o

o

o

Turn cover to the left (counterclockwise) and

remove it and filter from flange. Discard filter.

Clean cover and flange thoroughly.

Insert new filter into cover.

Position cover and filterfirmly against flange with

tab on cover inserted into lower left comer of slot in

flange.

Push cover firmly against flange and turn it to the

right (clockwise) as far as it will go. Be sure retain-

ers are locked around flange.

CLEAN/REPLACE SPARK PLUG

Change the spark plug every 100 hours of operation or

once each year, whichever comes .first. This will help

your engine to start easier and run better. Replace with

champion RN4C or equivalent type spai'k plug.

Clean area around spark plug

Remove and inspect spark plug.

Replace spark plug if electrodes are pitted, burned

or porcelain is cracked. For replacement use

Champion RN4C only.

Check electrode gap withwire feeler gauge and set

gap at 0.030 (0.76mm) if necessary.

SET PLUG GAP AT 0.030 inch

(0.76 ram)

Shut off the engine and turn off the water supply.

Separate the nozzle from the nozzle extension,

o Rotate to stream setting.

,, Remove orifice from the end of the nozzle using the

allen wrench included with the kit or a 2ram or 5/64

allen wrench.

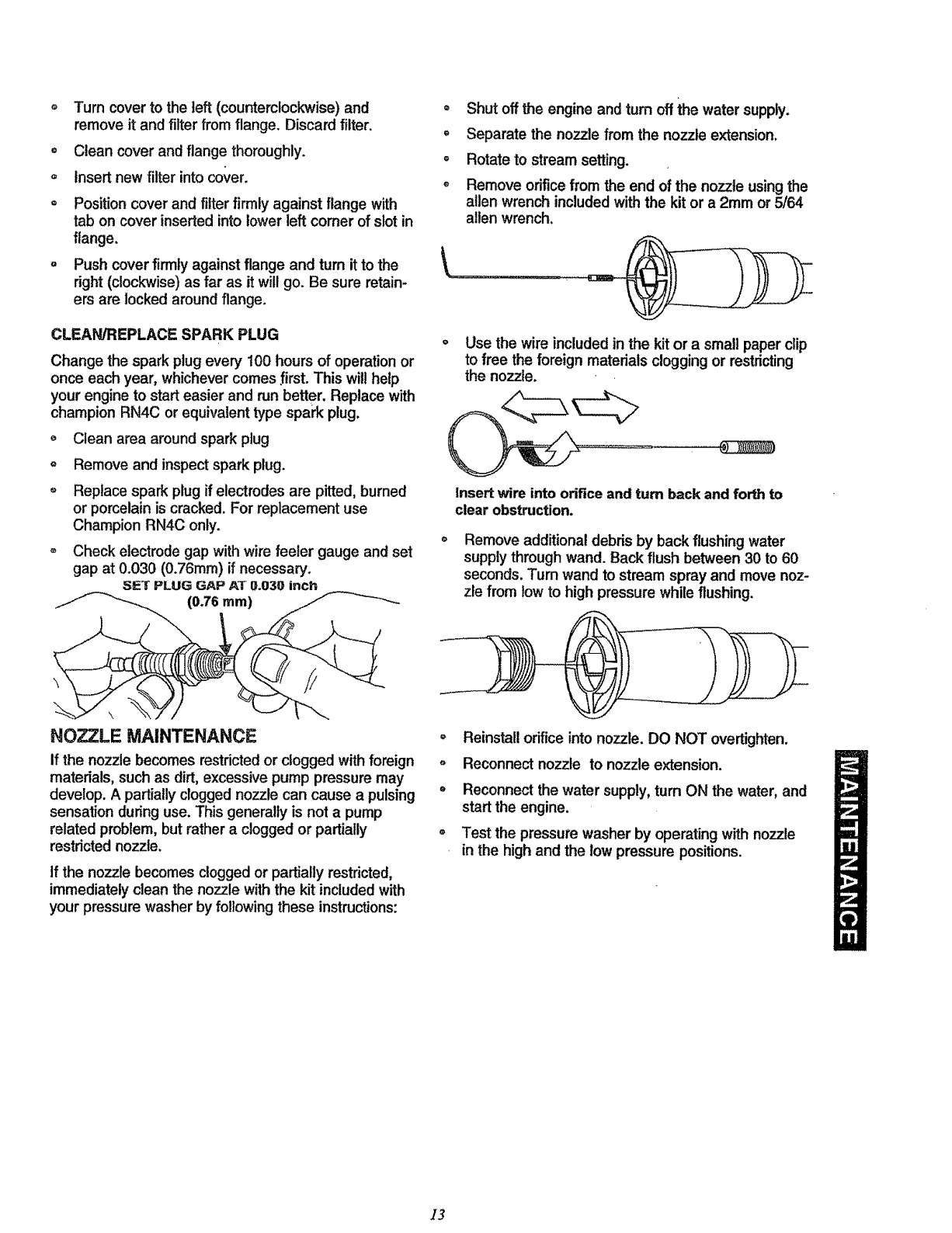

• Use the wire included in the kit or a small paper clip

to free the foreign materialsclogging or restricting

the nozzle.

insert wire into orifice and turn back and forth to

clear obstruction.

Remove additional debris by back flushing water

supply through wand. Back flush between 30 to 60

seconds. Turn wand to stream spray and move noz-

zle from tow to high pressure while flushing.

NOZZLE MAINTENANCE

If the nozzle becomes restrictedor clogged with foreign

materials, such as dirt, excessive pump pressure may

develop. A partially clogged nozzle can cause a pulsing

sensation during use. This generally is not a pump

related problem, but rather a clogged or partially

restricted nozzle.

If the nozzle becomes clogged or partially restricted,

immediately clean the nozzle with the kit included with

your pressure washer by following these instructions:

Reinstall orifice into nozzle. DO NOT overtighten.

o Reconnect nozzle to nozzle extension.

• Reconnect the water supply, turn ON the water, and

start the engine.

- Test the pressure washer by operating with nozzle

in the high and the tow pressure positions.

!3