1. ENGINE:

For complete maintenance and operating infor-

mation for your engine, please refer to your

engine operating and maintenance instructions

furnished by the engine manufacturer and includ-

ed in your Zero Turn mower information packet.

NOTE

Air intake screen must be kept clean. If

plugged, engine may be seriously dam-

aged by over heating.

2. BATTERY:

When taking the battery out of the mower for ser

vicing, make sure to reconnect the cables to the

battery exactly as they were prior to removal.

Keep the battery clean. Remove the corrosion

around the battery terminals by applying a solu-

tion of one part baking soda to four parts water.

Coat all exposed terminal surfaces with a light

layer of grease or petroleum jell to prevent corro-

sion.

NOTE

At temperatures below 32 degrees F (0 deg

C) the full charge state must be maintained to

prevent cell electrolyte from freezing and

causing permanent battery damage.

3. TIRES:

Correct tire pressure is essential for efficient

operation of the mower. Check tire air pres-

sure periodically. Inflate tires to the pressure

listed:

TIRE PRESSURE

Front Tires

Drive Tires Rear Tires

11” Sealant Filled 20” 13” 18 psi

22 psi Turf Tire - 22 psi

Bar Tire - 22 psi

Knobby Tire (ATV Type) - 5 psi

AVOID SERIOUS INJURY OR DEATH:

● THE BATTERY CONTAINS SULFURIC ACID.

AVOID CONTACT WITH SKIN, EYES OR CLOTHING.

EYES - FLUSH WITH WATER AND GET PROMPT MED-

ICAL ATTENTION.

ANTIDOTE: INTERNAL - DRINK LARGE QUANTITIES

OF WATER OR MILK. FOLLOW WITH MILK OF MAG-

NESIA, BEATEN EGG OR VEGETABLE OIL. CALL A

PHYSICIAN IMMEDIATELY.

● BATTERIES PRODUCE EXPLOSIVE GASES.

KEEP SPARKS, FLAMES AND SMOKING MATERI-

ALS AWAY. VENTILATE WHEN CHARGING IN AN

ENCLOSED SPACE. WEAR EYE PROTECTION

WHEN WORKING NEAR BATTERIES.

● KEEP OUT OF REACH OF CHILDREN.

4. MOWER BLADES:

Check sharpness of mower blades after every 10

hours of operation. To sharpen blades proceed as

follows:

A. Tilt deck up into raised position and secure with

deck pins.

B. Remove bolt, cup washer, and blade from shaft.

C Blades should be discarded when worn exces-

sively. See sketch.

D. Sharpen blade with a hand file, electric grinder

or blade sharpener. Wear gloves and eye protection

when sharpening. Grind blade at original bevel.

E. Check balance of blade by positioning the blade

on a nail or blade balance pedestal. Grind the blade

on the end that is heavier until both sides balance.

F. Install blades with the concave side of the cup

washer against blade. Be sure blades are installed

with uplifts and cutting edges in the proper directions.

Tighten retaining bolt to 76 ft./lbs.

