Hydraulic Hook-Up (865H & 965H)

For Tractors With Closed-Center Hydraulic Systems

There are two basic types of hydraulic systems, open-

center and closed-center. The open-center system con-

stantly pumps oil through the hydraulic cylinder operat-

ing valves and returns the oil to the reservoir. The

closed-center system does not pump oil until there is a

demand for oil from one of the hydraulic cylinders.

In this case, CLOSED-CENTER means that when the

operating valves which control the hydraulic cylinders

are in the neutral position, there is no flow of oil through

the valves. As long as the engine and pump are run-

ning, a constant stand-by oil pressure of approximately

2000 PSI or more is maintained in the system. Pressure

oil is available instantaneously to go to work when any

one of the operating valves is opened.

Because there must be no flow through the backhoe

control valve, when the levers are in neutral position, the

backhoe must be converted for closed-center operation.

Hook-Up Requirements

The hook-up of the 865H & 965H Backhoes to the

closed-center system requires more than connecting it

to the remote couplers. The required devices are:

1. A flow restrictor in the pressure line to keep the speed

of the backhoe operation within safe and acceptable limits.

2. A main relief valve in the backhoe control valve with a

pressure setting that is always higher than the tractor

system pressure.

3. A closed-center plug in the backhoe control valve to

make it a non-circulating or a demand type system.

4. A low pressure surge relief valve in the return line

to keep the tractor back pressure surges from dam-

aging the backhoe control valve seals or tractor sys-

tem. A surplus flow line from the relief valve carries only

the excess surge oil directly back to the tractor hydraulic

reservoir so that it bypasses all other tractor functions.

Backhoe Operation

For the most part, a backhoe will function about the

same whether it is powered by an open-center or

closed-center hydraulic system. However, there are

some differences which the operator should be aware of.

As a backhoe function (lifting, actuating the bucket to fill

it, etc.) becomes increasingly difficult and the hydraulic

system pressure is rising closer to its maximum setting,

there will be a noticeable slow down before stoppage

occurs. As the system pressure is approaching maxi-

mum, the pump is also beginning to stroke back for less

and less fluid delivery. At maximum pressure, the pump

is completely destroked and there is no delivery.

Therefore, when working various backhoe functions at

near maximum ability, it will give the operator the

impression that the backhoe is sluggish and somewhat

unresponsive. Learning to ease up slightly at the first

indication of slow down will permit the backhoe to per-

form at continuing maximum speed and efficiency.

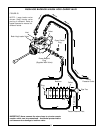

Hook-Up Diagram

For John Deere Tractors use reservoir plug. Remove

plug, drill with 37/64 drill, and tap 3/8 NPT pipe. Screw

plug onto hose, locking with Locktite to assure

assembly will remain together during connecting

and disconnecting procedures. Obtain another plug

from your dealer to use when backhoe is removed.

For other tractor makes, use filler plug, drain plug,

or any other port that goes directly into the hydraulic

reservoir. Do not rely only on the remote coupler

return.

Typical plug for surplus relief flow line. Check care-

fully that it enters the reservoir before using. Note

that the location varies with different tractor makes

and models. A John Deere Tractor is shown.

JOHN DEERE - DIAL APPROXIMATELY

AS SHOWN

Figure 20

27

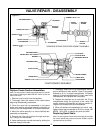

Figure 19

Replace 2400 PSI relief valve (865H) or

2250 PSI (965H) with 2600 PSI relief

valve.

BACKHOE VALVE

Tractor

Coupler

Tip

Replace open-center

plug with closed-center

plug, shown.

1

4

7

6

1

2

3

5