NEUTRAL ADJUSTMENT - DRIVE

1. Raise the drive wheels of the Zero Turn off of the

ground. Safely block the frame in this position so it is

secure.

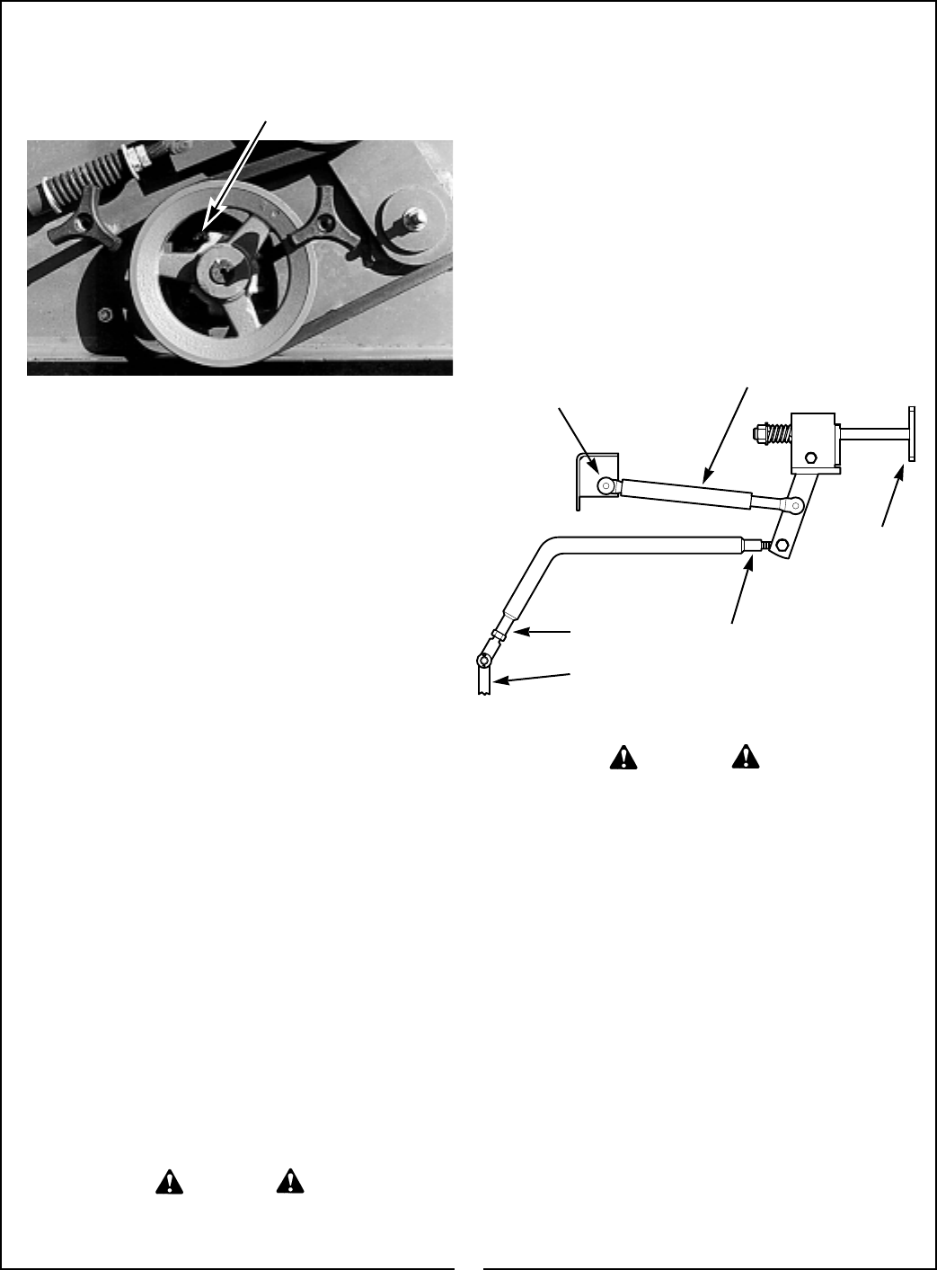

2. Check to be sure the self centering dampener is

in synchronized with the control levers. (Pull back on

control levers and let go; they should return to the

neutral location.) This is adjusted by locking the con-

trol lever in the neutral position (swung out) and

loosening the retainer nut on the self centering

dampener located on either side of the seat frame.

Allow the self centering dampener to locate the posi-

tion in the slot and retighten the nut.

3. With the operator in the seat, start the engine,

leaving the control levers in the neutral position.

Release the parking brake. Check drive wheels for

any rotation.

4. Stop engine and engage parking brake. If the

drive wheels creeped (rotated) in the neutral position

this should be adjusted out. This adjustment is per-

formed at the adjustable pump link on each corre-

sponding pump. Make the adjustment by either

lengthening or shortening the distance of the adjust-

ing links. If the wheel rotates in the forward direction,

shorten the rod. If the wheel rotates in the reverse

direction, lengthen the rod. Retighten the jam nut.

Start the engine and recheckthe adjustment.

5. If wheel still creeps, repeat procedure in step 4.

6. After final adjustment is made (make sure that

the jam nut is tight on pump link), take unit for a test

drive.

DRIVE ADJUSTMENTS

Steering and motion controls should be uniform in all

forward and reverse speeds. Levers should automat-

ically return to neutral when released.

CAUTION

STOP THE ENGINE BEFORE MAKING

ADJUSTMENTS.

TEST DRIVE OPERATIONS

Check air pressure in tires. Equal tire pressure is

critical for proper drive operation.

1. Raise drive wheels off ground. Safely block

the frame in this position.

2. Put control levers in neutral lock position

(control levers swung outward).

3. Start engine.

Wheels should not rotate. If one or both drive wheels

are turning, perform procedures under “Neutral

Adjustments” for side(s) that wheel turns.

LEVELING THE DECK

1. Set all tire pressures to correct specifications.

2. Place machine on a level slab of concrete.

3. Lower the deck to ground level.

4. (SIDE TO SIDE) Wear heavy gloves and posi-

tion the blades by hand so all the blades are pointed

in the same direction from “SIDE TO SIDE”.

Measure from the blade tip (beveled edge) to the

ground on all three blades. If there is more than

3/16” difference from one side to the other, the deck

should be leveled.

5. Correct the difference by shortening or lengthen-

ing the side adjusting links. To raise the deck, short-

en the length of the adjusting link. To lower the

deck, lengthen the adjusting link.

6. (FRONT TO REAR) Wear heavy gloves and posi-

tion the blades by hand so all the blades are pointed

in the same direction from “FRONT TO REAR”.

15

CAUTION

STOP ENGINE, SET PARKING BRAKE, REMOVE

IGNITION KEY AND SPARK PLUG WIRES

FOR SAFETY

7. GREASING TOP BEARING IN GEARBOX

Grease top bearing with grease gun (1-2 shots)

every 50 hours.

Grease Fitting For Top Bearing

Self Centering Dampener

Slotted Hole With

Retaining Nut On Back Side

Pump LInk Adjustments

Pump Arm

Control Lever

Mounting Plate