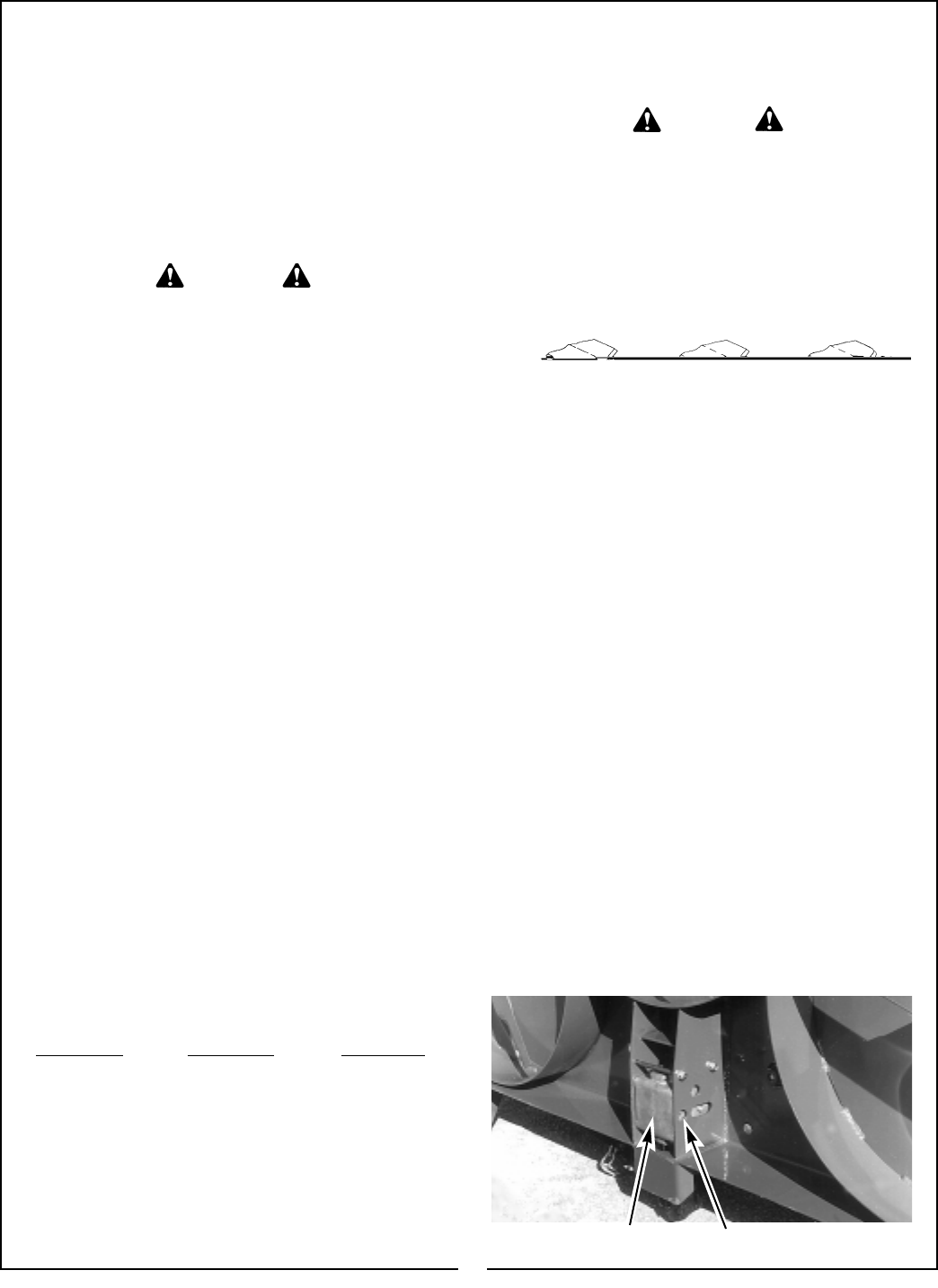

5. CHECKING DECK DRIVE GEARBOX FLUID LEVEL

A. Rotate deck into the upright position and

secure with deck pins.

B. Remove the hex head plug at the low end of

the gearbox housing. (Plug closest to the drive

shaft.) The fluid level should be level with the bottom

of the threaded hole.

6. CHANGING FLUID IN DECK DRIVE GEARBOX

(Annually or every 500 hours)

A. Rotate the deck into the upright position,

secure deck with pins and remove drain plug from

bottom edge of gearbox.

B. Lower deck to drain fluid.

C. When the fluid has drained from the gearbox,

raise deck back up and fill with Mobil SHC 630

synthetic motor oil (or EP 80W90). Fill to the bot-

tom of the hole that the plug was removed from.

D. Reinstall drain plug.

14

CAUTION

STOP ENGINE, SET PARKING BRAKE,

REMOVE IGNITION KEY AND SPARK PLUGS

FOR SAFETY.

New Blade

Dangerous!

25 Degrees

When Notch Starts

Discard Blade

Deck Drive Gearbox Drain/Fill/Check Plug

WARNING

Lug nuts should be checked regularly for tight-

ness. Torque lug nuts to 50 ft./lbs. The center

hub nut should be torqued to 175 - 200 ft./lbs.

and cotter key installed.