine oil level.

PRESSURE WASHER MAINTENANCE

Check and Clean Inlet Screen: Remove quick-connect

and examine inlet screen on the female connector. Clean

if it is cloggedor replace if it is tom.

Check High Pressure Hose: High pressure hose can

developleaks from wear, kinking,abuse. Inspect hose

each timebefore using it. Check for cuts, leaks, abrasions

or bulgingof cover, or damage or movement of couplings.

If any of these conditionsexist, replace hose immediately.

,_ DANGER: Water spraying from a leak is

capable of injecting material into skin.

NEVER repair high pressure hose. Replace

with hose that meets minimum pressure rat-

-_ ing of your pressure washer.

Check Detergent Hose: Examine the filter on the deter-

gent hose and clean ifclogged. Hose should fit tightly on

barbed fitting. Examine hose for leaks or tears. Replace

the filter or hose if either is damaged.

Check Gun and Wand: Examine hose connectionto gun

and make sure it is secure. Test triggerby pressing it and

makingsure it springsback into place when you release it.

Put safety latch in UP positionand test trigger. You should

notbe able to press trigger.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps:

. Set up the pressure washer as described in the

ASSEMBLY section and connect the water supply.

° Remove'the nozzle extension from the gun.

o Pull the trigger on the gun and hold.

To remove the contaminants from the pump, follow these

steps:

• Set up the pressure washer as described in the

ASSEMBLY section, and connect the water supply.

• Remove the nozzle attachment from the gun.

° Start the engine according to instructions in OPER_,-

TION section.

o

O

Putt the trigger on the gun and hold.

When the water supply is steady and constant,

engage the safety latch and refasten the nozzle

attachment.

ENGINE MAINTENANCE

CHECKING OIL LEVEL

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

CHANGING ENGINE OIL

Change engine oil after first 2 hours then every 25 hours

thereafter. If you are using your pressure washer under

extremely dirty or dusty conditions, or in extremely hot

weather, change oil more often.

Change oil while engine is still warm from running, as

follows:

Disconnect spark plug wire from spark plug and keep

it away from spark plug.

Before you tip the pressure washer to drain oil, drain

fuel tank by running pressure washer until fuel tank is

empty.

Clean area around oil fill, remove oil fill cap/dipstick.

Wipe dipstickclean.

Tip your pressure washer to drain oil completelyfrom

the oil fill tube into a suitable container. When

crankcase is empty, returnthe pressure washer to

uprightposition.

Fill engine crankcase with recommended oil until oil

level is at FULL point on dipstick. Do not overfill above

that mark. POUR SLOWLY.

When engine crankcase is filled to proper level, install

and tighten oil cap/dipstick.

SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner.

Replace the air cleaner once every 100 hours of opera-

tion or once each year, whichever comes first. Replace

more often if operating under dirty or dusty conditions.

Replacements are available at your local Sears

Authorized Service Center.

Important: Do not attempt to clean or oilfilter.

Important: Never runengine without complete air clean-

er installed on engine.

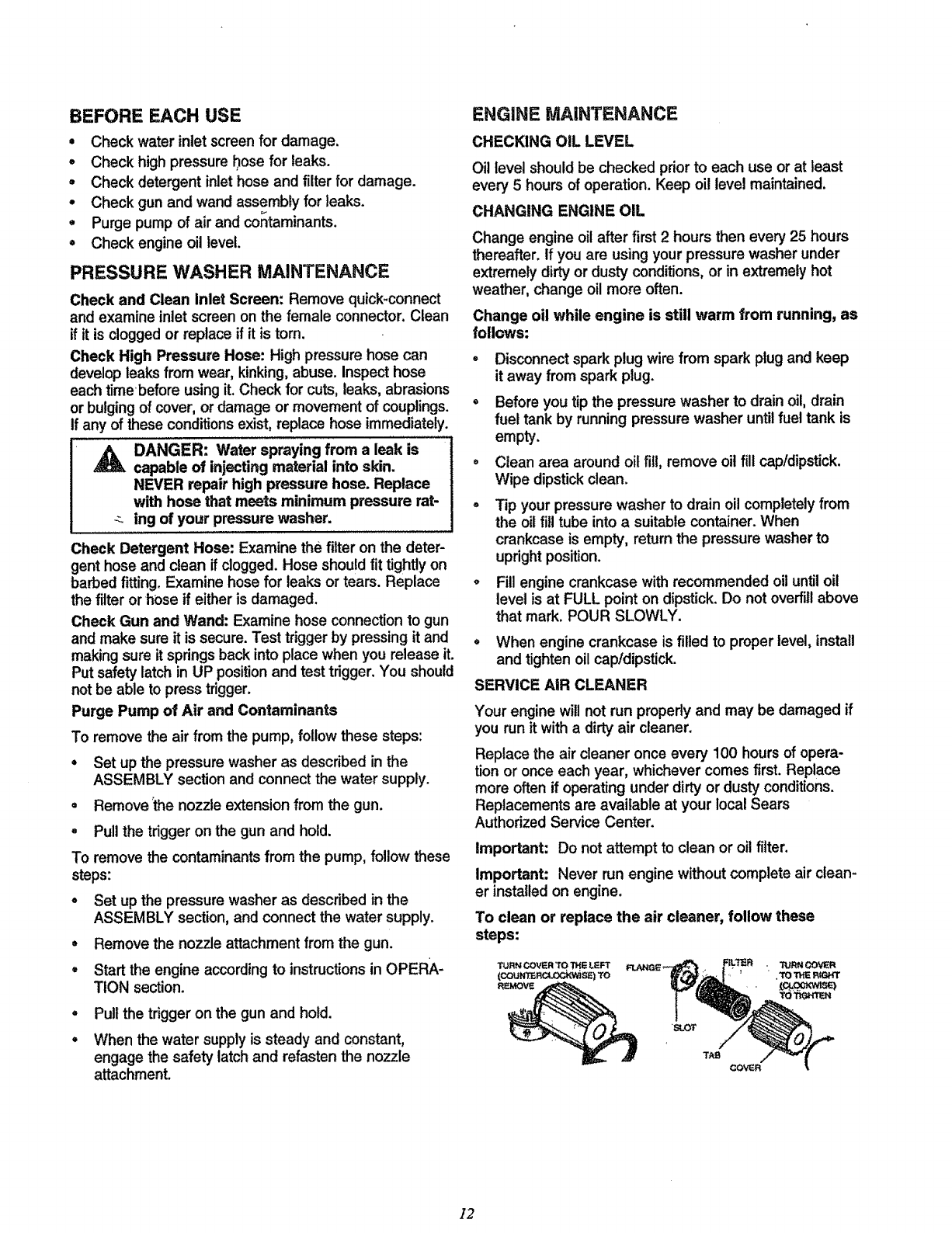

To clean or replace the air cleaner, follow these

steps:

TURN COVER 3"0 THELEFT _P,JRN GOVER

(COUNI_RCU:X;k_,_)'tO " .1'0THE I_r,rr

12